Abstract

Purpose

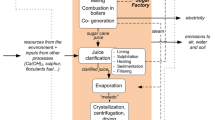

This work generates attributional life cycle assessment (LCA) results for products produced from Australian sugarcane—raw sugar, molasses, electricity (from bagasse combustion), and ethanol (from molasses). It focuses on cane processing in sugar mills and is a companion to the work presented in (Renouf et al. 2010), where the focus is on cane growing. This work also examines the preferred approach for assigning impacts to the multiple products from cane processing, and the influence that variability in cane growing has on the results.

Method

Initially, global warming potentials were generated for a range of cane processing models, using economic allocation (EA), mass allocation (MA), and system expansion (SE). A preferred approach was identified and applied to generate results for a wider set of impact categories based on the Impact 2002+ method. Uncertainty in the results due to cane-growing variability was assessed using Monte Carlo analysis and compared with the results for substitute products to determine the significance of the variability.

Results

While the generation of results using SE was appealing for assessing the determining product (raw sugar), it was found to be less valid for the co-products (molasses, electricity, and ethanol). Results could be generated more consistently across all products using allocation. MA was found to be best suited to sugarcane products, whereas EA posed some problems. The uncertainty due to variability in sugarcane growing was found to be significantly higher than that of substitute products.

Conclusions and recommendations

LCA results for sugarcane products are influenced by (1) the nature of cane processing system, (2) variability in sugarcane growing, and (3) the approach taken for assigning impacts to the multiple products from sugarcane processing. The first two factors imply that results should be specific to the cane-growing region and the cane processing used to produce them. In relation to the latter issue, for generating attributional LCA results that are consistent across all sugarcane products, the recommended approach is to use mass allocation (with energy allocation for bagasse combustion and cogeneration).

Similar content being viewed by others

References

ABARE (2004–2008) Australian commodities data—sugar. Australian Bureau of Agriculture and Resource Economics. www.abare.gov.au.

Andrae ASG (2009) Global life-cycle impact assessment of material shifts: the example of a Pb-free electronics industry. Springer, London

Anon (2006) Australian sugar year book 2006. Rural Press Limited, Brisbane

Beeharry RP (2001) Carbon balance of sugarcane bioenergy systems. Biomass Bioenergy 20:361–370

Beer T, Grant T, Brown R et al (2000) Life cycle emissions analysis of alternative fuels for heavy vehicles CSIRO Atmospheric Research Report to the Australian Greenhouse Office. Report no. C/0411/1.1F2

Botha T, von Blottnitz H (2006) A comparison of the environmental benefits of bagasse-derived electricity and fuel ethanol on a life-cycle basis. Energy Policy 34:2654–2661

Cherubini F, Jungmeier G (2010) LCA of a biorefinery concept producing bioethanol, bioenergy, and chemicals from switchgrass. Int J Life Cycle Assess 15(1):53–66

Contreras AM (2009) Comparative life cycle assessment of four alternatives for using by-products of cane sugar production. J Cleaner Prod 17(8):772–779

DEWHA (2008) National pollutant inventory. Retrieved 6/2/2008, 2008, from www.npi.gov.au

Ekvall T, Weidema BP (2004) System boundaries and input data in consequential life cycle inventory analysis. Int J Life Cycle Assess 9(3):161–171

Ekvall T, Andrae ASG (2006) Attributional and consequential environmental assessment of the shift to lead-free solders. Int J Life Cycle Assess 11(5):344–353

Gopal AR, Kammen DM (2009) Molasses for ethanol: the economic and environmental impacts of a new pathway for the lifecycle greenhouse gas analysis of sugarcane ethanol. Environ Res Lett 4(4):5

Hoefnagels R, Smeets E, Faaij A (2010) Greenhouse gas footprints of different biofuel production systems. Renew Sustain Energy Rev 14(7):1661–1694

International Standards Organisation (2006) Environmental management—life cycle assessment—principles and framework. ISO 14040:2006(E). International Organization for Standardization, Geneva

IPCC (2003) Chapter 6.12 global warming potentials. IPCC third assessment report—climate change 2001. International panel on climate change

Jolliet O, Margni M, Charles R et al (2003) IMPACT 2002+: a new life cycle impact assessment methodology. Int J Life Cycle Assess 8(6):324–330

Jungmeier G, Werner F, Jarnehammar A et al (2002) Allocation in LCA of wood-based products—experiences of cost action E9—part II. Examples. Int J Life Cycle Assess 7(6):369–375

Kadam KL (2002) Environmental benefits on a life cycle basis of using bagasse-derived ethanol as a gasoline oxygenate in India. Energy Policy 30:371–384

Kaufman AS, Meier PJ, Sinistore JC et al (2010) Applying life-cycle assessment to low carbon fuel standards-How allocation choices influence carbon intensity for renewable transportation fuels. Energy Policy 38(9):5229–5241

Khatiwada D, Silveira S (2009) Net energy balance of molasses based ethanol: the case of Nepal. Renew Sustain Energy Rev 13(9):2515–2524

Lavarack BP (2003) Estimates of ethanol production from sugarcane feedstocks. Proceedings of the Australian Society of Sugar Cane Technologists 25

Lavarack B, Hodgson J, Broadfoot R (2005) Prioritising options to reduce the process steam consumptin in raw sugar mills. 25th Congress of the International Society of Sugar Cane Technologists, Guatemala City, Guatemala

Life Cycle Strategies (2007) Australian unit process LCI library and methods. Version 2009.11. November 2009. http://simapro.lifecycles.com.au.

