Abstract

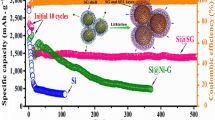

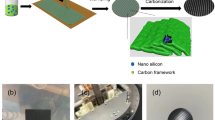

Nanostructured silicon anodes have shown extraordinary lithium storage properties for lithium-ion batteries (LIBs) but are usually achieved at low areal loadings (< 1.5 mg·cm−2) with low areal capacity. Sustaining sound electrochemical performance at high loading requires proportionally higher ion/electron currents and robust structural stability in the thicker electrode. Herein, we report a three-dimensional (3D) printed silicon-graphene-carbon nanotube (3D-Si/G/C) electrode for simultaneously achieving ultrahigh areal/gravimetric capacities at high mass loading. The periodically arranged vertical channels and hierarchically porous filaments facilitate sufficient electrolyte infiltration and rapid ion diffusion, and the carbonaceous network provides excellent electron transport properties and mechanical integrity, thus endowing the printed 3D-Si/G/C electrode with fast electrochemical reaction kinetics and reversibility at high mass loading. Consequently, the 3D-Si/G/C with high areal mass loading of 12.9 mg·cm−2 exhibits excellent areal capacity of 12.8 mAh·cm−2 and specific capacity of 1007 mAh·g−1, respectively. In-situ optical microscope and ex-situ scanning electron microscope (SEM) confirm that the hierarchically porous filaments with interconnected carbon skeletons effectively suppress the volume change of silicon and maintain stable micro-lattice architecture. A 3D printed 3D-Si/G/C-1∥3D-LiFePO4/G full cell holds excellent cyclic stability (capacity retention rate of 78% after 50 cycles) with an initial Coulombic efficiency (ICE) of 96%. This work validates the feasibility of 3D printing on constructing high mass loading silicon anode for practical high energy-density LIBs.

Similar content being viewed by others

References

Teki, R.; Datta, M. K.; Krishnan, R.; Parker, T. C.; Lu, T. M.; Kumta, P. N.; Koratkar, N. Nanostructured silicon anodes for lithium ion rechargeable batteries. Small 2009, 5, 2236–2242.

Wang, B.; Ryu, J.; Choi, S.; Zhang, X. H.; Pribat, D.; Li, X. L.; Zhi, L. J.; Park, S.; Ruoff, R. S. Ultrafast-charging silicon-based corallike network anodes for lithium-ion batteries with high energy and power densities. ACS Nano 2019, 13, 2307–2315.

An, Y. L.; Fei, H. F.; Zeng, G. F.; Ci, L.; Xiong, S. L.; Feng, J. K.; Qian, Y. T. Green, scalable, and controllable fabrication of nanoporous silicon from commercial alloy precursors for high-energy lithium-ion batteries. ACS Nano 2018, 12, 4993–5002.

Li, Y. Z.; Yan, K.; Lee, H. W.; Lu, Z. D.; Liu, N.; Cui, Y. Growth of conformal graphene cages on micrometre-sized silicon particles as stable battery anodes. Nat. Energy 2016, 1, 15029.

Wu, H.; Cui, Y. Designing nanostructured Si anodes for high energy lithium ion batteries. Nano Today 2012, 7, 414–429.

Li, J. Y.; Li, G.; Zhang, J.; Yin, Y. X.; Yue, F. S.; Xu, Q.; Guo, Y. G. Rational design of robust Si/C microspheres for high-tap-density anode materials. ACS Appl. Mater. Interfaces 2019, 11, 4057–4064.

Zhu, G. J.; Chao, D. L.; Xu, W. L.; Wu, M. H.; Zhang, H. J. Microscale silicon-based anodes: Fundamental understanding and industrial prospects for practical high-energy lithium-ion batteries. ACS Nano 2021, 15, 15567–15593.

Chen, F. Q.; Han, J. W.; Kong, D. B.; Yuan, Y. F.; Xiao, J.; Wu, S. C.; Tang, D. M.; Deng, Y. Q.; Lv, W.; Lu, J. et al. 1000 Wh·L−1 lithium-ion batteries enabled by crosslink-shrunk tough carbon encapsulated silicon microparticle anodes. Natl. Sci. Rev. 2021, 8, nwab012.

Kim, H.; Seo, M.; Park, M. H.; Cho, J. A critical size of silicon nano-anodes for lithium rechargeable batteries. Angew. Chem., Int. Ed. 2010, 49, 2146–2149.

Kasavajjula, U.; Wang, C. S.; Appleby, A. J. Nano- and bulk-silicon-based insertion anodes for lithium-ion secondary cells. J. Power Sources 2007, 163, 1003–1039.

Ge, M. Y.; Rong, J. P.; Fang, X.; Zhou, C. W. Porous doped silicon nanowires for lithium ion battery anode with long cycle life. Nano Lett. 2012, 12, 2318–2323.

Wang, W.; Kumta, P. N. Nanostructured hybrid silicon/carbon nanotube heterostructures: Reversible high-capacity lithium-ion anodes. ACS Nano 2010, 4, 2233–2241.

