Abstract

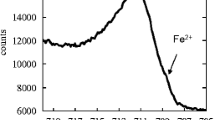

Mott–Schottky analysis and electrochemical and X-ray photoelectron spectroscopy (XPS) measurements were performed on passive films formed on low-C 13CrNiMo stainless steel with different applied heat treatments. Heat treatments render particular microstructural features of the alloy with a significant impact on the ability of the passive films to afford adequate protection against localized corrosion. A lower level of retained austenite in the substrate renders thinner passive films. Phosphates coexist with oxidized Fe(III) compounds as the prevailing species in the anodic layers. Mo was only detected in the oxide film formed on the sample with a higher retained austenite content.

Passive layers behave as n-type semiconductors with two types of donors, namely, shallow-level and deep-level states. The observed flat band potential V FB≅ -0.425 ± 0.005 V vs. standard calomel electrode (SCE) is independent of the thermal treatment of the alloy but under potential bias conditions at the corrosion potential the occurrence of the cathodic reaction on the oxide surface is hindered on the sample with higher retained austenite in its microstructure as compared to the sample with lower retained austenite content.

Similar content being viewed by others

References

Mesquita TJ, Chauveau E, Mantel M, Bouvier N, Koschel D (2014) Corrosion and metallurgical investigation of two supermartensitic stainless steels for oil and gas environments. Corros Sci 81:152–161

Della Rovere CA, Aquino JM, Ribeiro CR, Silva R, Alcântara NG, Kuri SE (2015) Corrosion behavior of radial friction welded supermartensitic stainless steel pipes. Mater Des 65:318–327

Vignal V, Ringeval S, Thiébaut S, Tabalaiev K, Dessolin C, Heintz O, Herbst F, Chassagnon R (2014) Influence of the microstructure on the corrosion behaviour of low-carbon martensitic stainless steel after tempering treatment. Corros Sci 85:42–51

Xu D, Liu Y, Ma Z, Li H, Yan Z (2014) Structural refinement of 00Cr13Ni5Mo2 supermartensitic stainless steel during single-stage intercritical tempering. Int J Min Metall Mater 21:279–288

Schmuki P, Böhni H (1995) Illumination effects on the stability of the passive film on iron. Electrochim Acta 40:775–783

Gervasi CA, Bilmes PD, Llorente CL (2007) In: Wang IS (ed) Corrosion research trends. New York, Nova Science Publishers

Bilmes PD, Llorente CL, Méndez CM, Gervasi CA (2009) Microstructure, heat treatment and pitting corrosion of 13CrNiMo plate and weld metals. Corros Sci 51:876–881

Gervasi CA, Méndez CM, Bilmes PD, Llorente CL (2011) Analysis of the impact of alloy microstructural properties on passive films formed on low-C 13CrNiMo martensitic stainless steels. Mater Chem Phys 126:178–182

Hakiki NE, Montemor MF, Ferreira MGS, da Cunha BM (2000) Semiconducting properties of thermally grown oxide films on AISI 304 stainless steel. Corros Sci 42:87–702

Gaben F, Vuillemin B, Oltra R (2004) Influence of the chemical composition and electronic structure of passive films grown on 316L SS on their transient electrochemical behavior. J Electrochem Soc 151:B595–B604

Szklarska-Smialowska Z (2002) In: Frankel GS, Isaacs HS, Scully JR, Sinclair JD (eds) Corrosion science: a retrospective and current status in honor of Rober P. Frankenthal. The Electrochemical society, New Jersey 251:265

Feng Z, Cheng X, Dong C, Xu L, Li X (2010) Passivity of 316L stainless steel in borate buffer solution studied by Mott–Schottky analysis, atomic absorption spectrometry and X-ray photoelectron spectroscopy. Corros Sci 52:3646–3653

Castro EB (1994) Analysis of the impedance response of passive iron. Electrochim Acta 39:2117–2123

Macdonald DD, Smedley SI (1990) An electrochemical impedance analysis of passive films on nickel(111) in phosphate buffer solutions. Electrochim Acta 35:1949–1956

Lai WY, Zhao WZ, Yin ZF, Zhang J (2012) EIS and XPS studies on passive film of AISI 304 stainless steel in dilute sulfuric acid solution. Surf Interf Anal 44:418–425

Bianchi G, Cerquetti A, Mazza F, Torchio S (1970) Chemical etching and pitting of stainless steel. Corros Sci 10:19–27

Brug GJ, Van Den Eeden ALG, Sluyters-Rehbach M, Sluyters JH (1984) The analysis of electrode impedances complicated by the presence of a constant phase element. J Electroanal Chem 176:275–295

