Abstract

Purpose

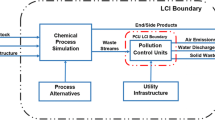

In life-cycle assessment (LCA), environmental technologies are often modelled as “black-box processes”, where inputs and outputs are typically not linked through physical and/or (bio) chemical relationships. This limits transparency and usability of environmental modelling of resource systems for which the conversion of materials and chemical substances in the materials is essential for the environmental performance. We introduce an advanced “process-oriented” modelling framework allowing quantitative and parameterised physical-chemical relationships between input material composition, conversion process units and subsequent output products, promoting mass and substance balanced conversion modelling and environmental assessment.

Methods

A dedicated LCA model, EASETECH, has been used to provide a user-friendly platform for performing advanced LCA of complex technologies, without the need for additional software/tools. In the modelling framework, the technology is subdivided into individual unit processes. In each process, the characterisation of the input feedstock material into biochemical, physical, chemical and nutritional properties is taken into consideration in each multi-output production flow. For each unit process, the processes governing the mass/energy/substance transition and transformation are described by mathematical equations (i.e. relationships between inputs and outputs) through the use of parameters. A range of new operators were developed to establish these relationships that allow for non-linear responses whereby changes in one flow can give a non-linear response in other flows. The modelling framework and the involved operators are explained and applied to a biorefinery case study.

Results and discussion

The model facilitates “tracking” of the feedstock material properties from the input to the final products, by establishing mass, substance and energy balances for each conversion unit process. In addition, the process-oriented modelling framework appropriately represents material/substance transition and transformations. The choice of process parameters has considerable importance for the overall results. This was illustrated by one-at-a-time changes in parameter values in two different biorefinery unit processes (i.e. hydrolysis, and fermentation and distillation). In addition, the relevance of feedstock characteristics for the performance of the individual unit processes was proved with fixed parameter sets with different feedstocks. The biorefinery case study demonstrated that the LCA model can be applied to technology cases with different process configurations (e.g. different efficiencies) and different input feedstock properties, where it automatically adjusts to these changes in properties.

Conclusions

The advanced process-oriented modelling framework offers more flexible modelling of the conversion technology than previously available, improved options for technology development in view of environmental performance, and potentially more accurate results. This provides a significantly improved basis for environmental modelling and decision-making in relation to resource systems.

Similar content being viewed by others

Abbreviations

- CT:

-

Composite transformer

- FD:

-

Fraction distributor

- FG:

-

Fraction generator

- FH:

-

Fraction hub

- FT:

-

Fraction transformer

- GW:

-

Global warming

- LCA:

-

Life-cycle assessment

- LCI:

-

Life-cycle inventory

- MD:

-

Material distributor

- MF:

-

Material flow

- MG:

-

Material generator

- NG:

-

Natural gas

- RED:

-

Renewable Energy Directive

- RF:

-

Residue flow

- SD:

-

Substance distributor

- SG:

-

Substance generator

- SH:

-

Substance hub

- ST:

-

Substance transformer

References

Allesch A, Brunner PH (2015) Material flow analysis as a decision support tool for waste management: a literature review. J Ind Ecol 19:753–764

Arora P, Hoadley A, Mahajani S, Ganesh A (2016) Multi-level modelling of sustainable chemical production: from CFD to LCA. In: Computer aided chemical engineering. Elsevier 38:499–504. https://doi.org/10.1016/B978-0-444-63428-3.50088-6

Arvidsson R, Tillman A-M, Sandén BA et al (2017) Environmental assessment of emerging technologies: recommendations for prospective LCA. J Ind Ecol 00:1–9

ASPEN (2019). https://www.aspentech.com/. Accessed 12 Feb 2019

Asprion N, Bortz M (2018) Process modeling, simulation and optimization: from single solutions to a multitude of solutions to support decision making. Chemie Ing Tech 90:1727–1738

Astrup TF, Pivnenko K, Eriksen MK, Boldrin A (2018) Life cycle assessment of waste management: are we addressing the key challenges ahead of us? J Ind Ecol 22:1000–1004

Bernstad Saraiva A (2017) System boundary setting in life cycle assessment of biorefineries: a review. Int J Environ Sci Technol 14:435–452

Bisinella V, Götze R, Conradsen K et al (2017) Importance of waste composition for life cycle assessment of waste management solutions. J Clean Prod 164:1180–1191

