Abstract

Weathered rockfill materials, characterized by a mixture of soil matrix and rock aggregates, are widely distributed in mountainous areas. These soils are frequently used for subgrade or riprap in engineering practice, and the mobilized shear strength is crucial for analyzing the displacement and stability of these geo-structures. A series of direct shear tests are performed on a gap-graded soil with a full range of coarse fraction. The behavior of gap-graded soils is analyzed, and a simple model is proposed for the evolution of mobilized stress ratio during direct shearing process based on mixture theory. The change of inter-aggregate configuration is incorporated by introducing a structure variable which increases with coarse fraction and decreases approximately linearly with the overall horizontal shear strain in double logarithmic plot. It reasonably reflects a gradually transformation from a matrix-sustained structure into an aggregate-sustained one with the increase of coarse fraction. The model has four parameters, and at least two direct shear tests need to be done for the calibration. Validation of the model is done by using the test data in this work and those from the literature.

Similar content being viewed by others

Abbreviations

- a, b :

-

Model parameters for the fine matrix

- \( C_{\text{u}} \) :

-

Coefficient of uniformity

- \( C_{\text{c}} \) :

-

Coefficient of curvature

- D 50 :

-

Diameters at 50 percentiles in PSD curve

- e :

-

Overall void ratio

- e a :

-

Void ratio of coarse aggregates

- e m :

-

Void ratio of fines

- e min :

-

Overall minimum void ratio

- \( e_{{\hbox{min} ,{\text{a}}}} \) :

-

Minimum void ratio of coarse aggregates

- \( e_{{\hbox{max} ,{\text{a}}}} \) :

-

Maximum void ratio of coarse aggregates

- \( m_{s} \) :

-

Dry mass of fine matrix

- \( m_{\text{a}} \) :

-

Dry mass of coarse aggregates

- V a :

-

Volume of coarse aggregates

- V sm :

-

Volume of solid phase in fine matrix

- V vm :

-

Volume of void phase in fine matrix

- α, β :

-

Structure variables

- ε h :

-

Overall horizontal shear strain

- ε h,m :

-

Horizontal shear strain of matrix

- ε v :

-

Overall vertical strain

- η :

-

Structure variable

- μ σ :

-

Overall mobilized stress ratio

- μ σ,m :

-

Mobilized stress ratio of matrix

- ξ 1, ξ 2 :

-

Structure parameters

- ρ a :

-

Density of aggregates

- ρ s :

-

Density of fine particles

- \( \sigma^{\prime} \) :

-

Overall vertical stress

- \( \sigma^{\prime}_{\text{m}} \) :

-

Vertical stress of matrix

- τ :

-

Overall shear stress

- τ m :

-

Shear stress of matrix

- \( \phi_{\text{a}} \) :

-

Volume fraction of coarse aggregates

- \( \overline{\phi }_{\text{a}} \) :

-

The maximum packing density of coarse aggregates

- ψ a :

-

Coarse fraction

References

Bolton MD, Lam SY, Osman AS (2009) Supporting excavations in clay-From analysis to decision-making. In: Geotechnical aspects of underground construction in soft ground-proceedings of the 6th international symposium, Shanghai, 1 December 2009, pp 15–28

Bolton MD, Powrie W, Symons IF (1990) The design of stiff in situ walls retaining over-consolidated clay part 1, short term behavior. Ground Eng 23(1):34–39

Bolton MD, Powrie W, Symons IF (1990) The design of stiff in situ walls retaining over-consolidated clay part 2, short term behavior. Ground Eng 23(2):22–28

Borana L, Yin JH, Singh DN, Shukla SK (2016) Interface behavior from suction-controlled direct shear test on completely decomposed granitic soil and steel surfaces. Int J Geomech 16(6):D4016008

Chang CS, Meidani M, Deng Y (2017) A compression model for sand-silt mixtures based on the concept of active and inactive voids. Acta Geotech 12(6):1301–1317

Chang CS, Yin ZY (2011) Micromechanical modeling for behavior of silty sand with influence of fine content. Int J Solids Struct 48(19):2655–2667

Chang WJ, Chang CW, Zeng JK (2014) Liquefaction characteristics of gap-graded gravelly soils in K0 condition. Soil Dyn Earthq Eng 56:74–85

