Abstract

The characterization of fatigue crack propagation behavior is crucial for performance and reliability evaluation of aerospace materials. In this study, high-temperature (maximum: 650°C) fatigue crack propagation experiments of Ni-based superalloy GH4169 were conducted. The bi-prism-based single-lens 3D digital image correlation (BSL 3D DIC) technique was used to in-situ measure the displacement and strain fields near fatigue crack tip. Based on the deformation information, the mode I stress intensity factor range ΔK and the crack opening displacement (COD) were determined for characterizing the crack closure effect. As the major fatigue crack growth model, the parameters of modified Paris’ law were obtained based on the effective stress intensity factor range ΔKeff and the fatigue crack propagation rate (FCPR). Additionally, two kinds of J integrals, JP (path integral method) and JK (stress intensity factor K method), were used to evaluate the small-scale yielding approximation.

Similar content being viewed by others

References

Salvati E, O’Connor S, Sui T, et al. A study of overload effect on fatigue crack propagation using EBSD, FIB-DIC and FEM methods. Eng Fract Mech, 2016, 167: 210–223

ASTM E647-15e1. Standard test method for measurement of fatigue crack growth rates. ASTM International, West Conshohocken, PA, 2008

Huang X, Wang L, Hu Y, et al. Fatigue crack propagation behavior of Ni-based superalloys after overloading at elevated temperatures. Prog Nat Sci-Mater Int, 2016, 26: 197–203

Paris P, Erdogan F. A critical analysis of crack propagation laws. J Basic Eng, 1963, 85: 528–533

Nowell D, Paynter R J H, De Matos P F P. Optical methods for measurement of fatigue crack closure: Moiré interferometry and digital image correlation. Fatigue Fract Eng Mater Struct, 2010, 33: 778–790

Larsen J M, Nicholas T. Cumulative-damage modeling of fatigue crack growth in turbine engine materials. Eng Fract Mech, 1985, 22: 713–730

Chudnovsky A. Slow crack growth, its modeling and crack-layer approach: A review. Int J Eng Sci, 2014, 83: 6–41

Wolf E. Fatigue crack closure under cyclic tension. Eng Fract Mech, 1970, 2: 37–45

Chang T, Li G, Hou J. Effects of applied stress level on plastic zone size and opening stress ratio of a fatigue crack. Int J Fatigue, 2005, 27: 519–526

Díaz F, Yates J R, Patterson E A. Some improvements in the analysis of fatigue cracks using thermoelasticity. Int J Fatigue, 2004, 26: 365–376

Kim K S, Kim S C, Shim C S, et al. A study of overload effects on fatigue crack propagation under cyclic loading using ESPI system. In: Lee S S, Yoon D J, Lee J H, et al, eds. Key Engineering Materials, Vols. 270–273. Advances in Nondestructive Evaluation. Jeju Island: Trans Tech Publications, 2004. 709–714

Zhang Q, Jiang Z, Jiang H, et al. On the propagation and pulsation of Portevin-Le Chatelier deformation bands: An experimental study with digital speckle pattern metrology. Int J Plast, 2005, 21: 2150–2173

Jiang Z, Zhang Q, Jiang H, et al. Spatial characteristics of the Portevin-Le Chatelier deformation bands in Al-4at%Cu polycrystals. Mater Sci Eng-A, 2005, 403: 154–164

Mokhtarishirazabad M, Lopez-Crespo P, Moreno B, et al. Optical and analytical investigation of overloads in biaxial fatigue cracks. Int J Fatigue, 2017, 100: 583–590

Xiang G F, Zhang Q C, Liu H W, et al. Time-resolved deformation measurements of the Portevin-Le Chatelier bands. Scripta Mater, 2007, 56: 721–724

Chen J L, Zhang X C, Zhan N. Extended digital image correlation method for micro-region deformation measurement. Sci China Tech Sci, 2011, 54: 1355–1361

Su Y, Zhang Q, Gao Z, et al. Fourier-based interpolation bias prediction in digital image correlation. Opt Express, 2015, 23: 19242–19260

Gao Y, Cheng T, Su Y, et al. High-efficiency and high-accuracy digital image correlation for three-dimensional measurement. Optics Lasers Eng, 2015, 65: 73–80

Pan B, Tian L, Song X. Real-time, non-contact and targetless mesurement of vertical deflection of bridges using off-axis digital image correlation. NDT E Int, 2016, 79: 73–80

Pan B, Qian K, Xie H, et al. Two-dimensional digital image correlation for in-plane displacement and strain measurement: A review. Meas Sci Technol, 2009, 20: 062001

Riddell W T, Piascik R S, Sutton M A, et al. Determining fatigue crack opening loads from near-crack-tip displacement measurements. In: McClung R, Newman J, eds. Advances in Fatigue Crack Closure Measurementand Analysis: Second Volume. WestConshohocken, PA: ASTM International, 1999. 157–174

Sutton M A, Zhao W, McNeill S R, et al. Local crack closure measurements: Development of a measurement system using computer vision and a far-field microscope. In: McClung R, Newman J, eds. Advances in Fatigue Crack Closure Measurement and Analysis: Second Volume. West Conshohocken, PA: ASTM International, 1999. 145–156

Hu D, Mao J, Song J, et al. Experimental investigation of grain size effect on fatigue crack growth rate in turbine disc superalloy GH4169 under different temperatures. Mater Sci Eng-A, 2016, 669: 318–331