Luo L, van der Voet E, Huppes G (2009a) Life cycle assessment and life cycle costing of bioethanol from sugarcane in Brazil. Renew Sustain Energy Rev 13(6–7):1613–1619

Luo L, van der Voet E, Huppes G et al (2009b) Allocation issues in LCA methodology: a case study of corn stover-based fuel ethanol. Int J Life Cycle Assess 14(6):529–539

Macedo IC, Seabra JEA, Silva JEAR (2008) Greenhouse gases emissions in the production and use of ethanol from sugarcane in Brazil: the 2005/2006 averages and a prediction for 2020. Biomass Bioenergy 32(7):582–595

Manohar Rao PJ (1997) Industrial utilization of sugar cane and its by-products. ISPCK Publishers and Distributors, New Delhi

Miller SA, Landis AE, Theis TL (2007) Environmental trade-offs of biobased production. Environ Sci Technol 41(15):5176–5182

National Greenhouse Gas Inventory Committee (2007) Australian methodology for the estimation of greenhouse gas emissions and sinks 2006: Energy (stationary sources) Australian Government Department of Climate Change, Canberra

Nguyen TLT, Gheewala SH (2008) Life cycle assessment of fuel ethanol from cane molasses in Thailand. Int J Life Cycle Assess 13(4):301–311

Ometto AR, Hauschild MZ, Roma WNL (2009) Lifecycle assessment of fuel ethanol from sugarcane in Brazil. Int J Life Cycle Assess 14(3):236–247

Paturau JM (1989) By-products of the cane sugar industry. An introduction to their industrial utilization. Elsevier Science Publishers, Amsterdam

QDPIF (nd) Broadacre field crop information. Retrieved 6/2/2008, 2008, from www.dpi.qld.gov.au.

Ramjeawon T (2004) Life cycle assessment of cane-sugar on the island of Mauritius. Int J Life Cycle Assess 9(4):254–260

Ramjeawon T (2008) Life cycle assessment of electricity generation from bagasse in Mauritius. J Cleaner Prod 16(16):1727–1734

Renouf MA (2006) LCA of Queensland cane sugar—lessons for the application of LCA to cropping systems in Australia. 5th Australian Conference on Life Cycle Assessment. Australian Life Cycle Assessment Society, Melbourne

Renouf MA, Wegener MK, Pagan R (2010) Life cycle assessment of Australian sugarcane production with a focus on sugarcane growing. Int J Life Cycle Assess 15(9):927–937. doi:10.1007/s11367-010-0226-x

Silalertruksa T, Gheewala SH (2009) Environmental sustainability assessment of bio-ethanol production in Thailand. Energy 34(11):1933–1946

Smeets EMW, Bouwmanw LF, Stehfest E et al (2009) Contribution of N2O to the greenhouse gas balance of first-generation biofuels. Glob Chang Biol 15(1):1–23

Swiss Centre for Life Cycle Inventories (2009) Ecoinvent database. Version 2.0. December 2010. http://www.ecoinvent.ch/

Thomassen MA, Dalgaard R, Heijungs R et al (2008) Attributional and consequential LCA of milk production. Int J Life Cycle Assess 13(4):339–349

von Blottnitz H, Curran MA (2007) A review of assessments conducted on bio-ethanol as a transportation fuel from a net energy, greenhouse gas, and environmental life cycle perspectvie. J Cleaner Prod 15:607–619

Wang M, Wu M, Huo H et al (2008) Life-cycle energy use and greenhouse gas emission implications of Brazilian sugarcane ethanol simulated with the GREET model. Int Sugar J 110(1317):527–545

Acknowledgement

This research was undertaken as part of a PhD project through the School of Geography, Planning and Environmental Management at The University of Queensland. The authors are grateful for the support and funding provided by the Cooperative Research Centre for Sugar Industry Innovation through Biotechnology (CRC SIIB), and for the technical guidance and data contributed by Sugar Research and Innovation at Queensland University of Technology (QUT) and Queensland sugar mills. The authors also acknowledge the very constructive comments received by the anonymous reviewers.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Renouf, M.A., Pagan, R.J. & Wegener, M.K. Life cycle assessment of Australian sugarcane products with a focus on cane processing. Int J Life Cycle Assess 16, 125–137 (2011). https://doi.org/10.1007/s11367-010-0233-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-010-0233-y