Abstract

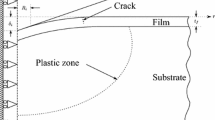

Mechanical properties of a hard and stiff W-C coating on steel substrate have been investigated using nanoindentation combined with finite element modeling (FEM) and extended FEM (XFEM). The significant pile-up observed around the indents in steel substrate caused an overestimation of hardness and indentation modulus. A simple geometrical model, considering the additional contact surfaces due to pile-up, has been proposed to reduce this overestimation. The presence of W-C coating suppressed the pile-up in the steel substrate and a transition to sink-in behavior occurred. The FEM simulations adequately reproduced the surface topography of the indents in the substrate and coating/substrate systems as well. The maximum principal stresses of the indented W-C/steel coated system were tensile; they were always located in the coating and evolved in 3 stages. Cohesive cracking occurred during loading in the sink-in zone (stage III) when the ultimate tensile strength (σ max ) of the coating was reached. The obtained hardness (H c ), indentation modulus (E c ), yield stress (Y) and strength (σ max ) of the W-C coating were H c = 20 GPa, E c = 250 GPa, Y = 9.0 GPa and σ max = 9.35 GPa, respectively. XFEM resulted in fracture energy of the W-C coating of G = 38.1 J · m-2 and fracture toughness of K IC = 3.5 MPa · m0.5.

Similar content being viewed by others

References

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic using load and displacement sensing indentation experiments. J Mater Res 7:1564–1583

Bückle H (1973) In: Westbrook JW, Conrad H (eds) The science of hardness testing and its applications. Amer Soc Metals, Metals Park, pp 453–491

Jőnsson B, Hogmark S (1984) Hardness measurement of thin films. Thin Solid Films 114:257–269

Iost A, Bigot R (1996) Hardness of coatings. Suf Coat Technol 80:117–120

Korsunsky AM, McGurk MR, Bull SJ, Page TF (1998) On the hardness of coated systems. Surf Coat Technol 99:171–183

Saha R, Nix WD (2001) Soft films on hard substrates—nanoindentation of tungsten films on sapphire substrates. Mater Sci Eng A 319–321:898–901

Saha R, Nix WD (2002) Effects of the substrate on the determination of thin film mechanical properties by nanoindentation. Acta Mater 50:23–38

Beegan D, Chowdhury S, Laugier MT (2004) The nanoindentation behaviour of hard and soft films on silicon substrates. Thin Solid Films 466:167–174

Jung YG, Lawn BR, Martyniuk M, Huang H, Hu XZ (2004) Evaluation of elastic modulus and hardness of thin films by nanoindentation. J Mater Res 19:3076–3080

Zyganitidis I, Kalfagiannis N, Logothetidis S (2009) Ultra sharp Berkovich indenter used for nanoindentation studies of TiB2 thin films. Mater Sci Eng B 165:198–201

Iost A, Guillemot G, Rudermann Y, Bigerelle M (2012) A comparison of the models for predicting the true hardness of thin films. Thin Solid Films 524:229–237

Chen J, Bull S (2009) On the factors affecting the critical indenter penetration for measurement of coating hardness. Vacuum 83:911–920

ISO 14577-4 (2007) Metallic materials- Instrumented indentation test for hardness and materials parameters—part 4 Test method for metallic and non-metallic coatings

Cai X, Bangert H (1995) Hardness measurement on thin films—determining the critical ratio of depth to thickness using FEM. Thin Solid Films 264:59–71

Kataria S, Goyal S, Dash S, Sandhya R, Mathew MT, Tyagi AK (2012) Evaluation of nano-mechanical properties of hard coatings on a soft substrate. Thin Solid Films 522:297–303

Bouzakis KD, Michailidis N, Hadjiyiannis S, Skordaris G, Erkens G (2003) The effect of specimen roughness and indenter tip geometry on the determination accuracy of thin hard coating stress-strain laws by nanoindentation. Mat Character 49:149–156

Jiang WG, Su JJ, Feng XQ (2008) Effect of surface roughness on nanoindentation test of thin films. Eng Fracture Mech 75:4965–4972

Bolshakov A, Pharr GM (1998) Influences of pileup on the measurement of mechanical properties by load and depth sensing indentation techniques. J Mater Res 13:1049–1058

Moharrami N, Bull SJ (2014) A comparison of nanoindentation pile-up in bulk materials and thin films. Thin Solid Films 572:189–199

Bull SJ, Rickerby DS (1990) New developments in the modelling of the hardness and scratch adhesion of thin films. Surf Coat Technol 42:149–164

Suresh S, Giannakopoulos AE (1998) A new method for estimating residual stresses by instrumented sharp indentation. Acta Mater 46:5755–5767

Li X, Bhushan B (2000) Development of continuous stiffness measurement technique for composite magnetic tapes. Scripta Mater 42:929–935

Li X, Bhushan B (2002) A review of nanoindentation continuous stiffness measurement technique and its applications. Mater Character 48:11–36