Nicic I, Macdonald DD (2008) The passivity of type 316L stainless steel in borate buffer solution. J Nuc Mat 379:54–58

Tsuchiya H, Fujimoto S, Shibata T (2004) Semiconductive properties of passive films formed on Fe-18Cr in borate buffer solution. J Electrochem Soc 151:B39

Hamadou L, Kadri A, Benbrahim N (2010) Impedance investigation of thermally formed oxide films on AISI 304L stainless steel. Corros Sci 52:859–864

Amri J, Souier T, Malki B, Baroux B (2008) Effect of the final annealing of cold rolled stainless steels sheets on the electronic properties and pit nucleation resistance of passive films. Corros Sci 50:431–435

Schmuki P, Bohni H (1992) Metastable pitting and semiconductive properties of. J Electrochem Soc 139:1908–1913

Harrington SP, Devine TM (2009) The influence of the semiconducting properties of passive films on localized corrosion rates. ECS Trans 16:117–123

Gilbert JL, Mali SA (2012) In: Eliaz N (ed) Degradation of implant materials. New York, Springer

Hakiki NE (1996) Electronic structure of passive films formed on molybdenum-containing ferritic stainless steels. J Electrochem Soc 143:3088–3094

Hakiki NE, Boudin S, Rondot B, Da Cunha BM (1995) The electronic structure of passive films formed on stainless steels. Corros Sci 37:1809–1822

Kocijan A, Donik Č, Jenko M (2007) Electrochemical and XPS studies of the passive film formed on stainless steels in borate buffer and chloride solutions. Corros Sci 49:2083–2098

Montemor MF, Simoes AMP, Ferreira MGS, Da Cunha BM (1999) The role of Mo in the chemical composition and semiconductive behaviour of oxide films formed on stainless steels. Corros Sci 41:17–34

Zou D, Liu R, Li J, Zhang W, Wang D, Han Y (2014) Corrosion resistance and semiconducting properties of passive films formed on 00Cr13Ni5Mo2 supermartensitic stainless steel in Cl− environment. J Iron Steel Res Int 21:630–636

Strehblow H-H, Marcus P (2006) In: Marcus P, Mansfeld F (eds) Analytical methods in corrosion science and engineering. Boca Raton, CRC Press

Vayer M, Reynaud I, Erre R (2000) XPS characterisations of passive films formed on martensitic stainless steel: qualitative and quantitative investigations. J Mat Sci 35:2581–2587

Natarajan R, Palaniswamy N, Natesan M, Muralidharan V.S. (2009) XPS analysis of passive film on stainless steel. Open Corros J 2:114–124

Biesinger MC, Payne BD, Grosvenor AP, Lau LWM, Gerson AR, Smart RSC (2011) Resolving surface chemical states in XPS analysis of first row transition metals, oxides and hydroxides: Cr, Mn, Fe, Co and Ni. Appl Surf Sci 257:2717–2730

Jiang H, Wang J, Ding B (1992) Surface characterization of Ni64P20Fe16 amorphous alloy by X-ray photoelectron spectroscopy and auger electron spectroscopy. Ch J Met Sci Tech 8:157–162

Sieber IV, Hildebrand H, Virtanen S, Schmuki P (2006) Investigations on the passivity of iron in borate and phosphate buffers, pH 8.4. Corros Sci 48:3472–3488

Giacomelli C, Giacomelli FC, Bortolluzzi RL, Spinelli A (2006) Properties of potentiostatic passive films grown on iron electrodes immersed in weak-alkaline phosphate solutions. Anti-Corros Meth Mat 53:232–239

Giacomelli C, Spinelli A (2004) A potentiodynamic and SEM study of the behaviour of iron in pH 8.9-11.0 phosphate solutions. Anti-Corros Meth Mat 51:189–199

Acknowledgments

This work was financially supported by Agencia Nacional de Promoción Científica y Tecnológica of Argentina (ANPCYT, PICT 2013-0387), Consejo Nacional de Investigaciones Científicas y Técnicas (CONICET) and Comisión de Investigaciones Científicas de la Provincia de Buenos Aires (CICPBA). CLL, AEB, and CAG are researchers at CICPBA.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Gervasi, C.A., Méndez, C.M., Bolzán, A.E. et al. Chemical composition and electronic structure of anodic passive films on low-C 13CrNiMo stainless steel. J Solid State Electrochem 20, 1065–1074 (2016). https://doi.org/10.1007/s10008-015-2986-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-015-2986-5