Chandler RJ (2000) The third glossop lecture: clay sediments in depositional basins: the geotechnical cycle. Quart J Eng Geol Hydrogeol 33(1):7–39

Chen WB, Feng WQ, Yin JH, Chen JM, Borana L, Chen RP (2020) New model for predicting permanent strain of granular materials in embankment subjected to low cyclic loadings. J Geotech Geoenviron Eng 146(9):04020084

Chen WB, Liu K, Feng WQ, Borana L, Yin JH (2020) Influence of matric suction on nonlinear time-dependent compression behavior of a granular fill material. Acta Geotech 15(3):615–633

Chen WB, Liu K, Yin ZY, Yin JH (2020) Crushing and flooding effects on one-dimensional time-dependent behaviors of a granular soil. Int J Geomech 20(2):04019156

Chong SH, Santamarina JC (2016) Soil compressibility models for a wide stress range. J Geotech Geoenviron Eng 142(6):06016003

Cui YF, Zhou X, Guo CX (2017) Experimental study on the moving characteristics of fine grains in wide grading unconsolidated soil under heavy rainfall. J Mt Sci 14(3):417–431

De Boer R (2006) Trends in continuum mechanics of porous media, vol 18. Springer, New York

De Boer R, Ehlers W (1986) On the problem of fluid and gas-filled elasto-plastic solids. Int J Solids Struct 22(11):1231–1242

Duncan JM, Chang CY (1970) Nonlinear analysis of stress and strain in soils. J Soil Mech Found Div 96:1629–1653

Goudarzy M, König D, Schanz T (2016) Small strain stiffness of granular materials containing fines. Soils Found 56(5):756–764

Guo CX, Cui YF (2020) Pore structure characteristics of debris flow source material in the Wenchuan earthquake area. Eng Geol 267:105499

Herle I, Gudehus G (1999) Determination of parameters of a hypoplastic constitutive model from properties of grain assemblies. Mech Cohesive Frict Mater 4(5):461–486

Hong Z, Zeng LL, Cui YJ, Cai YQ, Lin C (2012) Compression behaviour of natural and reconstituted clays. Géotechnique 62(4):291–301

Jafari MK, Shafiee A (2004) Mechanical behavior of compacted composite clays. Can Geotech J 41(6):1152–1167

Kumar GV, Wood DM (1999) Fall cone and compression tests on clay ± gravel mixtures. Géotechnique 49(6):727–739

Li Y, Huang R, Chan LS, Chen J (2013) Effects of particle shape on shear strength of clay-gravel mixture. KSCE J Civil Eng 17(4):712–717

Lielens G, Pirotte P, Couniot A, Dupret F, Keunings R (1998) Prediction of thermo-mechanical properties for compression moulded composites. Compos Part A Appl Sci Manuf 29(1–2):63–70

McDowell GR (2002) On the yielding and plastic compression of sand. Soils Found 42(1):139–145

Mcdowell GR, Harireche O (2002) Discrete element modelling of yielding and normal compression of sand. Géotechnique 52(4): 299–304

Meng QX, Wang HL, Xu WY et al (2019) Multiscale strength reduction method for heterogeneous slope using hierarchical FEM/DEM modeling. Comput Geotech 115:103164

Mesri G, Vardhanabhuti B (2009) Compression of granular materials. Can Geotech J 46(4):369–392

Monkul MM, Ozden G (2007) Compressional behavior of clayey sand and transition fines content. Eng Geol 89(3):195–205

Nagula SS, Robinson RG, Krishnan JM (2018) Mechanical characterization of pavement granular materials using hardening soil model. Int J Geomech 18(12):04018157

Osman AS, Bolton MD (2004) A new design method for retaining walls in clay. Can Geotech J 41(3):451–466

Osman AS, Bolton MD (2006) Design of braced excavations to limit ground movements. Proc Inst Civil Eng Geotech Eng 159(3):167–175

Peng D, Xu Q, Liu F, He Y, Zhang S, Qi X, Zhang X (2018) Distribution and failure modes of the landslides in Heitai terrace, China. Eng Geol 236:97–110