Bull SJ, Korsunsky AM (1998) Mechanical properties of thin carbon overcoats. Tribol Int 31:547–551

Puchi-Cabrera ES (2002) A new model for the computation of composite hardness of coated systems. Surf Coat Technol 160:177–186

Menčík J, Munz D, Quandt E, Weppelmann ER, Swain MV (1997) Determination of elastic modulus of thin layers using nanoindentation. J Mater Res 12:2475–2484

Bobji MS, Biswas SK (1999) Deconvolution of hardness from data obtained from nanoindentation of rough surfaces. J Mater Res 14:2259–2268

Bhattacharya AK, Nix WD (1988) Finite element simulations of indentation experiments. Int J Solid Struct 24:881–891

Lichinchi M, Lenardi C, Haupt J, Vitali R (1998) Simulation of Berkovich nanoindentation experiments on thin films using finite element method. Thin Solid Films 312:240–248

Bressan JD, Tramontin A, Rosa C (2005) Modeling of nanoindentation of bulk and thin film by finite element method. Wear 258:0115–0122

Pelegri AA, Huang X (2008) Nanoindentation on soft film/hard substrate and hard film/soft substrate material systems with finite element analysis. Compos Sci Technol 68:147–155

Liu S, Huang H, Gu Y (2012) Deconvolution of mechanical properties of thin films from nanoindentation measurement via finite element optimization. Thin Solid Films 526:183–190

MacKerle J (2005) Coatings and surface modification technologies: a finite element bibliography (1995-2005) Modelling and Simulation. Mater Sci Eng 13:935–979

Fukumasu NK, Souza RM (2014) Numerical evaluation of cohesive and adhesive failure modes during the indentation of coated systems with compliant substrates. Surf Coat Technol 260:266–271

Burnett PJ, Rickerby DS (1987) The mechanical properties of wear-resistant coatings: I: modelling of hardness behaviour. Thin Solid Films 154:403–416

Tsui TY, Oliver WC, Pharr GM (1996) Influences of stress on the measurement of mechanical properties using nanoindentation: part I. experimental studies in an aluminum alloy. J Mater Res 11:752–759

McElhaney KW, Vlassak JJ, Nix WD (1998) Determination of indenter tip geometry and indentation contact area for depth-sensing indentation experiments. J Mater Res 13:1300–1306

Giannakopoulos AE, Suresh S (1999) Determination of elastoplastic properties by instrumented sharp indentation. Scripta Mater 40:1191–1198

Kese K, Li ZC, (2006) Semi-ellipse method for accounting for the pile-up contact area during nanoindentation with the Berkovich indenter. 55:699–702

Zhou X, Jiang Z, Wang H, Yu R (2008) Investigation on methods for dealing with pile-up errors in evaluating the mechanical properties of thin metal films at sub-micron scale on hard substrates by nanoindentation technique. Mater Sci Eng A 488:318–332

Sullivan M, Prorok BC (2016) Evaluating pile-up and sink-in during nanoindentation of thin films. Conf Proc Soc Exp Mech Ser, MEMS Nanotechnol 5:45–50

Bo Z, Prorok BC (2010) A new paradigm in thin film indentation. 25:1671–1678

Zhang S, Sun D, Fu Y, Du H (2005) Toughness measurement of thin films: a critical review. Surf Coat Technol 198:74–84

Malzbender J, de Witt G (2002) A model to determine the interfacial fracture toughness for chipped coatings. Surf Coat Technol 154:21–26

Chen J, Bull SJ (2009) Finite element analysis of contact induced adhesion failure in multilayer coatings with weak interfaces. Thin Solid Films 517:3704–3711

Chen J (2012) On the determination of coating toughness during nanoindentation. Surf Coat Technol 206:3064–3068

Wang AN, Yu PG, Huang JH (2014) Fracture toughness measurement on TiN hard coatings using internal energy induced cracking. Surf Coat Technol 239:20–27

Dugdale DS (1960) Yielding of steel sheets containing slits. J Mech Phys Solids 8:100–104

Barenblatt GI (1962) The mathematical theory of equilibrium cracks in brittle fracture. In: Advances in Applied Mechanics. Academic, NY, pp 55–129

Hu J, Chou YK, Thompson RG (2003) Cohesive zone effect on coating failure evaluations of diamond-coated tools. Surf Coat Technol 203:730–735

Rehman H, Ahmed F, Schmid C, Schaufler J, Durst K (2012) Study on the deformation mechanics of hard brittle coatings on ductile substrates using in-situ tensile testing and cohesive zone FEM modeling. Surf Coat Technol 207:163–169

Huang R, Sukumar N, Prévost J-H (2003) Modeling quasi-static crack growth with the extended finite element method. part ii: numerical applications. Int J Solids Struct 40:7539–7552

Kot M, Rakowski W, Lackner JM, Major T (2013) Analysis of spherical indentations of coating-substrate systems: experiments and finite element modeling. Mater Des 43:99–111

Palmquist JP, Czigany Z, Odén M, Neidhardt J, Hultman L, Jansson U (2003) Magnetron sputtered W-C films with C60 as carbon source. Thin Solid Films 444:29–37

