Abstract

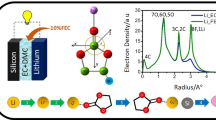

The cycling performance of silicon-carbon anodes in the electrolyte with different content (0, 2, 5, 10 wt%) fluorinated ethylene carbonate (FEC) was studied. Among all the electrolytes the injection of 2 wt% FEC into carbonate electrolyte, the retention capacity of silicon carbon anode enhanced from 54.81 to 83.82% after 50 cycles. The performance of SEI layer on the anode was characterized by SEM, EIS, FTIR, and XPS analysis. These studies reveal that the SEI layer formed in the FEC-containing electrolyte effectively reduced the capacity loss of the material and reduced the interfacial impedance.

Similar content being viewed by others

References

Chen Y, Nie M, Lucht BL, Saha A, Guduru PR, Bose A (2014) High capacity, stable silicon/carbon anodes for lithium-ion batteries prepared using emulsion-templated directed assembly. ACS Appl Mater Interfaces 6:4678–4683

Zhou R, Fan RJ, Tian ZY, Zhou Y, Guo HJ, Kou L, Zhang DP (2016) Preparation and characterization of core–shell structure Si/C composite with multiple carbon phases as anode materials for lithium ion batteries. J Alloys Compd 658:91–97

Zhou Y, Guo H, Yong Y, Wang Z, Li X, Zhou R (2017) Introducing reduced graphene oxide to improve the electrochemical performance of silicon-based materials encapsulated by carbonized polydopamine layer for lithium ion batteries. Mater Lett 195:164–167

Cui LF, Ruffo R, Chan CK, Peng HL, Cui Y (2009) Crystalline-amorphous core-shell silicon nanowires for high capacity and high current battery electrodes. Nano Lett 9:491–495

Li XL, Meduri P, Chen XL, Qi W, Engelhard MH, Xu W, Ding F, Xiao J, Wang W, Wang CM, Zhang JG, Liu J (2012) Hollow core-shell structured porous Si-C nanocomposites for Li-ion battery anodes. J Mater Chem 22:11014–11017

Cho J (2010) Porous Si anode materials for lithium rechargeable batteries. J Mater Chem 20:4009–4014

Park MS, Wang GX, Liu HK, Dou SX (2006) Electrochemical properties of Si thin film prepared by pulsed laser deposition for lithium ion micro-batteries. Electrochim Acta 51:5246–5249

Wu Y, Cui Y, Huynh L, Barrelet CJ, Bell DC, Lieber CM (2004) Controlled growth and structures of molecular-scale silicon nanowires. Nano Lett 4:433–436

Zhu H, Yang K, Lan H, Qian S, Yu H, Yan L, Long N, Shui M, Shu J (2017) Electrochemical kinetics of Na2Ti3O7 as anode material for lithium-ion batteries. J Electroanal Chem 788:203–209

Shu J, Li H, Yang RZ, Shi Y, Huang XJ (2006) Cage-like carbon nanotubes/Si composite as anode material for lithium ion batteries. Electrochem Commun 8:51–54

Shu J, Shui M, Xu D, Gao S, Yi TF, Wang DJ, Li X, Ren YL (2011) Design and comparison of ex situ and in situ devices for Raman characterization of lithium titanate anode material. Ionics 17:503–509

Yan L, Qian SS, Yu HX, Li P, Lan H, Long NB, Zhang RF, Shui M, Shu J (2017) Carbon-enhanced electrochemical performance for spinel Li5Cr7Ti6O25 as a lithium host material. ACS Sustain Chem Eng 5:957–964

Yu H, Luo M, Qian S, Yan L, Li P, Lan H, Long N, Shui M, Shu J (2017) Ba0.9La0.1Li2Ti6O14: Advanced lithium storage material for lithium-ion batteries. Electrochim Acta 232:132–141

Yang J, Wang BF, Wang K, Liu Y, Xie JY, Wen ZS (2003) Si/C composites for high capacity lithium storage materials. Electrochem Solid State Lett 6:A154–A156

Lee HY, Lee SM (2004) Carbon-coated nano-Si dispersed oxides/graphite composites as anode material for lithium ion batteries. Electrochem Commun 6:465–469

Zhang SS (2006) A review on electrolyte additives for lithium-ion batteries. J Power Sources 162:1379–1394

Xu MQ, Zhou L, Hao LS, Xing LD, Li WS, Lucht BL (2011) Investigation and application of lithium difluoro(oxalate)borate (LiDFOB) as additive to improve the thermal stability of electrolyte for lithium-ion batteries. J Power Sources 196:6794–6801

Wang J, Liu Z, Yan G, Li H, Peng W, Li X, Song L, Shih K (2016) Improving the electrochemical performance of lithium vanadium fluorophosphate cathode material: focus on interfacial stability. J Power Sources 329:553–557

Liu YJ, Lv J, Fei Y, Huo XD, Zhu YZ (2013) Improvement of storage performance of LiMn2O4/graphite battery with AlF3-coated LiMn2O4. Ionics 19:1241–1246

Wang J, Zhang Q, Li X, Xu D, Wang Z, Guo H, Zhang K (2014) Three-dimensional hierarchical Co3O4/CuO nanowire heterostructure arrays on nickel foam for high-performance lithium ion batteries. Nano Energy 6:19–26