Yao, Y.; McDowell, M. T.; Ryu, I.; Wu, H.; Liu, N.; Hu, L. B.; Nix, W. D.; Cui, Y. Interconnected silicon hollow nanospheres for lithiumion battery anodes with long cycle life. Nano Lett. 2011, 11, 2949–2954.

Mu, T. S.; Zhao, Y.; Zhao, C. T.; Holmes, N. G.; Lou, S. F.; Li, J. J.; Li, W. H.; He, M. X.; Sun, Y. P.; Du, C. Y. et al. Stable silicon anodes by molecular layer deposited artificial zincone coatings. Adv. Funct. Mater. 2021, 31, 2010526.

He, T.; Feng, J. R.; Zhang, Y.; Zu, L. H.; Wang, G. C.; Yu, Y.; Yang, J. H. Stress-relieved nanowires by silicon substitution for high-capacity and stable lithium storage. Adv. Energy Mater. 2018, 8, 1702805.

Li, X. L.; Yan, P. F.; Xiao, X. C.; Woo, J. H.; Wang, C. M.; Liu, J.; Zhang, J. G. Design of porous Si/C-graphite electrodes with long cycle stability and controlled swelling. Energy Environ. Sci. 2017, 10, 1427–1434.

Zhou, X. M.; Liu, Y.; Ren, Y.; Mu, T. S.; Yin, X. C.; Du, C. Y.; Huo, H.; Cheng, X. Q.; Zuo, P. J.; Yin, G. P. Engineering molecular polymerization for template-free SiOx/C hollow spheres as ultrastable anodes in lithium-ion batteries. Adv. Funct. Mater. 2021, 31, 2101145.

Liu, Z. G.; Lu, D. Z.; Wang, W.; Yue, L. G.; Zhu, J. L.; Zhao, L. G.; Zheng, H.; Wang, J. B.; Li, Y. Y. Integrating dually encapsulated Si architecture and dense structural engineering for ultrahigh volumetric and areal capacity of lithium storage. ACS Nano 2022, 16, 4642–4653.

Li, P.; Hwang, J. Y.; Sun, Y. K. Nano/microstructured silicongraphite composite anode for high-energy-density Li-ion battery. ACS Nano 2019, 13, 2624–2633.

Chen, Z.; Wang, C.; Lopez, J.; Lu, Z. D.; Cui, Y.; Bao, Z. N. High-areal-capacity silicon electrodes with low-cost silicon particles based on spatial control of self-healing binder. Adv. Energy Mater. 2015, 5, 1401826.

Kuang, Y. D.; Chen, C. J.; Kirsch, D.; Hu, L. B. Thick electrode batteries: Principles, opportunities, and challenges. Adv. Energy Mater. 2019, 9, 1901457.

Sun, C.; Liu, S. R.; Shi, X. L.; Lai, C.; Liang, J. J.; Chen, Y. S. 3D printing nanocomposite gel-based thick electrode enabling both high areal capacity and rate performance for lithium-ion battery. Chem. Eng. J. 2020, 381, 122641.

Wang, J. W.; Sun, Q.; Gao, X. J.; Wang, C. H.; Li, W. H.; Holness, F. B.; Zheng, M.; Li, R. Y.; Price, A. D.; Sun, X. H. et al. Toward high areal energy and power density electrode for Li-ion batteries via optimized 3D printing approach. ACS Appl. Mater. Interfaces 2018, 10, 39794–39801.

Zhou, L.; Ning, W. W.; Wu, C.; Zhang, D.; Wei, W. F.; Ma, J. M.; Li, C. C.; Chen, L. B. 3D-printed microelectrodes with a developed conductive network and hierarchical pores toward high areal capacity for microbatteries. Adv. Mater. Technol. 2019, 4, 1800402.

Tian, X. C.; Wang, T.; Ma, H.; Tang, K.; Hou, S. E.; Jin, H. Y.; Cao, G. Z. A universal strategy towards 3D printable nanomaterial inks for superior cellular high-loading battery electrodes. J. Mater. Chem. A 2021, 9, 16086–16092.

Aghajamali, M.; Xie, H. Z.; Javadi, M.; Kalisvaart, W. P.; Buriak, J. M.; Veinot, J. G. C. Size and surface effects of silicon nanocrystals in graphene aerogel composite anodes for lithium ion batteries. Chem. Mater. 2018, 30, 7782–7792.

Naficy, S.; Jalili, R.; Aboutalebi, S. H.; Gorkin III, R. A.; Konstantinov, K.; Innis, P. C.; Spinks, G. M.; Poulin, P.; Wallace, G. G. Graphene oxide dispersions: Tuning rheology to enable fabrication. Mater. Horiz. 2014, 1, 326–331.

Yao, B.; Chandrasekaran, S.; Zhang, J.; Xiao, W.; Qian, F.; Zhu, C.; Duoss, E. B.; Spadaccini, C. M.; Worsley, M. A.; Li, Y. Efficient 3D printed pseudocapacitive electrodes with ultrahigh MnO2 loading. Joule 2019, 3, 459–470.

