Abstract

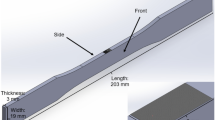

Residual stress plays a vital role in the structural strength and stability. The determination of residual stress at single-point has become mature at present. However, the method to determine residual stress distribution is still in shortage. For this problem, a finite element approach combined with slot milling method was developed in this study. In the method, firstly a slot is milled on the specimen surface to release the residual stress and then the released displacement field is measured by optical method, such as digital image correlation (DIC), finally the finite element approach is used to determine the residual stress distribution along the slot. In order to verify the feasibility of the method, it was applied to study the residual stress introduced by shot peening, mainly about the stress distribution along the direction vertical to the shot peened surface. Since the influence depth of shot peening was too small, we utilized focused ion beam (FIB) to determine the microscale residual stress distribution. The result measured by X-ray diffraction (XRD) demonstrated that the method was feasible to determine the residual stress distribution.

Similar content being viewed by others

References

James M N. Residual stress influences on structural reliability. Eng Failure Anal, 2011, 18: 1909–1920

Ma C H, Huang J H, Chen H. Residual stress measurement in textured thin film by grazing-incidence X-ray diffraction. Thin Solid Films, 2002, 418: 73–78

Kang Y, Qiu Y, Lei Z, et al. An application of Raman spectroscopy on the measurement of residual stress in porous silicon. Opt Lasers Eng, 2005, 43: 847–855

Choi H C, Park J H. Prediction of residual stress distribution in multi-stacked thin film by curvature measurement and iterative FEA. J Mater Sci Technol, 2005, 19: 1065–1071

Winiarski B, Gholinia A, Tian J, et al. Submicron-scale depth profiling of residual stress in amorphous materials by incremental focused ion beam slotting. Acta Mater, 2012, 60: 2337–2349

Schajer G S. Advances in hole-drilling residual stress measurements. Exp Mech, 2010, 50: 159–168

Zhu R H, Xie H M, Zhu J G, et al. A micro-scale strain rosette for residual stress measurement by SEM Moiré method. Sci China Phys Mech Astron, 2014, 57: 716–722

Schajer G S. Use of displacement data to calculate strain gauge response in non-uniform strain fields. Strain, 1993, 29: 9–13

Barsanti M, Beghini M, Bertini L. First-order correction to counter the effect of eccentricity on the hole-drilling integral method with straingage rosettes. J Strain Anal Eng Des, 2016, 51: 431–444

Winiarski B, Withers P J. Micron-scale residual stress measurement by micro-hole drilling and digital image correlation. Exp Mech, 2012, 52: 417–428

Zhu R, Xie H, Dai X, et al. Residual stress measurement in thin films using a slitting method with geometric phase analysis under a dual beam (FIB/SEM) system. Meas Sci Technol, 2014, 25: 095003

Sabaté N, Vogel D, Gollhardt A, et al. Digital image correlation of nanoscale deformation fields for local stress measurement in thin films. Nanotechnology, 2006, 17: 5264

Kim K, Jung H. Nondestructive testing of residual stress on the welded part of butt-welded A36 plates using electronic speckle pattern interferometry. Nucl Eng Technol, 2016, 48: 259–267

Kang K J, Yao N, He M Y, et al. A method for in situ measurement of the residual stress in thin films by using the focused ion beam. Thin Solid Films, 2003, 443: 71–77

Winiarski B, Langford R M, Tian J, et al. Mapping residual stress distributions at the micron scale in amorphous materials. Metall Mat Trans A, 2010, 41: 1743–1751

Mansilla C, Ocelík V, De Hosson J T M. Local residual stress measurements on nitride layers. Mater Sci Eng A, 2015, 636: 476–483

Lunt A J G, Korsunsky A M. A review of micro-scale focused ion beam milling and digital image correlation analysis for residual stress evaluation and error estimation. Surface Coatings Technol, 2015, 283: 373–388

Lecompte D, Sol H, Vantomme J, et al. Identification of elastic orthotropic material parameters based on ESPI measurements. In: SEM annual conference and exposition on experimental and applied mechanics. Portland, 2005

Torres M. An evaluation of shot peening, residual stress and stress relaxation on the fatigue life of AISI 4340 steel. Int J Fatigue, 2002, 24: 877–886

Zhang P, Lindemann J. Influence of shot peening on high cycle fatigue properties of the high-strength wrought magnesium alloy AZ80. Scripta Mater, 2005, 52: 485–490

Reyntjens S, Puers R. A review of focused ion beam applications in microsystem technology. J Micromech Microeng, 2001, 11: 287–300

Chu T C, Ranson W F, Sutton M A. Applications of digital-imagecorrelation techniques to experimental mechanics. Exp Mech, 1985, 25: 232–244

Zhu R, Xie H, Xue Y, et al. Fabrication of speckle patterns by focused ion beam deposition and its application to micro-scale residual stress measurement. Meas Sci Technol, 2015, 26: 095601

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhu, R., Zhang, Q., Xie, H. et al. Determination of residual stress distribution combining slot milling method and finite element approach. Sci. China Technol. Sci. 61, 965–970 (2018). https://doi.org/10.1007/s11431-017-9131-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-017-9131-0