Abstract

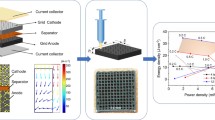

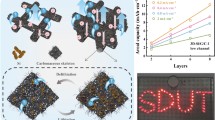

Lithium-ion micro-batteries (LIMBs) with higher energy density have drawn extensive attention. 3D printing technique based on direct ink writing (DIW) is a low-cost and simple approach to fabricate LIMBs especially with higher areal capacity. Herein, poly(3,4-ethylenedioxythiophene):polystyrene sulfonate (PEDOT:PSS) nanofibrils are first combined with carbon methyl cellulose (CMC) to achieve the 3D printing of thick LFP (LiFePO4)-PEDOT-CMC electrodes at room temperature by DIW. 3D-printed PEDOT-CMC-based composite thick electrodes demonstrate high conductivity because of the interconnected 3D network including hierarchical macro-micro porous criss-crossing filaments which can provide effective transport paths for Li ions and electrons. Further, LFP-PEDOT-CMC electrodes of different thicknesses are 3D-printed to study the effect of thicknesses on the electrochemical performances. The 3D-printed ultra-thick LFP-CMC-PEDOT electrode of 1.43 mm thickness at lower rate exhibits a highly improved areal capacity (5.63 mAh cm−2, 0.2 C) and high capacity retention (after 100 cycles, 0.2 C, 92%). The rate capability decreases steadily with the increasing thickness. However, for the extra-thick electrodes greater than 1.43 mm thickness, the discharge capacity, rate, and cycle capability decline dramatically. Electrochemical impedance spectroscopy measurements are used to explain the kinetic mechanism. For 3D-printed LFP-CMC-PEDOT electrodes blow 1.43 mm thickness, the 3D network plays the dominant role to maintain the effective transmission dynamics regardless of electrode thickness. But for the extra-thick electrodes, the greater transport distance becomes the major limiting factor resulting in the degradation of electrochemical performances. This work will offer guidance on how to apply 3D-printed ultra-thick electrodes with high energy density to LIMBs.

Similar content being viewed by others

References

Chen RS, Li QH, Yu XQ, Chen L, Li H (2020) Approaching practically accessible solid-state batteries: stability issues related to solid electrolytes and interfaces. Chem Rev 120:6820–6877

Mackanic DG, Chang TH, Huang ZJ, Cui Y, Bao Z (2020) Stretchable electrochemical energy storage devices. Chem Soc Rev 49:4466–4495

Chen D, Lou Z, Jiang K, Shen G (2018) Device configurations and future prospects of flexible/stretchable lithium-ion batteries. Adv Funct Mater 28:1805596

Zubi G, Dufo-Lopez R, Carvalho M et al (2018) The lithium-ion battery: state of the art and future perspectives. Renew Sust Energy 89:292–308

Nasreldin M, Delattre R, Calmes C, Ramuz M, Sugiawati VA, Maria S, Tocnaye JLB, Djenizian T (2020) High performance stretchable Li-ion microbattery. Energy Storage Mater 33:108–115

Liu QW, Zhang GF, Chen N, Feng X, Wang C, Wang J, Jin X, Qu L (2020) The first flexible dual-ion microbattery demonstrates superior capacity and ultrahigh energy density: small and powerful. Adv Funct Mater 30:2002086

Li WH, Christiansen TL, Li C, Zhou YL, Fei H, Mamakhel A, Iversen BB, Watkins JJ (2018) High-power lithium-ion microbatteries from imprinted 3D electrodes of sub-10 nm LiMn2O4/Li4Ti5O12 nanocrystals and a copolymer gel electrolyte. Nano Energy 52:431–440

Salian GD, Lebouin C, Demoulin A, Lepihin MS, Maria S, Galeyeva AK, Kurbatov AP, Djenizian T (2017) Electrodeposition of polymer electrolyte in nanostructured electrodes for enhanced electrochemical performance of thin-film Li-ion microbatteries. J Power Sources 340:242–246

Zhao QN, Zhao KQ, Ji GP, Guo X, Han M, Wen J, Ren Z, Zhao S, Gao Z, Wang R, Li M, Sun K, Hu N, Xu C (2019) High sulfur loading, rGO-linked and polymer binder-free cathodes based on rGO wrapped N, P-codoped mesoporous carbon as sulfur host for Li-S batteries. Chem Eng J 361:1043–1052

Guo QZ, Guo XH, Du KQ et al (2015) Superior high-rate capability of hierarchically structured flower-like magnetite-carbon-graphene composite for Li-ion anode. Int J Hydrog Energy 40:1846–1851

Xue XY, Zhang H, Yuan S, Shi L, Zhao Y, Wang Z, Chen H, Zhu J (2020) PEDOT:PSS @molecular sieve as dual-functional additive to enhance electrochemical performance and stability of Ni-rich NMC lithium-ion batteries. Energy Technol 8:2000339

Lv D, Zheng J, Li Q, Xie X, Ferrara S, Nie Z, Mehdi LB, Browning ND, Zhang JG, Graff GL, Liu J, Xiao J (2015) High energy density lithium-sulfur batteries: challenges of thick sulfur cathodes. Adv Energy Mater 5:1402290

Egorov V, Gulzar U, Zhang Y, Breen S, O'Dwyer C (2020) Evolution of 3D printing method and materials for electrochemical energy storage. Adv Mater 32:2000556

