Abstract

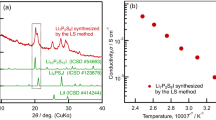

Micro-ferrotitanium powders have been prepared by molten salt electrolysis via directly electrochemical reduction of solid ilmenite in eutectic CaCl2-NaCl melt at 973 K. In the direct electrochemical reduction process, the reduction of FeTiO3 first gives rise to the formation of Fe and CaTiO3, which as intermediates will be further deoxidized at the interface of iron metals, solid CaTiO3 matrix, and electrolyte to directly form ferrotitanium alloy powders in porous structure. Furthering the electrolytic time can promote the dense structure of ilmenite pellet turn to be more porous, indicating pores inside the pellet are sufficient for the diffusion of oxygen ions. Based on the reduction behavior of partially reduced powders in metallic cavity electrode during the cathodic potentiostatic electrolysis, it shows that the slow deoxidization rate is mainly caused by the more and more difficult reduction of CaTiO3 than that of FeTiO3.

Similar content being viewed by others

References

Tan S, Örs T, Aydinol MK, Öztürk T, Karakaya İ (2009) J Alloy Compd 475:368–372

Wang D, Jin X, Chen GZ (2008) Annu Rep Prog Chem Sect C 104:189–234

Zou X, Lu X, Zhou Z, Xiao W, Zhong Q, Li C, Ding W (2014) J Mater Chem A 2:7421–7430

Descallar-Arriesgado RF, Kobayashi N, Kikuchi T, Suzuki RO (2011) Electrochim Acta 56:8422–8429

Abdelkader AM, Kilby KT, Cox A, Fray DJ (2013) Chem Rev 113:2863–2886

Xiao W, Jin X, Deng Y, Wang D, Hu X, Chen GZ (2006) ChemPhysChem 7:1750–1758

Shi X, Jin X, Xiao W, Hou X, Chen H, Chen GZ (2011) Chem-Eur J 17:8562–8567

Xu Y, Jiang H, Li X, Xiao H, Xiao W, Wu T (2014) J Mater Chem A 2:13345–13351

Kai J, Hu X, Ma M, Dihua W, Guohong Q, Xianbo J, Chen GZ (2006) Angew Chem Int Edit 45:428–432

Chen GZ (2015) Miner Process Extr M 124:96–105

Fray DJ (2001) JOM 53:27–31

Liu X, Hu M, Bai C, Lv X (2014) High Temp Mater-Isr 33:377–383

Rong L, He R, Wang Z, Peng J, Jin X, Chen GZ (2014) Electrochim Acta 147:352–359

Hu M, Bai C, Liu X, Lv XI, Du J (2011) J Min Metall B 47:193–198

Li G, Jin X, Wang D, Chen GZ (2009) J Alloy Compd 482:320–327

Panigrahi M, Lizuka A, Shibata E, Nakamura T (2013) J Alloy Compd 550:545–552

Chen ZY, Chou KC, Li FS (2013) J Manufac Sci Pro 13:127–131

Panigrahi M, Shibata E, Lizuka A, Nakamura T (2013) Electrochim Acta 93:143–151

Castrillejo Y, Martínez AM, Haarberg GM, Børresen B, Osen KS, Tunold R (1997) Electrochim Acta 42:1489–1494

Yan XY, Fray DJ (2005) J Electrochem Soc 152:D12–D21

Xiao W, Jin X, Chen GZ (2013) J Mater Chem A 1:10243–10250

Wang T, Gao H, Jin X, Chen H, Peng J, Chen GZ (2011) Electrochem Commun 13:1492–1495

Wu T, Xiao W, Jin X, Liu C, Wang D, Chen GZ (2008) Phys Chem Chem Phys 10:1809–1818

Dring K, Dahswodd RD, Inman D (2005) J Electrochem Soc 152:E104–E113

Osarinmwian C, Roberts EPL, Mellor IM (2015) Chem Phys Lett 621:184–187

Wang D, Qiu G, Jin X, Hu X, Chen GZ (2006) Angew Chem Int Edit 45:2384–2388

Xiao W, Wang D (2014) Chem Soc Rev 43:3215–3228

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Project Nos. 51274108 and 21263007).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, Z., Hua, Y., Xu, C. et al. Synthesis of micro-FeTi powders by direct electrochemical reduction of ilmenite in CaCl2-NaCl molten salt. Ionics 23, 213–221 (2017). https://doi.org/10.1007/s11581-016-1810-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-016-1810-2