Abstract

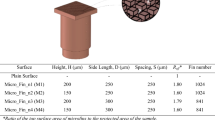

Aluminum-based microgroove surfaces with reentrant cavities (MSRCs) were fabricated by two staggered ploughing/extrusion processes to meet the requirements of lightweight phase change heat transfer devices. Five MSRCs with different stagger angles between cavities and microgrooves (MGs) were fabricated to study the effect of stagger angle on capillary performance. Capillary rise and permeability tests were performed on all MSRCs and the results were compared with MGs having the same processing parameters. It was found that MSRCs with smaller stagger angles have higher capillary height, and the maximum enhancement maintained by MSRC45 was about 54.84%. However, MSRCs with larger stagger angles were found to have higher permeability. Therefore, the capillary parameter K·ΔPcap was used as a comprehensive index to evaluate these wicks. MSRC90 and MSRC75 obtained the largest K·ΔPcap values without and with the effect of gravity considered, respectively. Although all MSRCs had a higher capillary rise height than MGs, smaller stagger angles (≤ 60°) seriously reduced the permeability of MSRCs and even resulted in smaller K·ΔPcap value than that of MGs when calculated considering the effect of gravity. Therefore, MSRCs with larger stagger angles (≥ 75°) may be the optimum wicks due to the good balance between capillary pressure and permeability.

Similar content being viewed by others

References

Lee D W, Cho S W, Kim Y J. Numerical study on the heat dissipation characteristics of high-power LED module. Sci China Tech Sci, 2013, 56: 2150–2155

Deng Y C, Quan Z H, Zhao Y H, et al. Experimental investigations on the heat transfer characteristics of micro heat pipe array applied to flat plate solar collector. Sci China Tech Sci, 2013, 56: 1177–1185

Sun Y, Zhang S, Chen G, et al. Experimental and numerical investigation on a novel heat pipe based cooling strategy for permanent magnet synchronous motors. Appl Thermal Eng, 2020, 170: 114970

Zhao Y, Chang S, Yang B, et al. Experimental study on the thermal performance of loop heat pipe for the aircraft anti-icing system. Int J Heat Mass Transfer, 2017, 111: 795–803

Fok S C, Shen W, Tan F L. Cooling of portable hand-held electronic devices using phase change materials in finned heat sinks. Int J Thermal Sci, 2010, 49: 109–117

Aslan Y, Puskely J, Roederer A, et al. Heat transfer enhancement in passively cooled 5G base station antennas using thick ground planes. In: 2019 13th European Conference on Antennas and Propagation (EuCAP). Krakow, Poland, 2019. 1–5

Qu J, Wu H Y. Flow visualization of silicon-based micro pulsating heat pipes. Sci China Tech Sci, 2010, 53: 984–990

Tang H, Tang Y, Yuan W, et al. Fabrication and capillary characterization of axially micro-grooved wicks for aluminium flat-plate heat pipes. Appl Thermal Eng, 2018, 129: 907–915

Lee C Y, Zhang B J, Kim K J. Morphological change of plain and nano-porous surfaces during boiling and its effect on nucleate pool boiling heat transfer. Exp Thermal Fluid Sci, 2012, 40: 150–158

Tang Y, Chi Y, Wan Z P, et al. A novel finned micro-groove array structure and forming process. J Mater Process Tech, 2008, 203: 548–553

Tang Y, Deng D, Huang G, et al. Effect of fabrication parameters on capillary performance of composite wicks for two-phase heat transfer devices. Energy Convers Manage, 2013, 66: 66–76

Go J S. Quantitative thermal performance evaluation of a cost-effective vapor chamber heat sink containing a metal-etched microwick structure for advanced microprocessor cooling. Sens Actuat A-Phys, 2005, 121: 549–556

Zhang S, Sun Y, Yuan W, et al. Effects of heat flux, mass flux and channel width on flow boiling performance of porous interconnected microchannel nets. Exp Thermal Fluid Sci, 2018, 90: 310–318

Fasasi A Y, Mwenifumbo S, Rahbar N, et al. Nano-second UV laser processed micro-grooves on Ti6Al4V for biomedical applications. Mater Sci Eng-C, 2009, 29: 5–13

Deng D, Tang Y, Zeng J, et al. Characterization of capillary rise dynamics in parallel micro V-grooves. Int J Heat Mass Transfer, 2014, 77: 311–320

Wang X, Tang T, Chen P. Investigation into performance of a heat pipe with micro grooves fabricated by extrusion-ploughing process. Energy Convers Manage, 2009, 50: 1384–1388

