Abstract

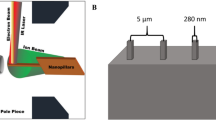

Tristructural-isotropic (TRISO) fuel particles are being investigated as a potential fuel for both current and advanced reactors. Due to the size of the particles (<1 mm in diameter with a silicon carbide layer thickness of 30–50 μm), traditional mechanical testing is a challenge, and investigations are limited to micro-scale mechanical testing techniques. In the work presented here, ring crush tests of TRISO particles were performed, and the results are compared with nanoindentation measurements of particles from the same manufactured batch. The elastic modulus results from the nanoindentation and the ring crush tests are found to be in good agreement. In addition, an innovative technique for studying helium implantation effects on the material was investigated utilizing an ORION NanoFab Helium Ion Microscope.

Similar content being viewed by others

References

Hosemann P, Martos JN, Frazer D, Vasudevamurthy G, Byun TS, Hunn JD, Jolly BC, Terrani K, Okuniewski M (2013) Mechanical characteristics of SiC coating layer in TRISO fuel particles. J Nucl Mater 442:133–142

Rohbeck N, Tsivoulas D, Shapiro IP, Xiao P, Knol S, Escleine J-M, Perez M (2015) In-situ nanoindentation of irradiated silicon carbide in TRISO particle fuel up to 500°C. J Nucl Mater 465:692–694

Tan J, Meadows PJ, Zhang D, Xi C, Lopez-Honorato E, Zhao X, Yang F, Abram T, Xiao P (2009) Young’s modulus measurements of SiC coatings on spherical particles by using nanoindentation. J Nucl Mater 393:22–29

Kim W-J, Park JN, Cho MS, Park JY (2009) Effect of coating temperature on properties of the SiC layer in TRISO-coated particles. J Nucl Mater

Frazer D, Abad MD, Krumwiede D, Back CA, Khalifa HE, Deck CP, Hosemann P (2015) Localized mechanical property assessment of SiC/SiC composite materials. Compos A: Appl Sci Manuf 70:93–101

Katoh Y, Ozawa K, Shih C, Nozawa T, Shinavski RJ, Hasegawa A, Snead LL (2014) Continuous SiC fiber, CVI SiC matrix composites for nuclear applications: properties and irradiation effects. J Nucl Mater 448:448–476

Stone JG, Schleicher R, Deck CP, Jacobsen GM, Khalifa HE, Back CA (2015) Stress analysis and probabilistic assessment of multi-layer SiC-based accident tolerant nuclear fuel cladding. J Nucl Mater 466:682–697

Snead LL, Nozawa T, Katoh Y, Byun TS, Kondo S, Petti DA (2007) Handbook of SiC properties for fuel performance modeling. J Nucl Mater 371:329–377

Nickel H, Nabielek H, Pott G, Mehner AW (2007) Long time experience with the development of HTR fuel elements in Germany. Nucl Eng Des 217:141–151

Meyer MK, Fielding R, Gan J (2007) Fuel development for gas-cooled fast reactors. J Nucl Mater 371:281–287

Kim WJ, Kim D, Park JY (2013) Fabrication and material issues for the application of SiC composites to LWR fuel cladding. Nucl Eng Technol 45:565–572

Deck CP, Jacobsen GM, Sheeder J, Gutierrez O, Zhang J, Stone J, Khalifa HE, Back CA (2015) Characterization of SiC-SiC composites for accident tolerant fuel cladding. J Nucl Mater 466:667–681

Snead LL, Nozawa T, Ferraris M, Katoh Y, Shinavski R, Sawan M (2011) Silicon carbide composites as fusion power reactor structural materials. J Nucl Mater 417:330–339

Saito S, Tanaka T, Sudo Y, Baba O, Shindo M, Shiozawa S, Kobayashi F, Kurihara R, Hada K, Yamashita K, Kawasaki K, Iyoku T, Kunitomi K, Maruyama S (1994) Design of High Temperature Test Reactor (HTTR), JAERI-1332, Japan Atomic Energy Research Institute

Terrani KA, Snead LL, Gehin JC (2012) Microencapsulated fuel technology for commercial light water and advanced reactor application. J Nucl Mater 427:209–224

Mills P, Soto R, Gibbs G (2007) Next generation nuclear plant pre-conceptual Design report, (INL/EXT-07-12967, Idaho National Laboratory, Idaho Falls, ID)

Forsberg CW, Peterson PF, Pickard P (2003) Molten-salt-cooled advanced high-temperature reactor for production of hydrogen and electricity. Nucl Technol 144:289–302

Forsberg CW, Peterson PF, Zhao H (2006) Sustainability and economics of the advanced high-temperature reactor. J Energy Eng 132:109–115

International Atomic Energy Agency (1997) Fuel performance and fission product behavior in gas cooled reactors, IAEA-TECDOC-978. IAEA, Vienna

Silady FA, Parme LL (1989) The safety approach of the modular high temperature gas cooled reactor (MHTGR). 11th International Conference on the HTGR, Dimitrovgrad

