Abstract

Goal, Scope and Background

Wood is the most important renewable material. The management of wood appears to be a key action to optimise the use of resources and to reduce the environmental impact associated with mankind’s activities. Wood-based products must be analysed considering the two-fold nature of wood, commonly used as a renewable material or regenerative fuel. Relevant, up-to-date environmental data are needed to allow the analysis of wood-based products. The main focus of this study is to provide comprehensive data of one key wood board industry such as the Medium Density Fibreboard (MDF). Moreover, the influence of factors with strong geographical dependence, such as the electricity profile and final transport of the product, is analysed.

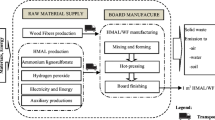

In this work, International Organization for Standardization standards (ISO 14040-43) and Ecoindicator 99 methodology have been considered to quantify the potential environmental impact associated to the system under study. Three factories, considered representative of the ‘state of art’, were selected to study the process in detail: two Spanish factories and a Chilean one, with a process production of around 150,000 m3 per year. The system boundaries included all the activities taking place into the factory as well as the activities linked to the production of the main chemicals used in the process, energy inputs and transport. All the data related to the inputs and outputs of the process were obtained by on-site measurements during a one-year period. A sensitive analysis was carried out taking into account the influence of the final transport of the product and the dependence on the electricity generation profile.

Life Cycle Inventory Analysis

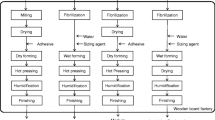

LCI methodology has been used for the quantification of the impacts of the MDF manufacture. The process chain can be subdivided in three main subsystems: wood preparation, board shaping and board finishing. The final transport of the product was studied as a different subsystem, considering scenarios from local to transoceanic distribution and three scenarios of electricity generation profile were assessed. The system was characterised with Ecoindicator 99 methodology (hierarchic version) in order to identify the ‘hot spots’. Damage to Human Health, Ecosystem Quality and Resources are mainly produced by the subsystem of Wood Preparation (91.1%, 94.8% and 94.1%, respectively). The contribution of the subsystem of Board Finishing is considerably lower, but also significant, standing for the 5.8% of the damage to HH and 5.5% of the damage to Resources.

Condusions

With the final aim of creating a database of wood board manufacture, this work was focused in the identification and characterisation of one of the most important wood-based products: Medium Density Fibreboard. Special attention has been paid in the inventory analysis stage of the MDF industry. The results of the sensitive analysis showed a significant influence of both the final transport of the product and the electricity generation profile. Thus, the location of MDF process is of paramount importance, as both aspects have considerable site-dependence.

Recommendations and Perspectives

Research continues to be conducted to identify the environmental burdens associated to the materials of extended use. In this sense, future work can be focused on the comparison of different materials for specific applications.

Similar content being viewed by others

References

Bowyer J (1995): Wood and other raw materials for the 21st century. Forest Prod J 45(2) 17–24

Skodras G, Grammelies P, Kakaras E, Sakellaropoulos GP (2004): Evaluation of the environmental impact of waste wood co-utilisation for energy production. Energy 29, 2181–2193

Petersen AK, Solberg B (2005): Environmental and economic impacts of substitution between wood products and alternative materials: a review of micro-level analyses from Norway and Sweden. Forest Policy Econ 7(3) 249–259

Stael GC, Tavares MIB, d’Almeida JRM (2001): Impact behaviour of sugarcane bagasse waste-EVA composites. Polymer Testing 20, 869–872

UNECE/FAO Forest Products. Annual Market Review 2003–2004 Timber Bulletin Volume LVII (2004), No. 3

Koziński J, Saade R (1998): Effect of biomass burning on the formation of soot particles and heavy hydrocarbons. An experimental study. Fuel 77(4) 225–237

Baumann H, Tillman AM (2004): The Hitch Hiker’s Guide to LCA. An Orientation in Life Cycle Assessment Methodology and Application. ISBN 9144023642, Studentlitteratur, Lund, Sweden, 543 pp

Jungmeier G, Werner F, Jarnehammar A, Hohenthal C, Richter K (2002): Allocation in LCA of Wood-based Products. Experiences of Cost Action E9. Part I. Methodology. Int J LCA 7(5) 290–294

Jungmeier G, Werner F, Jarnehammar A, Hohenthal C, Richter K (2002): Allocation in LCA of Wood-based Products. Experiences of Cost Action E9. Part II. Examples. Int J LCA 7(6) 369–375

Berg S, Lindholm EL (2005): Energy use and environmental impacts of forest operations in Sweden. J Cleaner Prod 13, 33–42

Berg S (1997): Some aspects of LCA in the analysis of forestry operations. J Cleaner Prod 5, 211–217

Aldentun Y (2002): Life cycle inventory of forest seedling production — From seed to regeneration site. J Cleaner Prod 10, 47–55

Rivela B, Hospido A, Moreira MT, Feijoo G (2006): Life Cycle Inventory of Particle board: A Case Study in the Wood Sector. Int J LCA 11(2) 106–223

ISO 14040 (1997): Environmental management — Life cycle assessment — Principles and framework

U.S. Environmental Protection Agency (2002): Emission Factor Documentation for AP — 42, Fifth Edition, Volume I, Chapter 10: Wood Products Industry, Section 10.6.3: Medium Density Fiberboard Manufacturing: Final Report, 〈http://www.epa.gov/ttn/chief/ap42/ch10/related/c10s0603.html〉

IDEMAT database (2001): Faculty of Industrial Design Engineering of Delft University of Technology, The Netherlands

Frischknecht R (final ed), Bollens U, Bosshart S, Ciot M, Ciseri L, Doka G, Hischier R, Martin A, Dones R, Gantner U (1996): ETH-ESU 96, Ökoinventare von Energiesystemen, Grundlagen für den okologischen Vergleich von Energiesystemen und den Einbezug von Energiesystemen in Ökobilanzen für die Schweiz (German language only), 3rd Edition, ETH Zurich, Switzerland

BUWAL 250 (1996): Ökoinventare für Verpackungen. Schriftenreihe Umwelt 250, Bern, Switzerland

Werner F, Richter K, Bosshart S, Frischknecht R (1997): Ökologischer Vergleich von Innenbauteilen am Bsp. Von Zargen aus Massivholz, Holzwerkstoff und Stalhl (Ecological comparison for indoor building materials — Comparison of frames made by solid wood, fibre wood and steel), EMPA/ETH-Forschungsbericht, Dübendorf, Zurich, Switzerland

Nebel B, Zimmer B, Wegener Z (2006): Life Cycle Assessment of Wood Floor Coverings. A Representative Study for the German Flooring Industry. Int J LCA 11(3) 172–182

Jungmeier G, McDarby F, Evald A, Hohenthal C, Petersen AK, Schawaiger HP, Zimmer B (2003): Energy Aspects in LCA of Forest Products: Guidelines from Cost Action E9. Int J LCA 8(2) 99–105

Goedkoop M, Spriensma R (2000): The eco-indicator 99 — A damage oriented method for life cycle impact assessment. Methodology report, Pré Consultants BV, The Netherlands

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rivela, B., Moreira, M.T. & Feijoo, G. Life cycle inventory of medium density fibreboard. Int J Life Cycle Assess 12, 143–150 (2007). https://doi.org/10.1065/lca2006.12.290

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1065/lca2006.12.290