Brunet R, Cortés D, Guillén-Gosálbez G et al (2012) Minimization of the LCA impact of thermodynamic cycles using a combined simulation-optimization approach. Appl Therm Eng 48:367–377

Brunner PH, Rechberger H (2016) Handbook of material flow analysis. CRC Press, Taylor & Francis Group, Boca Raton 453 pp

CHEMCAD (2019) https://www.chemstations.com/. Accessed 20 July 2019

Clavreul J, Baumeister H, Christensen TH, Damgaard A (2014) An environmental assessment system for environmental technologies. Environ Model Softw 60:18–30

Danish Ministry of Food, Agriculture and Fisheries (2018) Plantedirektoratet Bekendtgørelse nr. 1008 af 02 juli 2018 om jordbrugets anvendelse af gødning og om plantedække i planperioden 2018/2019. Available at https://www.retsinformation.dk/pdfPrint.aspx?id=202375 (accessed 17 June 2019).

EC-JRC (2010) International Reference Life Cycle Data System (ILCD) Handbook—general guide for life cycle assessment—detailed guidance. Publications office of the European Union, Luxembourg. https://doi.org/10.2788/38479

EPLCA (2019) European Platform on Life Cycle Assessment. List of tools. Internet site developed by the European Commission JRC, Directorate D, Sustainable Resources. Retrieved from: http://eplca.jrc.ec.europa.eu/ResourceDirectory/faces/tools/toolList.xhtml. Accessed 12 Feb 2019

European Commission (2017) Horizon 2020 -Work Programme 2014–2015 9. Food security, sustainable agriculture and forestry, marine and maritime and inland water research and the bioeconomy. Retrieved from http://www.iuav.it/Ricerca1/BANDI/PROGRAMMI-/INTERNAZIO/HORIZON-20/WORKPROGR/Societal-c/h2020-wp1820-food_en.pdf. Accessed 20 Feb 2019

European Parliament and the Council of the European Union (2009) Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009. Off J Eur Union 140(16):16–62. https://doi.org/10.3000/17252555.L_2009.140.eng

Gaha R, Benamara A, Yannou B (2017) Proposition of eco-feature: a new CAD / PLM data model for an LCA tool. In: Haddar M, Chaari F, Benamara A, Chouchane M, Karra C, Aifaoui N (eds) Design and Modeling of Mechanical Systems—III. CMSM 2017. Lecture Notes in Mechanical Engineering. Springer, Cham, pp 763–770. https://doi.org/10.1007/978-3-319-66697-6_74.

Gentil EC, Damgaard A, Hauschild M et al (2010) Models for waste life cycle assessment: review of technical assumptions. Waste Manag 30:2636–2648

Götze U, Hertel A, Schmidt A, Päßler E (2014) Technology and manufacturing process selection. Springer London, London

Henriksen T, Astrup TF, Damgaard A (2018) Linking data choices and context specificity in life cycle assessment of waste treatment technologies: a landfill case study. J Ind Ecol 22:1039–1049

IPCC (2013) Climate change 2013: the physical science basis. In: Stocker TF, Qin D, Plattner G-K, Tignor M, Allen SK, Boschung J, Nauels A, Xia Y, Bex V, Midgley PM (eds) Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change. Cambridge University Press, Cambridge, United Kingdom and New York, NY, USA, 1535 pp. https://doi.org/10.1017/CBO9781107415324

ISO (2006a) Environmental management—life cycle assessment—requirements and guidelines. ISO 14044, Geneva

ISO (2006b) Environmental management—life cycle assessment—principles and framework. ISO 14040, Geneva

Jacquemin L, Pontalier P-Y, Sablayrolles C (2012) Life cycle assessment (LCA) applied to the process industry: a review. Int J Life Cycle Assess 17:1028–1041

Jain P, Dyson B, Tolaymat TM, Ingwersen W (2015) A comparative analysis of life-cycle assessment tools for end-of-life materials management systems. U.S. Environmental Protection Agency, Washington, DC EPA/600/R-15/232

Kikuchi Y, Kimura S, Okamoto Y, Koyama M (2014) A scenario analysis of future energy systems based on an energy flow model represented as functionals of technology options. Appl Energy 132:586–601

Maes D, Van Dael M, Vanheusden B et al (2015) Assessment of the sustainability guidelines of EU Renewable Energy Directive: the case of biorefineries. J Clean Prod 88:61–70