Pestana JM, Whittle AJ (1995) Compression model for cohesionless soils. Géotechnique 45(4):611–631

Peters JF, Berney ES IV (2010) Percolation threshold of sand-clay binary mixtures. J Geotech Geoenviron Eng 136(2):310–318

Qin CB, Chian SC (2017) Kinematic analysis of seismic slope stability with a discretisation technique and pseudo-dynamic approach: a new perspective. Géotechnique 68(6):492–503

Ruggeri P, Segato D, Fruzzetti VME, Scarpelli G (2016) Evaluating the shear strength of a natural heterogeneous soil using reconstituted mixtures. Géotechnique 66(11):941–946

Shi XS, Gao YF, Ding JW (2021) Estimation of the compression behavior of sandy clay considering sand fraction effect based on equivalent void ratio concept. Eng Geol (in press)

Shi XS, Herle I (2017) Numerical simulation of lumpy soils using a hypoplastic model. Acta Geotech 12(2):349–363

Shi, XS, Liu, K, Yin, JH (2021) Effect of initial density, particle shape, and confining stress on the critical state behavior of weathered gap-graded granular soils. J Geotech Geoenviron Eng 147(2):04020160

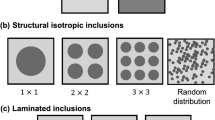

Shi XS, Nie J, Zhao J, Gao Y (2020) A homogenization equation for the small strain stiffness of gap-graded granular materials. Comput Geotech 121:103440

Shi XS, Yin J (2018) Consolidation behavior for saturated sand-marine clay mixtures considering the intergranular structure evolution. J Eng Mech 144(2):04017166

Shi XS, Zhao J, Yin J, Yu Z (2019) An elastoplastic model for gap-graded soils based on homogenization theory. Int J Solids Struct 163:1–14

Shin H, Santamarina JC (2012) Role of particle angularity on the mechanical behavior of granular mixtures. J Geotech Geoenviron Eng 139(2):353–355

Simoni A, Houlsby GT (2006) The direct shear strength and dilatancy of sand–gravel mixtures. Geotech Geol Eng 24(3):523

Tan DY, Yin JH, Feng WQ, Zhu ZH, Qin JQ, Chen WB (2019) New simple method for calculating impact force on flexible barrier considering partial muddy debris flow passing through. J Geotech Geoenviron Eng 145(9):04019051

Tandon GP, Weng GJ (1988) A theory of particle-reinforced plasticity. J Appl Mech 55(1):126–135

Thevanayagam S, Martin GR (2002) Liquefaction in silty soils-screening and remediation issues. Soil Dyn Earthq Eng 22(9–12):1035–1042

Thevanayagam S, Mohan S (2000) Intergranular state variables and stress-strain behaviour of silty sands. Géotechnique 50(1):1–23

Thevanayagam S, Shenthan T, Mohan S, Liang J (2002) Undrained fragility of clean sands, silty sands, and sandy silts. J Geotech Geoenviron Eng 128(10):849–859

Ueda T, Matsushima T, Yamada Y (2011) Effect of particle size ratio and volume fraction on shear strength of binary granular mixture. Granul Matter 13(6):731–742

Vallejo LE (2001) Interpretation of the limits in shear strength in binary granular mixtures. Can Geotech J 38(5):1097–1104

Vallejo LE, Lobo-Guerrero S, Seminsky LF (2014) Shear strength of sand-gravel mixtures: laboratory and theoretical analysis. In: Geo-congress 2014: geo-characterization and modeling for sustainability, pp 74–83

Vallejo LE, Mawby R (2000) Porosity influence on the shear strength of granular material-clay mixtures. Eng Geol 58(2):125–136

Wei HZ, Xu WJ, Xu XF, Meng QS, Wei CF (2018) Mechanical properties of strongly weathered rock-soil mixtures with different rock block contents. Int J Geomech 18(5):04018026

Xu DS, Tang JY, Zou Y, Rui R, Liu HB (2019) Macro and micro investigation of gravel content on simple shear behavior of sand-gravel mixture. Constr Build Mater 221:730–744

Yagiz S (2001) Brief note on the influence of shape and percentage of gravel on the shear strength of sand and gravel mixtures. Bull Eng Geol Env 60(4):321–323

