Abstract

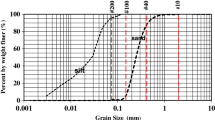

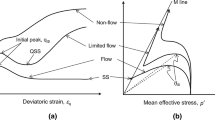

A compression model for sand–silt mixtures is needed in geotechnical engineering, for example in the analysis and prediction of deformation of levees and embankments due to internal erosion. In this paper, we introduce a novel concept of dividing the voids of a granular material into two hypothetical fractions: active and inactive voids. The active voids are kinematically available to the compression process. The inactive voids are kinematically unavailable to the compression process. The volume of active voids is dependent on the initial density and effective stress level. The volume of inactive voids is dependent on the amount of fines in the mixture. The current paper considers 1-D and isotropic compression behavior of sand–silt mixtures at stress levels lower than 2 MPa, so no substantial particle breakage is expected to occur. To successfully predict the void ratio for a sand–silt mixture during compression loading, we need (1) a mathematical expression for the evolution of the active void ratio during compression and (2) a relationship between the inactive void ratio and fines content of the mixture. For sand–silt mixtures with any amount of fines, the proposed model requires five material parameters, which are determined from two compression tests, and four minimum void ratio tests on sand–silt mixtures with different fines content. The performance of the proposed model is verified for six different types of sand–silt mixture with various fines contents, by comparing the predicted void ratios with the measured data from the experiments. The comparisons show a good agreement between the predictions and the measured data and prove the suitability of the proposed model for the prediction of compressibility of sand–silt mixtures with any amount of fines.

Similar content being viewed by others

References

Benahmed N, Nguyen TK, Hicher PY, Nicolas M (2015) An experimental investigation into the effects of low plastic fines content on the behaviour of sand/silt mixtures. Eur J Environ Civ Eng 19:109–128. doi:10.1080/19648189.2014.939304

Bowen RM (1976) Theory of mixtures, part I. Contin. Phys. III

Cabalar AF (2010) Applications of the oedometer, triaxial and resonant column tests to the study of micaceous sands. Eng Geol 112:21–28. doi:10.1016/j.enggeo.2010.01.004

Chang CS, Meidani M (2012) Deformation and failure of soils under erosion. NSF C Eng Res Innov Conf. doi:10.13140/RG.2.1.1964.1204

Chang CS, Meidani M (2013) Dominant grains network and behavior of sand–silt mixtures: stress–strain modeling. Int J Numer Anal Methods Geomech 37:2563–2589. doi:10.1002/nag.2152

Chang CS, Wang J-Y, Ge L (2015) Modeling of minimum void ratio for sand–silt mixtures. Eng Geol 196:293–304. doi:10.1016/j.enggeo.2015.07.015

Chang CS, Wang JY, Ge L (2016) Maximum and minimum void ratios for sand–silt mixtures. Eng Geol 211:7–18. doi:10.1016/j.enggeo.2016.06.022

Chen C, Zhang LM, Chang DS (2016) Stress–strain behavior of granular soils subjected to internal erosion. J Geotech Geoenviron Eng 142:6016014. doi:10.1061/(ASCE)GT.1943-5606.0001561

Choo H, Burns SE (2015) Shear wave velocity of granular mixtures of silica particles as a function of finer fraction, size ratios and void ratios. Granul Matter 17:567–578. doi:10.1007/s10035-015-0580-2

Coop MR, Atkinson JH (1993) The mechanics of cemented carbonate sands. Géotechnique 43:53–67. doi:10.1680/geot.1993.43.1.53

Dash HK, Sitharam TG (2011) Undrained monotonic response of sand–silt mixtures: effect of nonplastic fines. Geomech Geoengin 6:47–58. doi:10.1080/17486021003706796

Derkaoui M, Missoum H, Bendani K, Belhouari F (2016) Shear behavior of sand–silt mixtures: a laboratory investigation of coastal silty sand soils of Mostaganem. Mar Georesour Geotechnol 34:668–680. doi:10.1080/1064119X.2015.1070388

Georgiannou VN (2006) The undrained response of sands with additions of particles of various shapes and sizes. Géotechnique 56:639–649. doi:10.1680/geot.2006.56.9.639

Hicher PY (2013) Modelling the impact of particle removal on granular material behaviour. Geotechnique 63:118–128. doi:10.1680/geot.11.P.020

Huang Y-T, Huang A-B, Kuo Y-C, Tsai M-D (2004) A laboratory study on the undrained strength of a silty sand from Central Western Taiwan. Soil Dyn Earthq Eng 24:733–743. doi:10.1016/j.soildyn.2004.06.013

Jehring MM, Bareither CA (2016) Tailings composition effects on shear strength behavior of co-mixed mine waste rock and tailings. Acta Geotech 11:1147–1166. doi:10.1007/s11440-015-0429-1

Ke L, Takahashi A (2015) Drained monotonic responses of suffusional cohesionless soils. J Geotech Geoenviron Eng 141:1–8. doi:10.1061/(ASCE)GT.1943-5606.0001327

Ke L, Ouyang M, Horikoshi K, Takahashi A (2016) Soil deformation due to suffusion and its consequences on undrained behavior under various confining pressures. Jpn Geotech Soc Spec Publ 2:368–373. doi:10.3208/jgssp.JPN-083

Khalil T, Saiyouri N, Muresan B, Hicher P-Y (2013) Internal erosion of chemically reinforced granular materials: a mathematical modeling approach. Int J Numer Anal Methods Geomech 37:491–502. doi:10.1002/nag.1108

Konishi Y, Hyodo M, Ito S (2007) Compression and undrained shear characteristics of sand-fines mixtures with various plasticity. JSCE J Geotech Geoenviron Eng 63:1142–1152. doi:10.2208/jscejc.63.1142

