Abstract

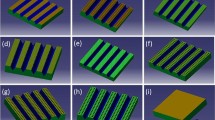

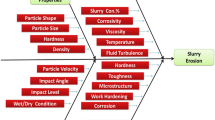

A three levels orthogonal table- L9(34) was used, namely, impact angle, rotating speed, erodent size, and surface configuration were considered. The three bionic surface configurations are pit, groove, and ring. The experimental results indicate the experiment factors affecting erosive rate are, in their sequence of contribution, erodent size, impact angle, configuration, and rotating speed; the erosive rate increased with increase in rotating speed, erodent size; the erosion resistance of the sample with ring structure is higher than that of the other two samples. Based on this result, regression orthogonal experiment was carried out to select the optimal erosion resistance condition with respect to the ring bionic surface configuration. Regression equations between erosive rate and experimental factors of ring surface configurations were obtained.

Similar content being viewed by others

References

Harsha AP, Jha, SK. Erosive Wear Studies of Epoxy-based Composites at Normal Incidence[J]. Wear, 2008, 265(7–8): 1129–1135

Du XD, Ding HF, Wang K, et al. Influence of Impact Energy on Impact Corrosion-abrasion of High Manganese Steel[J]. Journal of Wuhan University of Technology-Materials Science Edition, 2007, 22: 412–416

Yaer XB, Shimizu K, Matsumoto, H, et al. Erosive Wear Characteristics of Spheroidal Carbides Cast Iron[J]. Wear, 2008, 264(11–12): 947–957

Dong Gang, Zhang JiuYuan. Developments of Research on the Solid Particle Erosion of Materials[J]. Materials Science and Engineering, 2003, 21(2): 307–312

Bai W J. Research on Erosion Action and Mechanism of Materials[J]. Zhe Jiang Chemical Industry, 2004, 35(11): 17–20

Ma Ying, Ren Jun, Li YuanDong, et al. Development of Research on Erosion of Materials[J]. Journal of Lanzhou Institute of Technology, 2005, 31(1): 21–25

Lin JianZhong, Wu FaLi, Yu ZhaoSheng. A New Way to Reduce Wall Erosion Caused by Solid Particles[J]. Tribology, 2003, 23(3): 231–234

Irina Hussainova. Klaus-Peter Schade Correlation Between Solid Particle Erosion of Cermets and Particle Impact Dynamics[J]. Tribology International, 2008, 41(4): 323–330

Arjula S, Harsha AP, Ghosh MK. Solid-particle Erosion Behavior of High-performance Thermoplastic Polymers[J]. Journal of Materials Science, 2008, 43(6): 1757–1768

Desale GR, Paul CP, Gandhi, BK, et al. Erosion Wear Behavior of Laser Clad Surfaces of low Carbon Austenitic Steel[J]. Wear, 2009, 266(9–10): 975–987

Desale G R, Gandhi B K, Jain S C. Effect of Erodent Properties on Erosion Wear of Ductile Type Materials[J]. Wear, 2006, 261(7–8): 914–921

Mahapatra SS, Patnaik A, Satapathy, A. Taguchi Method Applied to Parametric Appraisal of Erosion Behavior of GF-reinforced Polyester Composites[J]. Wear, 2008, 265(1–2): 214–222

He P, Wang W M, Dong Y L. Thermal Shock Resistance and Erosion Resistance of TiB2 Multiphase Ceramic Composites[J]. Journal of Wuhan University of Technology-Materials Science Edition, 2006, 21(4): 117–120

Srivastava VK, Pawar AG. Solid Particle Erosion of Glass Fibre Reinforced Flyash Filled Epoxy Resin Composites[J]. Composites Science and Technology, 2006, 66(15): 3021–3028

Ren Luquan, Tong Jin, Li Jianqiao, et al. Soil Adhesion and Biomimetics of Soil-engaging Components in Anti-adhesion Against Soil: A Review[J]. Journal of Agricultural Engineering Research, 2001, 79(3): 239–263

Han Zhiwu, Xu Xiaoxia, Ren Luquan. Regression Analysis of Micro-friction and Wear on Concave Non-smooth Surface[J]. Tribology, 2005, 25(6): 578–582

Han Zhiwu, Ren Luquan, Liu Zubin. Investigation on Anti-wear Ability of Bionic Nonsmooth Surfaces Made by Laser Texturing[J]. Tribology, 2004, 24(4): 289–293

Satapathy A, Patnaik, A, Pradhan MK. A Study on Processing, Characterization and Erosion Behavior of fish (Labeo-rohita) Scale Filled Epoxy Matrix Composites[J]. Materials and Design, 2009, 30(7): 2359–2371

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Natural Science Foundation of China (No. 50635030), the Scientific and Technological Development Project of Jilin Province(No. 20090340), the Doctoral Program Foundation of Institutions of Higher Education of China(No.20100061110023), the Projects of Cooperation and Innovation to National Potential Oil and Gas for Production and Research, the Public Benefit Research Sector to Ministry and Resources(No. Sinoprobe09-01-07), and the Graduate Innovation Fund of Jilin University(No.20091015)

Rights and permissions

About this article

Cite this article

Han, Z., Zhang, J., Ge, C. et al. Gas-solid erosion on bionic configuration surface. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 26, 305–310 (2011). https://doi.org/10.1007/s11595-011-0219-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-011-0219-z