Abstract

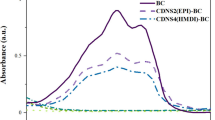

To overcome the intrinsic limitations of ergocalciferol, layer-by-layer oil-in-water emulsions were formulated and applied in the microencapsulation of ergocalciferol. The primary emulsions were prepared using rhamnolipids to stabilize oil droplets, and then the secondary emulsions were formed by electrostatic deposition of cationic chitosan onto anionic rhamnolipids-coated droplets. The effects of pH, ionic strength, and thermal treatment on the stability of emulsions were investigated. Secondary emulsions were more stable than primary emulsions at low pH and high NaCl concentrations. Both emulsions showed excellent physicochemical stability during long-term storage. The droplet size of emulsions remained stable, and the ergocalciferol retention in emulsions was still maintained at over 95% after 30 days of storage. These results indicate that the resistance of prepared emulsions to different environmental stresses is enhanced. Moreover, this study gives important information for extending the utilization of rhamnolipids and chitosan in the delivery system for functional ingredients.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

M. Guttoff, A.H. Saberi, D.J. McClements, Food Chem. 171, 117–122 (2015)

N. Khalid, I. Kobayashi, Z. Wang et al., RSC Adv. 5(118), 97151–97162 (2015)

M. Haham, S. Ish-Shalom, M. Nodelman et al., Food Funct. 3(7), 737–744 (2012)

M.F. Holick, Am. J. Clin. Nutr. 79(3), 362–371 (2004)

A. Cranney, H.A. Weiler, S. O’Donnell, L. Puil, Am. J. Clin. Nutr. 88(2), 513S-519S (2008)

S. Rooze, F. Mathieu, W. Claus, et al. Trop. Med. Int. Health 21(6), 768–775 (2016)

N. Walia, L. Chen, Food Chem. 305, 125475 (2020)

E.L. Bishop, A. Ismailova, S. Dimeloe, M. Hewison, J.H. White, JBMR plus 5(1), e10405 (2021)

H. Pool, S. Mendoza, H. Xiao, D.J. McClements, Food Funct. 4(1), 162–174 (2013)

N. Khalid, G. Shu, B.J. Holland, I. Kobayashi, M. Nakajima, C.J. Barrow, Food Res. Int. 102, 364–371 (2017)

Z. Ma, N. Khalid, G. Shu et al., ACS Omega 4(6), 10502–10509 (2019)

Z. Ma, Y. Zhao, N. Khalid, et al. Food Hydrocolloids 108, 105977 (2020)

G. Shu, N. Khalid, Y. Zhao, M.A. Neves, I. Kobayashi, M. Nakajima, Food Res. Int. 90, 320–327 (2016)

G. Shu, N. Khalid, T.B. Tan et al., J. Funct. Foods 38, 28–35 (2017)

F. Liu, D. Wang, C. Sun, D.J. McClements, Y. Gao, Food Chem. 205, 129–139 (2016)

M. Noshad, M. Mohebbi, A. Koocheki, F. Shahidi, J. Dispersion Sci. Technol. 37(1), 56–65 (2016)

E. Dickinson, Soft Matter 4(5), 932–942 (2008)

C. Qiu, M. Zhao, D.J. McClements, Food Hydrocolloids 43, 377–387 (2015)

Y. Chang, D.J. McClements, Food Hydrocolloids 51, 252–260 (2015)

X. Xu, L. Luo, C. Liu, D.J. McClements, Food Hydrocolloids 64, 112–122 (2017)

R.B. Lovaglio, F.J. dos Santos, M.J. Junior, J. Contiero, Colloids Surf. B 85(2), 301–305 (2011)

Z. Li, L. Dai, D. Wang, L. Mao, Y. Gao, J. Agric. Food Chem. 66(15), 3922–3929 (2018)

L. Bai, D.J. McClements, J. Colloid Interface Sci. 479, 71–79 (2016)

L.A. Ehlen, T.A. Marshall, F. Qian, J.S. Wefel, J.J. Warren, Nutr. Res. 28(5), 299–303 (2008)

E. Alehosseini, S.M. Jafari, H.S. Tabarestani, Food Chem. 354, 129591 (2021)

G. Liu, M. Hu, X. Du et al., Food Hydrocolloids 124, 107309 (2022)

P. Lv, D. Wang, R. Liang et al., Lwt 151, 112122 (2021)

U. Klinkesorn, Food Rev. Intl. 29(4), 371–393 (2013)

G. Shu, N. Khalid, T.B. Tan et al., Int. J. Food Sci. Technol. 53(2), 430–440 (2018)

S. Ogawa, E.A. Decker, D.J. McClements, J. Agric. Food Chem. 52(11), 3595–3600 (2004)

A.M. Chuah, T. Kuroiwa, I. Kobayashi, M. Nakajima, Food Hydrocolloids 23(3), 600–610 (2009)

X.-Y. Wang, M.-C. Heuzey, Langmuir 32(4), 929–936 (2016)

X.-Y. Wang, J. Wang, D. Rousseau, C.-H. Tang, Food Hydrocolloids 105, 105811 (2020)

D. Guzey, D.J. McClements, Adv. Coll. Interface. Sci. 128, 227–248 (2006)

D. Güzey, D.J. McClements, Food Biophys. 1(1), 30–40 (2006)

S.A. Onaizi, Sep. Purif. Technol. 259, 118060 (2021)

Acknowledgements

This work was supported by the Start-up Program of Shanghai Jiao Tong University (No. 19X100040087).

Author information

Authors and Affiliations

Contributions

Zhaoxiang Ma: Investigation, Data curation, Methodology, Writing—Original draft; Cuixia Sun: Validation, Data curation; Zhang Chen: Writing—Review & Editing, Visualization, Conceptualization; Yiguo Zhao: Supervision, Conceptualization, Funding acquisition, Writing—Review & Editing.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare no competing interests.

Ethical Approval

Not applicable, because this paper does not contain any studies with human or animal subjects.

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ma, Z., Sun, C., Chen, Z. et al. Fabrication and Characteristic of Rhamnolipid-chitosan Coated Emulsions for Loading Ergocalciferol. Food Biophysics 18, 228–239 (2023). https://doi.org/10.1007/s11483-022-09768-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-022-09768-1