Liu ZM, Peng WJ, Shih KM, Wang JX, Wang ZX, Guo HJ, Yan GC, Li XH, Song LB (2016) A MoS2 coating strategy to improve the comprehensive electrochemical performance of LiVPO4F. J Power Sources 315:294–301

Nakajima T (2007) Surface structures and electrochemical characteristics of surface-modified carbon anodes for lithium ion battery. Solid State Sci 9:777–784

Wang RH, Li XH, Wang ZX, Guo HJ, Hou T, Yan GC, Huang B (2015) Lithium carbonate as an electrolyte additive for enhancing the high-temperature performance of lithium manganese oxide spinel cathode. J Alloys Compd 618:349–356

Wang RH, Li XH, Wang ZX, Guo HJ, Wang JX, Hou T (2015) Impacts of vinyl ethylene carbonate and vinylene carbonate on lithium manganese oxide spinel cathode at elevated temperature. J Alloys Compd 632:435–444

Park MH, Lee YS, Lee H, Han Y-K (2011) Low Li+ binding affinity: an important characteristic for additives to form solid electrolyte interphases in Li-ion batteries. J Power Sources 196:5109–5114

Xu C, Lindgren F, Philippe B, Gorgoi M, Bjorefors F, Edstrom K, Gustafsson T (2015) Improved performance of the silicon anode for Li-ion batteries: understanding the surface modification mechanism of fluoroethylene carbonate as an effective electrolyte additive. Chem Mater 27:2591–2599

Jm MDLH, Balbuena PB (2014) Reduction mechanisms of additives on Si anodes of Li-ion batteries. Phys Chem Chem Phys 16:17091–17098

Michan AL, Parirnalam BS, Leskes M, Kerber RN, Yoon T, Grey CP, Lucht BL (2016) Fluoroethylene carbonate and vinylene carbonate reduction: understanding lithium-ion battery electrolyte additives and solid electrolyte interphase formation. Chem Mater 28:8149–8159

Shkrob IA, Wishart JF, Abraham DP (2015) What makes fluoroethylene carbonate different?. J Phys Chem C 119:14954–14964

Nie M, Abraham DP, Chen Y, Bose A, Lucht BL (2013) Silicon solid electrolyte interphase (SEI) of lithium ion battery characterized by microscopy and spectroscopy. J Phys Chem C 117:13403–13412

Dalavi S, Guduru P, Lucht BL (2012) Performance enhancing electrolyte additives for lithium ion batteries with silicon anodes. J Electrochem Soc 159:A642–A646

Xu K (2004) Nonaqueous liquid electrolytes for lithium-based rechargeable batteries. Chem Rev 104:4303–4417

Yan G, Li X, Wang Z, Guo H, Wang J (2014) Compatibility of graphite with 1,3-(1,1,2,2-Tetrafluoroethoxy)propane and fluoroethylene carbonate as cosolvents for nonaqueous electrolyte in lithium-ion batteries. J Phys Chem C 118:6586–6593

Yan G, Li X, Wang Z, Guo H, Xiong X (2014) Beneficial effects of 1-propylphosphonic acid cyclic anhydride as an electrolyte additive on the electrochemical properties of LiNi0.5Mn1.5O4 cathode material. J Power Sources 263:231–238

Cao R, Zhuang Q-C, Tian L-L, Qiu X-Y, Shi Y-L (2014) Electrochemical impedance spectroscopic study of the lithium storage mechanism in commercial molybdenum disulfide. Ionics 20:459–469

Wang G, Zhang R, Jiang T, Chernova NA, Dong Z, Whittingham MS (2014) Facile synthesis and electrochemical performance of the nanoscaled FePy anode. J Power Sources 270:248–256

Chen L, Wang K, Xie X, Xie J (2007) Effect of vinylene carbonate (VC) as electrolyte additive on electrochemical performance of Si film anode for lithium ion batteries. J Power Sources 174:538–543

Etacheri V, Haik O, Goffer Y, Roberts GA, Stefan IC, Fasching R, Aurbach D (2012) Effect of fluoroethylene carbonate (FEC) on the performance and surface chemistry of Si-nanowire Li-ion battery anodes. Langmuir 28:965–976

Lu H, Wu L, Xiao L, Ai X, Yang H, Cao Y (2016) Investigation of the effect of fluoroethylene carbonate additive on electrochemical performance of Sb-based anode for sodium-ion batteries. Electrochim Acta 190:402–408

Gao D-M, Zhao D-L, Hu J-B, Li Q-L (2008) Preparation of a novel COOH ion implantation sensor and its application. Chin J Chem 26:130–133

Wang RH, Li XH, Wang ZX, Guo HJ, He ZJ (2015) Electrochemical analysis for enhancing interface layer of spinel Li4Ti5O12: p-Toluenesulfonyl isocyanate as electrolyte additive. ACS Appl Mater Interfaces 7:23605–23614

Wang R, Li X, Wang Z, Zhang H (2017) Electrochemical analysis graphite/electrolyte interface in lithium-ion batteries: p-Toluenesulfonyl isocyanate as electrolyte additive. Nano Energy 34:131–140

Acknowledgments

This work was sponsored by the Science and Technology research on strategic emerging industry of Hunan Province, China (Grant No. 2016GK4029).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tang, WJ., Peng, WJ., Yan, GC. et al. Effect of fluoroethylene carbonate as an electrolyte additive on the cycle performance of silicon-carbon composite anode in lithium-ion battery. Ionics 23, 3281–3288 (2017). https://doi.org/10.1007/s11581-017-2143-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-017-2143-5