ASTM52900 – 15 (2016) Standard terminology for additive manufacturing general principles – Terminology. ASTM International, West Conshohocken

Zhang YB, Shi G, Qin JD, Lowe SE, Zhang S, Zhao H, Zhong YL (2019) Recent progress of direct ink writing of electronic components for advanced wearable devices. ACS Appl Electron Mater 1:1718–1734

Sun K, Wei TS, Ahn BY, Seo JY, Dillon SJ, Lewis JA (2013) 3D Printing of interdigitated Li-ion microbattery architectures. Adv Mater 25:4539–4543

Wei TS, Ahn BY, Grotto J, Lewis JA (2018) 3D Printing of customized Li-ion batteries with thick electrodes. Adv Mater 30:1703027

Cao DX, Xing YJ, Tantratian K, Wang X, Ma Y, Mukhopadhyay A, Cheng Z, Zhang Q, Jiao Y, Chen L, Zhu H (2019) 3D printed high-performance lithium metal microbatteries enabled by nanocellulose. Adv Mater 31:1807313

Dai L, Cheng T, Duan C, Zhao W, Zhang W, Zou X, Aspler J, Ni Y (2019) 3D printing using plant-derived cellulose and its derivatives: a review. Carbohydr Polym 203:71–86

Wang QQ, Sun JZ, Yao Q, Ji C, Liu J, Zhu Q (2018) 3D printing with cellulose materials. Cellulose 25:4275–4301

Liu CY, Xu F, Liu YL, Ma J, Liu P, Wang D, Lao C, Chen Z (2019) High mass loading ultrathick porous Li4Ti5O12 electrodes with improved areal capacity fabricated via low temperature direct writing. Electrochim Acta 314:81–88

Wang Y, Zhu CX, Pfattner R et al (2017) A highly stretchable, transparent, and conductive polymer. Sci Adv 3:e1602076

Rivnay J, Inal S, Collins BA, Sessolo M, Stavrinidou E, Strakosas X, Tassone C, Delongchamp DM, Malliaras GG (2016) Structural control of mixed ionic and electronic transport in conducting polymers. Nat Commun 7:11287

Zhang SM, Chen YH, Liu H et al (2019) Room-temperature-formed PEDOT:PSS hydrogels enable injectable, soft, and healable organic bioelectronics. Adv Mater 32:1904752

Liu Y, Tang DP, Zhong HX, Zhang Q, Yang J, Zhang L (2016) Facial synthesis of nanostructured Li4Ti5O12/PEDOT:PSS composite as anode material for lithium-ion batteries. RSC Adv 6:95512–95517

Das PR, Komsiyska L, Osters O, Wittstock G (2015) PEDOT: PSS as a functional binder for cathodes in lithium ion batteries. J Electrochem Soc 162:A674–A678

Sandu G, Ernould B, Rolland J, Cheminet N, Brassinne J, Das PR, Filinchuk Y, Cheng L, Komsiyska L, Dubois P, Melinte S, Gohy JF, Lazzaroni R, Vlad A (2017) Mechanochemical synthesis of PEDOT:PSS hydrogels for aqueous formulation of Li-ion battery electrodes. ACS Appl Mater Interfaces 9:34865–34874

Yuk H, Lu BY, Lin S, Qu K, Xu J, Luo J, Zhao X (2020) 3D printing of conducting polymers. Nat Commun 11:1604

Naficy S, Jalili R, Aboutalebi SH, Gorkin III RA, Konstantinov K, Innis PC, Spinks GM, Poulin P, Wallace GG (2014) Graphene oxide dispersions: tuning rheology to enable fabrication. Mater Horiz 1:326–331

Sander JS, Erb RM, Li L et al (2016) High-performance battery electrodes via magnetic templating. Nat Energy 1:16099

Kuang YD, Chen CJ, Pastel G et al (2018) Conductive cellulose nanofiber enabled thick electrode for compact and flexible energy storage devices. Adv Energy Mater 8:1802398

Leaf MA, Muthukumar M (2016) Electrostatic effect on the solution structure and dynamics of PEDOT:PSS. Macromolecules 49:4286–4294

Eliseeva SN, Apraksin RV, Tolstopjatova EG, Kondratiev VV (2017) Electrochemical impedance spectroscopy characterization of LiFePO4 cathode material with carboxymethylcellulose and poly-3,4- ethylendioxythiophene/polystyrene sulfonate. Electrochim Acta 227:357–366

Lama M, Boor SL, Raed H (2016) Carbon nanostructures modified LiFePO4 cathodes for lithium ion battery applications: optimized porosity and composition. Mater Res Express 12:125008

Raj H, Rani S, Sil A (2018) Antisite defects in sol-gel-synthesized LiFePO4 at higher temperature: effect on lithium-ion diffusion. ChemElectroChem 5:3525–3532

Li Y, Wang J, Fu CC et al (2020) LiFePO4/C nanoparticle with fast ion/electron transfer capability obtained by adjusting pH values. J Mater Sci 56:640–648

Funding

The work is supported by the National Undergraduate Innovation and Entrepreneurship Training Program in China (202010731020).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bao, P., Lu, Y., Tao, P. et al. 3D printing PEDOT-CMC-based high areal capacity electrodes for Li-ion batteries. Ionics 27, 2857–2865 (2021). https://doi.org/10.1007/s11581-021-04063-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-021-04063-4