Yang ZY, Juo JL (2001) Interpretation of sieve analysis data using the box-counting method for gravelly cobbles. Can Geotech J 38(6):1201–1212

Yao YP, Hou W, Zhou AN (2009) UH model: three-dimensional unified hardening model for overconsolidated clays. Géotechnique 59(5):451–469

Yao YP, Sun DA, Luo T (2004) A critical state model for sands dependent on stress and density. Int J Numer Anal Methods Geomech 28(4):323–337

Yin JH (1999) Non-linear creep of soils in oedometer tests. Géotechnique 49(5):699–707

Yin JH (1999) Properties and behavior of Hong Kong marine deposits with different clay contents. Can Geotech J 36(6):1085–1095

Yin ZY, Huang HW, Hicher PY (2016) Elastoplastic modeling of sand-silt mixtures. Soils Found 56(3):520–532

Yin ZY, Zhao J, Hicher PY (2014) A micromechanics-based model for sand-silt mixtures. Int J Solids Struct 51(6):1350–1363

Zhang X, Baudet BA (2013) Particle breakage in gap-graded soil. Geotech Lett 3(2):72–77

Zhang Z, Cui Y, Chan DH, Taslagyan KA (2018) DEM simulation of shear vibrational fluidization of granular material. Granular Matter 20(4):71

Zhao MH, Zou XJ, Zou PX (2007) Disintegration characteristics of red sandstone and its filling methods for highway roadbed and embankment. J Mater Civ Eng 19(5):404–410

Zhou W, Xu K, Ma G, Yang L, Chang X (2016) Effects of particle size ratio on the macro-and microscopic behaviors of binary mixtures at the maximum packing efficiency state. Granul Matter 18(4):81

Zhou WH, Garg A, Garg A (2016) Study of the volumetric water content based on density, suction and initial water content. Measurement 94:531–537

Acknowledgments

This study was partially supported by the National Natural Science Foundation of China (under Grant No. 51908193) and the Fundamental Research Funds for the Central Universities (Grant No. B200201050; B200204032). The work in this paper is also supported by three GRF projects (Grant No. 16201419; PolyU 152209/17E; PolyU 152179/18E), a Research Impact Fund (RIF) project (R5037-18), all from Research Grants Council (RGC) of Hong Kong Special Administrative Region Government (HKSARG) of China. The authors also acknowledge the financial supports from Research Institute for Sustainable Urban Development of The Hong Kong Polytechnic University, grants (BBAG, ZDBS, ZVNC), from The Hong Kong Polytechnic University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1

Appendix 1

There are two types of structure according to the coarse fraction, matrix-sustained structure, and aggregate-sustained structure. In this study, we deal with the matrix-sustained structure, and the structure of the fine matrix is relatively uniform without macro-voids (Fig. 3). Therefore, volume of voids in mixtures can be well represented by the volume of voids in fine matrix, and the overall deformation of gap-graded mixtures relies on the decrease of volume of voids in fines. The mixture can be divided into three parts: (1) the solid phase of fine matrix (denoted as Vsm), (2) the volume of voids in fine matrix (denoted as Vvm), and (3) the volume of coarse aggregates (denoted as Va). Suppose that the volume of solid phase of fine matrix is one unit (i.e., Vsm = 1). The volume of voids in fine matrix is

where em is the void ratio of fine matrix. From the definition of the void ratio of aggregates ea,

Hence, the coarse fraction and overall void ratio at the transitional point can be derived according to its definition:

The overall void ratio can be derived according to its definition:

The dry mass of the fines ms and aggregates ma is

Suppose that the density of fines and aggregates is the same, the coarse fraction is derived as:

The following equations can be derived from Eq. (19) and Eq. (21):

The volume fraction of aggregates is defined as:

Substituting Eq. (22) into Eq. (23), it gives:

Rights and permissions

About this article

Cite this article

Shi, X.S., Liu, K. & Yin, J. Analysis of mobilized stress ratio of gap-graded granular materials in direct shear state considering coarse fraction effect. Acta Geotech. 16, 1801–1814 (2021). https://doi.org/10.1007/s11440-020-01107-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-020-01107-3