Abstract

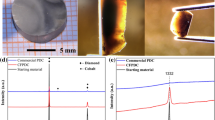

Thermal residual stress in Polycrystalline Diamond Compacts (PDCs) is mainly caused by the mismatch in the Coefficients of Thermal Expansion (CTE) between the polycrystalline diamond (PCD) layer and WC-Co substrate. In the PCD layer, the CTE of cobalt exhibit magnitudes four times larger than those of diamond. Cobalt content in the PCD layer has important effects on the thermal residual stress of PDCs. In this work, the effects of cobalt content on thermal residual stress in PCDs were investigated by the Finite Element Method (FEM). The simulation results show that the thermal residual stress decreases firstly, and then increases with increasing cobalt content (1 vol.%–20 vol.%), which reaches a minimum value when the cobalt content is about 10 vol.%. The FEM analysis results are in agreement with our experimental results. It will provide an effective method for further designing and optimizing PDC properties.

Similar content being viewed by others

References

Hall HT. Sintered diamond: A synthetic carbonado. Science 1970, 169: 868–869

Paggett J W, Drake E F, Krawitz A D, et al. Residual stress and stress gradients in Polycrystalline Diamond Compacts. Int J Refract Met Hard Mater, 2002, 20: 187–194

Wentorf R H, Devries RC, Bundy F P. Sintered superhard materials. Science, 1980, 208: 873–880

Krawitz A D, Winholtz R A, Drake E F, et al. Residual stresses in Polycrystalline Diamond Compacts. Int J Refract Met Hard Mater, 1999, 17: 117–122

Vohra Y K, Catledge S A, Ladi R, et al. Micro-Raman stress investigations and X-ray diffraction analysis of polycrystalline diamond (PCD) tools. Diamond Relat Mater, 1996, 5:1159–1165

Chen F, Xu G, Ma C D, et al. Thermal residual stress of Polycrystalline Diamond Compacts. Trans Nonferrous Metals Soc China, 2010, 20: 227–232

Xu G P, Chen Q W, Yin Z M, et al. The effect of thickness of diamond layer on residual stresses in Polycrystalline Diamond Compact (in Chinese). Chin J High Press Phys, 2009, 23(1): 24–30

Meng Q H, Li Y J. Handbook of Abrasives Technical (in Chinese). Beijing: Weapon Industry Press, 1993

Ma Q F. Practical Handbook of Thermal Physical Properties (in Chinese). Beijing: China Agricultural Machinery Press, 1986

Lu Y M, Zhang C F. Foreign Carbide (in Chinese). Beijing: Metallurgical Industry Press, 1976

ASM International. ASM Metals Handbook. Properties and Selection: Nonferrous Alloys and Special Purpose Materials vol. 2 (in Chinese). 9th ed. Beijing: Machinery Industry Press, 1979

Kingery W D. The thermal conductivity of ceramic dielectrics. In: Burke J E, ed. Progress in Ceramic Science, vol. 2. New York: Pergamon Press, 1962

Fahmy A A, Ragai A N. Thermal expansion behavior of two-phase solids. J Appl Phys, 1970, 41: 5108–5111

Turner P S. Thermal expansion stress in reinforced plastics. J Res NBS, 1946, 37: 239–250

Weng G J. Some elastic properties of reinforced solids, with special reference to isotropic ones containing spherical inclusions. Int J Eng Sci, 1984, 22: 845–856

Benveniste Y. A new approach to the application of Mori-Tanaka’s theory in composite materials. Mech Mater, 1987, 6: 147–157

Touloukian Y S, Buyco H. Specific Heat: Metallic Elements and Alloys. New York: IFI/Plenum Press, 1970

Jia H S, Ma H A, Jia X P. Research on Polycrystalline Diamond Compact (PDC) with low residual stress prepared using nickel-based additive. Int J Refract Met Hard Mater, 2011, 29: 64–67

Zai G H. Manufacture the Sintered Body of Superhard Materials (in Chinese). Zhengzhou: China Abrasive Tools Industry Intelligence Networks, 1993

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Z., Jia, H., Ma, H. et al. FEM analysis on the effect of cobalt content on thermal residual stress in polycrystalline diamond compact (PDC). Sci. China Phys. Mech. Astron. 55, 639–643 (2012). https://doi.org/10.1007/s11433-012-4654-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11433-012-4654-4