Abstract

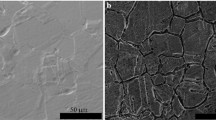

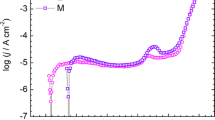

Semiconductor properties of the passive films formed on 316L and 2205 stainless steel were studied by Electrochemical Impedance Spectroscopy (EIS) in the high-temperature acetic acid. The results showed that the corrosion resistance of 2205 was higher than that of 316L, and the passive films formed on 316L and 2205 stainless steel showed p-type and n-type semiconductor behavior, respectively. Destruction and self-repairing of passive films were studied by using the constant current polarization method. The results showed that for 316L, the self-repairing process would occur when the destruction was lower than the critical extent or it would not do; for 2205, the self-repairing process only happened in a short time when the destruction was in the same extent as 316L.

Similar content being viewed by others

References

Moina C A, Varela F E. Semiconductor properties of passive oxide layers on binary tin + indium alloys. J Electroanalytical Chem, 1997, 427: 189–197

Lin Y H, Du R G, Hu R G. A correlation study of corrosion resistance and semiconductor properties for the electrochemically modified passive film of stainless steel. Acta Physico-chimica Sinica, 2005, 21:740–745

Linda G, Sonia B, Lorena J. Corrosion performance of the plasma nitrided 316L stainless steel. Surf Coatings & Technol, 2006, 201:4424–4429

Hu R G, Lin C J. XPS/SERS study of electrochemically modified passive film on stainless steel. J Chin Soc Corros Prot, 2000, 20:149–154

Zhang J X, Qiao Y X, Cao C N. The investigation and application of A.V. passivation of stainless steel. J Acta Chimica Sinica, 2002, 60:30–36

Li W S, Chen H Y, Yuan Z Z. Electrochemical investigations on pitting susceptibility of iron-based alloy. Electrochemistry, 2004, 10:397–341

Hakiki N B, Da Cunha, M B. Electronic structure of passive films formed on molybdenum-containing ferritic stainless steels. Electrochem Soc, 1996, 143: 3088–3094

Cheng X Q, Li X G, Du C W. Self-passivating behavior of 316L stainless steel in high-temperature acetic acid solution. J Sci & Technol Beijing, 2006, 28: 840–844

Paola A D. Semiconducting properties of passive films on stainless steels. Electrochim Acta, 1989, 34: 203–210

Hiroaki T, Shinji F, Osamu C. Semiconducting behavior of passive films formed on pure Cr and Fe-Cr alloys in sulfuric acid solution. Electrochim Acta, 2002, 47: 4357–4366

Li N, Li Y, Wang S G. Corrosion behavior of nanocrystalized bulk 304 stainless steel II. Protection of the passive film. J Chin Soc Corros Prot, 2007, 27: 142–146

Zhang X L, Zhang F Q, Song S L. Carrier concentration profiling in magnetic GaMnSb/GaSb investigated by electrochemistry capacitance-voltage profiler. Chin Sci Bull, 2002, 47: 1299–1301

Morrison S R. Electrochemistry of the Semiconductor and Metal Oxide Electrode. Beijing: Science Press, 1988

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by the National Natural Science Foundation of China (Grant No. 50871020)

About this article

Cite this article

Cheng, X., Li, X. & Du, C. Properties of passive film formed on 316L / 2205 stainless steel by Mott-Schottky theory and constant current polarization method. Chin. Sci. Bull. 54, 2239–2246 (2009). https://doi.org/10.1007/s11434-009-0158-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11434-009-0158-7