Czyzniewski A (2003) Deposition and some properties of nanocrystalline WC and nanocomposite WC/a-C:H coatings. Thin Solid Films 433:180–185

Abdelouahdi K, Sant C, Legrand-Buscema C, Aubert P, Perrière J, Renou G, Houdy P (2006) Microstructural and mechanical investigations of tungsten carbide films deposited by reactive RF sputtering. Surf Coat Technol 200:6469–6473

Abad MD, Muñoz-Márquez MA, El Mrabet S, Justo A, Sánchez-López JC (2010) Tailored synthesis of nanostructured WC/a-C coatings by dual magnetron sputtering. Surf Coat Technol 204:3490–3500

Lofaj F, Ferdinandy M, Cempura G, Dusza J (2012) Nanoindentation, AFM and tribological properties of thin nc-WC/a-C coatings. J. Eur Ceram Soc 32:2043–2051

Hviščová P, Kvetková L, Lofaj F, Novák M, Ferdinandy M, Podoba R (2015) Mechanical and tribological properties of HiPIMS and HiTUS W-C based coatings. Key Eng Mater 662:99–102

Klein CA (1992) Anisotropy of Young’s modulus and Poisson’s ratio in diamond. Mat Res Bull 27:1407–1414

Oliver WC, Pharr GM (2004) Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology. J Mater Res 19:3–20

Suetin DV, Shein IR, Ivanowskii AL (2008) Elastic and electronic properties of hexagonal and cubic polymorphs of tungsten monocarbide WC and mononitride WN from first principle calculations. Phys Stat Sol b 425:1590–1597

Bucaille JL, Stauss S, Felder E, Michler J (2003) Determination of plastic properties of metals by instrumented indentation using different sharp indenters. Acta Mater 51:1663–1678

Stolarska M, Chopp DL, Moës N, Belytschko T (2001) Modeling crack growth by level sets in the extended finite element method. Int J Numer Meth Eng 51:943–960

Sukumar N, Prévost J-H (2003) Modeling quasi-static crack growth with the extended finite element method. part I. computer implementation. Int J Solids Struct 40:7512–7537

Lee JH, Gao ZF, Johanns KE, Pharr GM (2012) Cohesive interface simulations of indentation cracking as a fracture toughness measurement method for brittle materials. Acta Mater 60:5448–5467

Yu N, Polycarpou AA, Conry TF (2004) Tip-radius effect in finite element modeling of sub-50 nm shallow nanoindentation. Thin Solid Films 450:295–303

Takahashi T, Freise EJ (1965) Determination of the slip systems in single crystals of tungsten monocarbide. Philos Mag 12:1–8

French DN, Thomas DA (1965) Hardness anisotropy and slip in WC crystals. Trans Metal Soc AIME 233:950–952

Cuadrado N et al (2011) Effect of crystal anisotropy on the mechanical properties of WC embedded in WC-Co cemented carbides. Euro PM-Hard Mater 1:215–220

Roebuck B, Klose P, Mingard KP (2012) Hardness of hexagonal tungsten carbide crystals as a function of orientation. Acta Mater 60:6131–6143

Duszová A, Halgaš R, Bľanda M, Hvizdoš P, Lofaj F, Dusza J, Morgiel J (2013) Nanoindentation of WC-Co hardmetals. J Eur Ceram Soc 33:2227–2232

Csanádi T, Bľanda M, Chinh NQ, Hvizdoš P, Dusza J (2015) Orientation-dependent hardness and nanoindentation-induced deformation mechanisms of WC crystals. Acta Mater 83:397–407

Harris JW, Stocker H (1998) Segment of a circle. In: Handbook of mathematics and computational science. Springer, New York, pp 92–93

Zhu L-N, Xu B-S, Wang H-D, Wang C-B (2010) Determination of hardness of plasma-sprayed FeCrBSi coating on steel substrate by nanoindentation. Mater Sci Eng A 528:425–428

Tabor D (1970) The hardness of solids. Rev Phys Technol 1:145–179

Csanádi T et al (2014) Deformation characteristics of WC micropillars. J Eur Ceram Soc 34:4099–4103

Chai H, Lawn BR (2004) Fracture mode transitions in brittle coatings on compliant substrates as a function of thickness. J Mater Res 19:1752–1761

Acknowledgments

The financial support provided by the projects “Research Centre of Advanced Materials and Technologies for Recent and Future Applications” PROMATECH, ITMS project code: 26220220186, and projects APVV-14-0173, VEGA 2/0098/14 and VEGA 2/0187/15 is kindly acknowledged. The assistance of Petra Hviščová with coating deposition is appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Csanádi, T., Németh, D. & Lofaj, F. Mechanical Properties of Hard W-C Coating on Steel Substrate Deduced from Nanoindentation and Finite Element Modeling. Exp Mech 57, 1057–1069 (2017). https://doi.org/10.1007/s11340-016-0190-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-016-0190-x