Powers J, Wirth B (2010) A review of TRISO fuel performance models. J Nucl Mater 405:74–82

Morris RN, Petti DA, Power DA, Boyack BE, Rubin MB (2004) TRISO-Coated Particle Fuel Phenomenon Identification and Ranking Tables (PIRTs) for Fission Product Transport Due to Manufacturing, Operations, and Accidents: Main Report, (NUREG/CR-6844, Volume 1)

Riccardi B, Giancarli L, Hasegawa A, Katoh Y, Kohyama A, Jones RH, Snead LL (2004) Issues and advances in SiCf/SiC composites development for fusion reactors. J Nucl Mater 329–333:56–65

Li BS, Du YY, Wang ZG, Wei KF, Zhang HP, Yao CF, Chang HL, Sun JR, Cui MH, Sheng YB, Pang LL, Zhu YB, Gao X, Luo P, Zhu HP, Wang J, Wang D (2015) Transmission electron microscopy investigations of bubble formation in he-implanted polycrystalline SiC. Vacuum 113:75–83

Snead LL, Zinkle SJ Threshold irradiation dose for amorphization of silicon carbide. Oak Ridge National Laboratory.

Li BS, Wang ZG, Zhang CH, Wei KF, Yao CF, Sun JR, Cui MH, Li YF, Zhu HP, Du YY, Zhu YB, Pang LL, Song P, Wang J (2014) Evolution of strain and mechanical properties upon annealing in he-implanted 6H-SiC. J Nucl Mater 455:116–121

Beaufort MF, Pailloux F, Declemy A, Barbot JF (2003) Transmission electron microscopy investigations of damage induced by high energy helium implantation in 4H–SiC. J Appl Phys 94:7116

Kralik V, Nemecek J (2014) Comparison of nanoindentation techniques for local mechanical quantification of aluminum alloy. Mater Sic Eng A 618:118–128

Zhao X, Langford RM, Tan J, Xiao P (2008) Mechanical properties of SiC coatings on spherical particles measured using the micro-beam method. Scr Mater 59:39–42

Di Maio D, Roberts SG (2005) Measuring fracture toughness of coatings using focused-ion-beam-machined microbeams. J Mater Res 20:299–302

Lopez-Honorato E, Meadows PJ, Tan J, Xiao P (2008) Control of stoichiometry, microstructure, and mechanical properties in SiC coatings produced by fluidized bed chemical vapor deposition. J Mater Res 23:1785–1796

Zhang H, López-Honorato E, Javed A, Shapiro I, Xiao P (2012) A study of the microstructure and vickers indentation fracture toughness of silicon carbide coatings on triso fuel particles. J Am Ceram Soc 95:1086–1092

van Gastel R, Barriss L, Sanford C, Hlawacek G, Scipioni L, Merkle AP, Voci D, Fenner C, Zandvliet HJW, Poelsema B (2011) Design and performance of a near ultra high vacuum helium ion microscope. Microsc Microanal 17(S2):928–929

Veligura V, Hlawacek G, Berkelaar RP, Gaste RV, Zandvliet HJW, Poelsema B (2013) Digging gold: keV He+ ion interact.tion with Au. Beilstein J. Nanotechnol 4:453–460

Ogbuji LUJT, Opila EJ (1995) A comparison of the oxidation kinetics of SiC and Si3 N 4. J Electrochem Soc 142(3):925–930

Bongartz K, Gyarmati E, Schuster H, Tauber K (1976) Brittle ring test – method for measuring strength and Youngs modulus on coatings of Htr fuel particles. J Nucl Mater 62:123–137

Timosohenko S (1956) Strength of Materials Part 1, 2nd. Van Nostrand Co, New York, pp 365, 369, 387, 388

Bongartz K, Gyarmati E, Nickel H, Schuster H, Winter W (1972/73) Measurement of Young’s modulus and fracture stress on HTR particle coatings by the brittle ring test. J Nucl Mater 45:261–264

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7:1564–1583

Ziegler JR et al (2006) SRIM – The Stopping and Range of Ions in Matter. http://www.srim.org/

Minato K, Fukuda K, Ikawa K (1982) Strength of silicon-carbide coating layers of fuel particles for high temperature gas-cooled reactors. J Nucl Sci Technol 19(1):69–77

Acknowledgements

The authors would like to thank Dr. Frances Allen for assistance with the ORION NanoFab and for helpful comments on the manuscript. In addition, the authors would like to thank the BNC at UC Berkeley for the use of the ORION NanoFab instrument. The ORION nanofab was funded through the NSF-MRI grant #1338139.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Frazer, D., Szornel, J., Krumwiede, D.L. et al. Evaluation of the Mechanical Properties of TRISO Particles Using Nanoindentation and Ring Compression Testing. Exp Mech 57, 1081–1090 (2017). https://doi.org/10.1007/s11340-017-0277-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-017-0277-z