Chan, C. L. C.; Lei, I. M.; Van De Kerkhof, G. T.; Parker, R. M.; Richards, K. D.; Evans, R. C.; Huang, Y. Y. S.; Vignolini, S. 3D printing of liquid crystalline hydroxypropyl cellulose-toward tunable and sustainable volumetric photonic structures. Adv. Funct. Mater. 2022, 32, 2108566.

Sun, K.; Wei, T. S.; Ahn, B. Y.; Seo, J. Y.; Dillon, S. J.; Lewis, J. A. 3D printing of interdigitated Li-ion microbattery architectures. Adv. Mater. 2013, 25, 4539–4543.

Zhu, C.; Han, T. Y. J.; Duoss, E. B.; Golobic, A. M.; Kuntz, J. D.; Spadaccini, C. M.; Worsley, M. A. Highly compressible 3D periodic graphene aerogel microlattices. Nat. Commun. 2015, 6, 6962.

Smay, J. E.; Cesarano, J.; Lewis, J. A. Colloidal inks for directed assembly of 3-D periodic structures. Langmuir 2002, 18, 5429–5437.

Tagliaferri, S.; Panagiotopoulos, A.; Mattevi, C. Direct ink writing of energy materials. Mater. Adv. 2021, 2, 540–563.

Ding, J. H.; Ur Rahman, O.; Zhao, H. R.; Peng, W. J.; Dou, H. M.; Chen, H.; Yu, H. B. Hydroxylated graphene-based flexible carbon film with ultrahigh electrical and thermal conductivity. Nanotechnology 2017, 28, 39LT01.

Li, X. L.; Gu, M.; Hu, S. Y.; Kennard, R.; Yan, P. F.; Chen, X. L.; Wang, C. M.; Sailor, M. J.; Zhang, J. G.; Liu, J. Mesoporous silicon sponge as an anti-pulverization structure for high-performance lithium-ion battery anodes. Nat. Commun. 2014, 5, 4105.

Shang, H.; Zuo, Z. C.; Yu, L.; Wang, F.; He, F.; Li, Y. L. Low-temperature growth of all-carbon graphdiyne on a silicon anode for high-performance lithium-ion batteries. Adv. Mater. 2018, 30, 1801459.

Gao, R. S.; Tang, J.; Zhang, K.; Ozawa, K.; Qin, L. C. A sandwichlike silicon-carbon composite prepared by surface-polymerization for rapid lithium-ion storage. Nano Energy 2020, 78, 105341.

Ren, W. F.; Wang, Y. H.; Zhang, Z. L.; Tan, Q. Q.; Zhong, Z. Y.; Su, F. B. Carbon-coated porous silicon composites as high performance Li-ion battery anode materials: Can the production process be cheaper and greener? J. Mater. Chem. A 2016, 4, 552–560.

Lu, S. J.; Wang, Z. T.; Zhang, X. H.; He, Z. J.; Tong, H.; Li, Y. J.; Zheng, J. C. In situ-formed hollow cobalt sulfide wrapped by reduced graphene oxide as an anode for high-performance lithiumion batteries. ACS Appl. Mater. Interfaces 2020, 12, 2671–2678.

Yang, X. M.; Rogach, A. L. Electrochemical techniques in battery research: A tutorial for nonelectrochemists. Adv. Energy Mater. 2019, 9, 1900747.

Wang, F.; Wang, B.; Ruan, T. T.; Gao, T. T.; Song, R. S.; Jin, F.; Zhou, Y.; Wang, D. L.; Liu, H. K.; Dou, S. X. Construction of structure-tunable Si@void@C anode materials for lithium-ion batteries through controlling the growth kinetics of resin. ACS Nano 2019, 13, 12219–12229.

Kaspar, J.; Graczyk-Zajac, M.; Riedel, R. Determination of the chemical diffusion coefficient of Li-ions in carbon-rich silicon oxycarbide anodes by electro-analytical methods. Electrochim. Acta 2014, 115, 665–670.

Acknowledgements

We gratefully acknowledge financial support from the National Natural Science Foundation of China (No. 52202371), the Natural Science Foundation of Shandong Province (No. ZR2020QE066), Opening Project of State Key Laboratory of Advanced Technology for Float Glass (No. 2020KF08), and SDUT&Zibo City Integration Development Project (No. 2021SNPT0045).

Author information

Authors and Affiliations

Corresponding authors

Electronic Supplementary Material

12274_2023_6113_MOESM1_ESM.pdf

3D printed silicon-based micro-lattices with ultrahigh areal/gravimetric capacities and robust structural stability for lithium-ion batteries

Rights and permissions

About this article

Cite this article

Fu, J., Wang, D., Li, Y. et al. 3D printed silicon-based micro-lattices with ultrahigh areal/gravimetric capacities and robust structural stability for lithium-ion batteries. Nano Res. 17, 2693–2703 (2024). https://doi.org/10.1007/s12274-023-6113-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-023-6113-0