Abstract

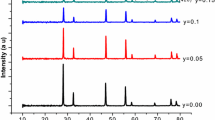

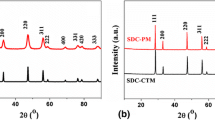

Samarium-doped Ceria powders for solid electrolyte ceramics were synthesized by a combustion process. Cerium nitrate and samarium nitrate were used as the starting materials, and glycine was used as fuel. Decomposition of unburned nitrogen and carbon residues was investigated by simultaneous thermogravimetry analysis and differential thermal analysis experiments. The X-ray diffraction results showed that the single-phase fluorite structure forms at a relatively low calcination temperature of 800 °C. X-rays patterns of the SDC powders revealed that the crystallite size of the powders increases with increasing calcination temperature. The sintering behavior results showed that more than 96% of the relative density is obtained for powders sintered at 1,100 °C for 8 h. The alternating current impedance spectroscopy results showed that the SDC15 sample sintered at 1,100 °C has ionic conductivity of 0.015 Scm−1at 650 °C in air. The present work results have indicated that glycine–nitrate route is a relatively low-temperature preparation technique to synthesize SDC powders with a high sinterability and a good ionic conductivity.

Similar content being viewed by others

References

Will J, Mitterdorfer A, Keinlogel C, Perednis D, Gauckler IJ (2000) Solid State Ion 131:79

Huijsmans, JPP, Van Berkei FPF, Khristie GM (1998) J Power Sources 71:107

Yahiro H, Eguchi Y, Eguchi K, Arai H (1998) J Appl Electrochem 18:527

Steele BCH (2000) Solid State Ion 129:95

Yahiro H, Eguchi Y, Eguchi K, Arai H (1989) Solid State Ion 36:71

Huage W, Shuk P, Green Blatt M (1997) Solid State Ion 100:23

Chung DY, Lee EH (2004) J Alloys Compd 314:69

Li JG, Ikegami T, Mori T (2004) Acta Materialia 52:2221

Wang W, Inaba H, Tagawa H, Hashimoto T (1997) J Electrochem Soc 144:4077

Maffei N, Kuriakose AK (1998) Solid State Ion 107:67

Reiss I, Braunshtein D, Tannhause DS (1981) J Am Ceram Soc 64:479

Van Herle J, Horita T, Kawada T, Sakai N, Yokokawa H, Dokiya M (1996) Solid State Ion 86–88:1255

Hong SJ, Mehta K, Virkar AV (1998) J Electrochem Soc 145:638

Yamashita K, Ramanujachary KV, Greenblatt M (1995) Solid State Ion 81:53–60

Purohit RD, Sharma BP, Pillai KT, Tyagi AK (2001) Mater Res Bull 36:2711

Purohit RD, Sharma BP, Tyagi AK (2000) J Nucl Mater 288:51

Kingsley JJ, Suresh K, Patil KC (1990) J Mater Sci 25:1305

Purohit RD, Saha S, Tyagi AK (2006) Ceram Int 32:143

Shea LF, Mackittrick J, Lopez OA (1996) J Am Ceram Soc 79:3257

KudoT, Obayashi H (1975) J Electrochem Soc 122(1):142

Zha S, Xia C, Meng G (2003) J Power Sources 115:44

Eguchi K, Setoguchi T, Inoue T, Arai H (1992) Solid State Ion 52:165

Atsuta K, Civiello MD, Pacaid B, Seguelong T, Suda E (2002) In: Huijsmans J (ed) Proceedings of Fifth European Solid OFC Forum. ISBN 3905592-10-x, 1–5July

Torrens RS, Sammes NM, Tompsett GA (1998) Solid State Ion 111:479

Mori T, Wang Y, Drennan J, Auchterlonie G, Li JG, Ikegami T (2004) Solid State Ion 175:641

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, K., Acharya, S.A. & Bhoga, S.S. Low temperature processing of dense samarium-doped CeO2 ceramics: sintering and intermediate temperature ionic conductivity. Ionics 13, 429–434 (2007). https://doi.org/10.1007/s11581-007-0123-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-007-0123-x