Kuerbis R, Negussey D, Vaid YP (1988) Effect of gradation and fines content on the undrained response of sand. In: Hydraul. Fill Struct. Geotech. Spec. Pub. No. 21. ASCE, New York, pp 330–345

Lade PV, Yamamuro JA (1997) Effects of nonplastic fines on static liquefaction of sands. Can Geotech J 34:918–928. doi:10.1139/t97-052

Lashkari A (2016) Prediction of flow liquefaction instability of clean and silty sands. Acta Geotech 11:987–1014. doi:10.1007/s11440-015-0413-9

Manzari MT, Dafalias YF (1997) A critical state two-surface plasticity model for sands. Géotechnique 47:255–272. doi:10.1680/geot.1997.47.2.255

Meidani M, Chang CS, Deng Y (2017) On active and inactive voids and a compression model for granular soils. Eng Geol 222:156–167. doi:10.1016/j.enggeo.2017.03.006

Mohammadi A, Qadimi A (2015) A simple critical state approach to predicting the cyclic and monotonic response of sands with different fines contents using the equivalent intergranular void ratio. Acta Geotech 10:587–606. doi:10.1007/s11440-014-0318-z

Monkul MM, Yamamuro JA, Lade PV (2011) Failure, instability, and the second work increment in loose silty sand. Can Geotech J 48:943–955. doi:10.1139/t11-013

Muir Wood D, Maeda K, Nukudani E (2010) Modelling mechanical consequences of erosion. Géotechnique 60:447–457. doi:10.1680/geot.2010.60.6.447

Murthy TG, Loukidis D, Carraro JAH et al (2007) Undrained monotonic response of clean and silty sands. Géotechnique 57:273–288. doi:10.1680/geot.2007.57.3.273

Ng T, Asce F, Zhou W, Chang X (2016) Effect of particle shape and fine content on the behavior of binary mixture segregation of binary mixtures. J Eng Mech. doi:10.1061/(ASCE)EM.1943-7889.0001070

Pestana JM, Whittle AJ (1995) Compression model for cohesionless soils. Geotechnique 45:611–631. doi:10.1680/geot.1995.45.4.611

Pitman TD, Robertson PK, Sego DC (1994) Influence of fines on the collapse of loose sands. Can Geotech J 31:728–739. doi:10.1139/t94-084

Polito CP, Martin JR (2001) Effects of nonplastic fines on the liquefaction resistance of sands. J Geotech Geoenviron Eng 127:408–415. doi:10.1061/(ASCE)1090-0241(2001)127:5(408)

Rangaswamy K, Boominathan A, Rajagopal K (2010) Influence of initial conditions on liquefaction resistance of silty sands. Geomech Geoengin 5:199–211. doi:10.1080/17486021003706572

Rees SD (2010) Effects of fines on the undrained behavior of Christchurch sandy soils. University of Canterbury, Christchurch, New Zealand

Russell AR, Khalili N (2004) A bounding surface plasticity model for sands exhibiting particle crushing. Can Geotech J 41:1179–1192. doi:10.1139/t04-065

Sadrekarimi A, Olson SM (2011) Yield strength ratios, critical strength ratios, and brittleness of sandy soils from laboratory tests. Can Geotech J 48:493–510. doi:10.1139/T10-078

Scholtes L, Hicher P-Y, Sibille L (2010) Multiscale approaches to describe mechanical responses induced by particle removal in granular materials. C R Mec 338:627–638. doi:10.1016/j.crme.2010.10.003

Stamatopoulos CA (2010) An experimental study of the liquefaction strength of silty sands in terms of the state parameter. Soil Dyn Earthq Eng 30:662–678. doi:10.1016/j.soildyn.2010.02.008

Thevanayagam S, Shenthan T, Mohan S, Liang J (2002) Undrained fragility of clean sands, silty sands, and sandy silts. J Geotech Geoenviron Eng 128:849–859. doi:10.1061/(ASCE)1090-0241(2002)128:10(849)

Wan CF, Fell R (2008) Assessing the potential of internal instability and suffusion in embankment dams and their foundations. J Geotech Geoenviron Eng 134:401–407. doi:10.1061/(ASCE)1090-0241(2008)134:3(401)

Yamamuro JA, Covert KM (2001) Monotonic and cyclic liquefaction of very loose sands with high silt content. J Geotech Geoenviron Eng 127:314–324. doi:10.1061/(ASCE)1090-0241(2001)127:4(314)

Yamamuro JA, Lade PV (1999) Experiments and modelling of silty sands susceptible to static liquefaction. Mech Cohesive Frict Mater 4:545–564. doi:10.1002/(SICI)1099-1484(199911)4:6<545:AID-CFM73>3.0.CO;2-O

Yang SL (2004) Characterization of the properties of sand–silt mixtures. Norwegian University of Science and Technology

Yang S, Lacasse S, Sandven R (2006) Determination of the transitional fines content of mixtures of sand and non-plastic fines. Geotech Test J 29:1–6. doi:10.1520/GTJ14010

Zlatović S, Ishihara K (1995) On the influence of nonplastic fines on residual strength. In: First Int. Conf. Earthq. Geotech. Eng. Tokyo, Japan, pp 239–244

Acknowledgements

This research was supported by National Science Foundation through Grant Number CMMI-1537491.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chang, C.S., Meidani, M. & Deng, Y. A compression model for sand–silt mixtures based on the concept of active and inactive voids. Acta Geotech. 12, 1301–1317 (2017). https://doi.org/10.1007/s11440-017-0598-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-017-0598-1