Nowell D, Kartal M E, De Matos P F P. Digital image correlation measurement of near-tip fatigue crack displacement fields: Constant amplitude loading and load history effects. Fatigue Fract Eng Mater Struct, 2013, 36: 3–13

O’Connor S J, Nowell D, Dragnevski K I. Measurement of fatigue crack deformation on the macro- and micro-scale: Uniform and non-uniform loading. Int J Fatigue, 2016, 89: 66–76

Rabbolini S, Pataky G J, Sehitoglu H, et al. Fatigue crack growth in Haynes 230 single crystals: An analysis with digital image correlation. Fatigue Fract Engng Mater Struct, 2015, 38: 583–596

Mao W G, Chen J, Si M S, et al. High temperature digital image correlation evaluation of in-situ failure mechanism: An experimental framework with application to C/SiC composites. Mater Sci Eng-A, 2016, 665: 26–34

Pan B, Wu D, Wang Z, et al. High-temperature digital image correlation method for full-field deformation measurement at 1200°C. Meas Sci Technol, 2011, 22: 015701

Pan B, Wu D, Xia Y. High-temperature deformation field measurement by combining transient aerodynamic heating simulation system and reliability-guided digital image correlation. Optics Lasers Eng, 2010, 48: 841–848

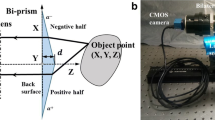

Wu L, Zhu J, Xie H, et al. Single-lens 3D digital image correlation system based on a bilateral telecentric lens and a bi-prism: Systematic error analysis and correction. Optics Lasers Eng, 2016, 87: 129–138

Wu L F, Zhu J G, Xie H M, et al. An accurate method for shape retrieval and displacement measurement using bi-prism-based single lens 3D digital image correlation. Exp Mech, 2016, 56: 1611–1624

Wu L, Zhu J, Xie H. Single-lens 3D digital image correlation system based on a bilateral telecentric lens and a bi-prism: Validation and application. Appl Opt, 2015, 54: 7842–7850

Wu L F, Zhu J G, Xie H M. A modified virtual point model of the 3D DIC technique using a single camera and a bi-prism. Meas Sci Technol, 2014, 25: 115008

Wu L F, Yin Y J, Zhang Q, et al. Bi-prism-based single-lens three dimensional digital image correlation system with a long working distance: Methodology and application in extreme high temperature deformation test. Sci China Tech Sci, 2018, 61: 37–50

Wu L F. Research on the bi-prism-based single lens three dimensional digital image correlation method (in Chinese). Dissertation of Doctoral Degree. Beijing: Tsinghua University, 2017

Yin Y, Wu L, Li J, et al. High-temperature fracture mechanics parameter measurement and yielding zone analysis of superalloy GH4169 based on single-lens 3D digital image correlation. Exp Mech, 2019, doi: https://doi.org/10.1007/s11340-019-00490-7

Yin Y J, Xie H M, He W. In situ SEM-DIC technique and its application to characterize the high-temperature fatigue crack closure effect. Sci China Tech Sci, 2019, doi: https://doi.org/10.1007/s11431-018-9477-6

Gao H L, Jiang W, Liu H, et al. The measurement of the fatigue crack-tip displacement and strain fields under high frequency resonant loading applying DIC method. In: Yan G, ed. Applied Mechanics and Materials, Vol 710. Innovations in Material Science, Applied Mechanics, Control and Information Technologies. Switzerland: Trans Tech Publications, 2015. 83–90

de Matos P F P, Nowell D. Experimental and numerical investigation of thickness effects in plasticity-induced fatigue crack closure. Int J Fatigue, 2009, 31: 1795–1804

Carroll J, Efstathiou C, Lambros J, et al. Investigation of fatigue crack closure using multiscale image correlation experiments. Eng Fract Mech, 2009, 76: 2384–2398

Yoneyama S, Morimoto Y, Takashi M. Automatic evaluation of mixed-mode stress intensity factors utilizing digital image correlation. Strain, 2006, 42: 21–29

Yates J R, Zanganeh M, Tai Y H. Quantifying crack tip displacement fields with DIC. Eng Fract Mech, 2010, 77: 2063–2076

Hosdez J, Witz J F, Martel C, et al. Fatigue crack growth law identification by digital image correlation and electrical potential method for ductile cast iron. Eng Fract Mech, 2017, 182: 577–594

Gonzáles G L G, González J A O, Castro J T P, et al. A J-integral approach using digital image correlation for evaluating stress intensity factors in fatigue cracks with closure effects. Theor Appl Fract Mech, 2017, 90: 14–21

Malitckii E, Remes H, Lehto P, et al. Strain accumulation during microstructurally small fatigue crack propagation in bcc Fe-Cr ferritic stainless steel. Acta Mater, 2018, 144: 51–59

Author information

Authors and Affiliations

Corresponding authors

Additional information

This work was supported by the National Natural Science Foundation of China (Grant Nos. 11672153 & 11802156), and the China Postdoctoral Science Foundation (Grant No. 2018M641331).

Rights and permissions

About this article

Cite this article

Yin, Y., He, W., Xie, H. et al. High-temperature fatigue crack propagation study of superalloy GH4169 by single-lens 3D digital image correlation. Sci. China Technol. Sci. 63, 693–704 (2020). https://doi.org/10.1007/s11431-019-9525-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-019-9525-3