Zeng J, Zhang S, Chen G, et al. Experimental investigation on thermal performance of aluminum vapor chamber using micro-grooved wick with reentrant cavity array. Appl Thermal Eng, 2018, 130: 185–194

Wu R, Kharaghani A, Tsotsas E. Capillary valve effect during slow drying of porous media. Int J Heat Mass Transfer, 2016, 94: 81–86

Wu R, Kharaghani A, Tsotsas E. Two-phase flow with capillary valve effect in porous media. Chem Eng Sci, 2016, 139: 241–248

Zeng J, Lin L, Tang Y, et al. Fabrication and capillary characterization of micro-grooved wicks with reentrant cavity array. Int J Heat Mass Transfer, 2017, 104: 918–929

Kuo C J, Peles Y. Local measurement of flow boiling in structured surface microchannels. Int J Heat Mass Transfer, 2007, 50: 4513–4526

Zhou S, Xu X, Sammakia B G. Modeling of boiling flow in microchannels for nucleation characteristics and performance optimization. Int J Heat Mass Transfer, 2013, 64: 706–718

Iyi D, Hasan R. Numerical investigation of the effect of moisture on buoyancy-driven low turbulence flow in an enclosed cavity. Int J Heat Mass Transfer, 2019, 136: 543–554

Chen B, Gao D, Liang Y, et al. Experimental investigation of atomization and droplet turbulence characteristics of a twin-fluid nozzle with different self-excited vibrating cavity structures. Exp Thermal Fluid Sci, 2018, 99: 525–536

Padilla E L M, Silveira-Neto A. Large-eddy simulation of transition to turbulence in natural convection in a horizontal annular cavity. Int J Heat Mass Transfer, 2008, 51: 3656–3668

Sun Y, Chen G, Zhang S, et al. Pool boiling performance and bubble dynamics on microgrooved surfaces with reentrant cavities. Appl Thermal Eng, 2017, 125: 432–442

Tang Y, Deng D, Lu L, et al. Experimental investigation on capillary force of composite wick structure by IR thermal imaging camera. Exp Thermal Fluid Sci, 2010, 34: 190–196

Deng D, Tang Y, Huang G, et al. Characterization of capillary performance of composite wicks for two-phase heat transfer devices. Int J Heat Mass Transfer, 2013, 56: 283–293

Washburn E W. The dynamics of capillary flow. Phys Rev, 1921, 17: 273–283

Kline S J, McClintock F A. Describing uncertainties in single-sample experiments. Mech Eng, 1953, 75: 3–9

Hamraoui A, Nylander T. Analytical approach for the Lucas-Washburn equation. J Colloid Interface Sci, 2002, 250: 415–421

Radulovic J, Sefiane K, Shanahan M E R. Capillary rise of superspreaders. J Colloid Interface Sci, 2011, 361: 643–648

Herrera B, Chejne F, Mantelli M B H, et al. Population balance for capillary limit modeling in a screen mesh wick heat pipe working with nanofluids. Int J Thermal Sci, 2019, 138: 134–158

Singh R, Akbarzadeh A, Mochizuki M. Experimental determination of wick properties for loop heat pipe applications. J Por Media, 2009, 12: 759–776

Semenic T, Lin Y Y, Catton I. Thermophysical properties of biporous heat pipe evaporators. J Heat Transfer, 2008, 130: 022602

Suga K, Matsumura Y, Ashitaka Y, et al. Effects of wall permeability on turbulence. Int J Heat Fluid Flow, 2010, 31: 974–984

Author information

Authors and Affiliations

Corresponding authors

Additional information

This work was supported by the National Natural Science Foundation of China (Grant No. 51905352), the Science and Technology Plan of Guangdong, China (Grant No. 2019B090910001), the Basic and Applied Research Foundation of Guangdong Province (Grant No. 2020A1515011039), the Basic Research Foundation of Shenzhen (Grant No. JCYJ2019080814400-3701), and the Open Fund of Hubei Key Laboratory of Mechanical Transmission and Manufacturing Engineering at Wuhan University of Science and Technology (Grant No. MTMEOF2019A02).

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Sun, Y., Liang, F., Tang, Y. et al. Effect of stagger angle on capillary performance of microgroove structures with reentrant cavities. Sci. China Technol. Sci. 64, 1436–1446 (2021). https://doi.org/10.1007/s11431-020-1783-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-020-1783-x