Mancini L, Benini L, Sala S (2015) Resource footprint of Europe: complementarity of material flow analysis and life cycle assessment for policy support. Environ Sci Policy 54:367–376

Negro V, Ruggeri B, Fino D, Tonini D (2017) Life cycle assessment of orange peel waste management. Resour Conserv Recycl 127:148–158

Papadokonstantakis S, Karka P, Kikuchi Y, Kokossis A (2016) Challenges for model-based life cycle inventories and impact assessment in early to basic process design stages. In: Sustainability in the Design, Synthesis and Analysis of Chemical Engineering Processes. Butteworth-Heinemann, pp 295–326. https://doi.org/10.1016/B978-0-12-802032-6.00013-X

Parajuli R, Knudsen MT, Djomo SN, et al (2017) Environmental life cycle assessment of producing willow, alfalfa and straw from spring barley as feedstocks for bioenergy or biorefinery systems. Sci Total Environ 586:226–240. https://doi.org/10.1016/j.scitotenv.2017.01.207

Portha J-F, Jaubert J-N, Louret S, Pons M-N (2010) Life cycle assessment applied to naphtha catalytic reforming. Oil Gas Sci Technol – Rev d’IFP Energies Nouv 65:793–805. https://doi.org/10.2516/ogst/2010019

ProMax (2019) https://bre.com/. Accessed 20 July 2019

ProSim (2019) http://www.prosim.net/en/index.php. Accessed 20 July 2019

Serra P, Giuntoli J, Agostini A et al (2017) Coupling sorghum biomass and wheat straw to minimise the environmental impact of bioenergy production. J Clean Prod 154:242–254

SimaPro (2019) https://simapro.com/. Accessed 12 Feb 2019

TEAM (2019) https://ecobilan.pwc.fr/en/team.html. Accessed 12 Feb 2019

Thinkstep Gabi (2019) https://www.thinkstep.com/. Accessed 12 Feb 2019

Tonini D, Hamelin L, Astrup TF (2016a) Environmental implications of the use of agro-industrial residues for biorefineries: application of a deterministic model for indirect land-use changes. GCB Bioenergy 8:690–706

Tonini D, Hamelin L, Alvarado-Morales M, Astrup TF (2016b) GHG emission factors for bioelectricity, biomethane, and bioethanol quantified for 24 biomass substrates with consequential life-cycle assessment. Bioresour Technol 208:123–133

Tumilar A, Sharma M, Milani D, Abbas A (2016) Modeling and simulation environments for sustainable low-carbon energy production—a review. Chem Prod Process Model 11:97–124

Turner DA, Williams ID, Kemp S (2016) Combined material flow analysis and life cycle assessment as a support tool for solid waste management decision making. J Clean Prod 129:234–248

Umberto (2019) https://www.ifu.com/en/umberto/lca-software/. Accessed 12 Feb 2019

Vadenbo C, Tonini D, Burg V, et al (2018) Environmental optimization of biomass use for energy under alternative future energy scenarios for Switzerland. Biomass and Bioenergy 119:462–472. https://doi.org/10.1016/j.biombioe.2018.10.001

Wang Q-L, Li W, Gao X, Li S-J (2016) Life cycle assessment on biogas production from straw and its sensitivity analysis. Bioresour Technol 201:208–214

Yoshida H, Nielsen MP, Scheutz C et al (2016) Long-term emission factors for land application of treated organic municipal waste. Environ Model Assess 21:111–124

Zabaniotou A (2018) Redesigning a bioenergy sector in EU in the transition to circular waste-based bioeconomy—a multidisciplinary review. J Clean Prod 177:197–206

Zarrin B, Baumeister H (2014) Design of a domain-specific language for material flow analysis using Microsoft DSL tools. In: Proceedings of the 14th Workshop on Domain-Specific Modeling - DSM ’14. ACM Press, New York, pp 23–28

Acknowledgements

The authors wish to acknowledge funding from the Danish EUDP grant “SustEnergy” (grant no. EUDP 6417-0044).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Responsible editor: Shabbir Gheewala

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(PDF 511 kb)

Rights and permissions

About this article

Cite this article

Lodato, C., Tonini, D., Damgaard, A. et al. A process-oriented life-cycle assessment (LCA) model for environmental and resource-related technologies (EASETECH). Int J Life Cycle Assess 25, 73–88 (2020). https://doi.org/10.1007/s11367-019-01665-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-019-01665-z