Abstract

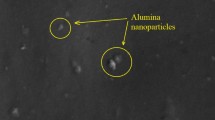

In this study, GLAREs (Glass Reinforced Aluminum Laminates) with 3/2 configuration were fabricated in-house with multi-walled carbon nanotubes (MWCNTs) modified epoxy resins. Uniform dispersion of MWCNTs in epoxy resin was achieved via a two-step dispersion method with concentration up to 2.0 wt%. The influence of MWCNTs on the flexural property and the impact performance of GLAREs was investigated through the three-point bending and drop weight Dynatup impact testings, respectively. The incorporation of MWCNTs into epoxy evidently improved the flexural strength and modulus. In comparison with pure epoxy bonded GLARE, the modified GLAREs generally showed improvement of impact resistance. The improvement was more obvious at low concentration of MWCNT due to better dispersion of nanotubes in the resin and reasonable wettability of glass fibres and aluminium to the modified resin. Diversified failure mechanisms including plastic deformation and rupture of metal layers, breakage of fibres and matrix, delamination between composite and metal layers, and delamination between composite plies were observed. In addition, debonding, pull-out, and bridging effects of carbon nanotubes were observed, which proved the contribution of MWCNTs to the improved impact resistance of the modified GLAREs.

Similar content being viewed by others

References

Vogelesang LB, Vlot A (2000) Development of fibre metal laminates for advanced aerospace structures. J Mater Process Tech 103(1):1–5

Vlot A (2001) Glare: History of the development of a new aircraft material. Kluwer Academic Publishers, Dordrecht

Alderliesten RC, Homan JJ (2006) Fatigue and damage tolerance issues of Glare in aircraft structures. Int J Fatigue 28(10):1116–1123

Vlot A, Vogelesang LB, de Vries TJ (1999) Towards application of fibre metal laminates in large aircraft. Aircr Eng Aerosp Tec 71(6):558–570

Wu GC, Yang JM (2005) The mechanical behavior of GLARE laminates for aircraft structures. JOM 57(1):72–79

de Vries TJ, Vlot A, Hashagen F (1999) Delamination behavior of spliced fiber metal laminates. Part 1. Experimental results. Compos Struct 46(2):131–145

Vlot A (1993) Impact properties of fiber metal laminates. Compos Eng 3(10):911–927

Lawcock G, Ye L, Mai YW, Sun CT (1997) The effect of adhesive bonding between aluminum and composite prepreg on the mechanical properties of carbon-fiber-reinforced metal laminates. Compos Sci Technol 57(1):35–45

Lawcock GD, Ye L, Mai YW, Sun CT (1997) Effects of fibre/matrix adhesion on carbon-fibre-reinforced metal laminates - II. Impact behaviour. Compos Sci Technol 57(12):1621–1628

Vlot A, Krull M (1997) Impact damage resistance of various fibre metal laminates. J Phys IV 7(C3):1045–1050

Yaghoubi AS, Liu Y, Liaw B (2012) Stacking sequence and geometrical effects on low-velocity impact behaviors of GLARE 5 (3/2) fiber-metal laminates. J Thermoplast Compos 25(2):223–247

Moriniere FD, Alderliesten RC, Benedictus R (2012) Development of fibre-metal laminates for improved impact performance. Eur Phys J-Spec Top 206(1):79–88

Suhr J, Koratkar NA (2008) Energy dissipation in carbon nanotube composites: a review. J Mater Sci 43(13):4370–4382

Koratkar NA, Suhr J, Joshi A, Kane RS, Schadler LS, Ajayan PM, Bartolucci S (2005) Characterizing energy dissipation in single-walled carbon nanotube polycarbonate composites. Appl Phys Lett 87(6):063102

Alhazov D, Zussman E (2012) Study of the energy absorption capabilities of laminated glass using carbon nanotubes. Compos Sci Technol 72(6):681–687

Tang LC, Zhang H, Wu XP, Zhang Z (2011) A novel failure analysis of multi-walled carbon nanotubes in epoxy matrix. Polymer 52(9):2070–2074

ASTM D2651–01 (2008) Standard guide for preparation of metal surfaces for adhesive bonding. ASTM international, Pennsylvania

Prolongo SG, Urena A (2009) Effect of surface pre-treatment on the adhesive strength of epoxy-aluminium joints. Int J Adhes Adhes 29(1):23–31

Caprino G, Spataro G, Del Luongo S (2004) Low-velocity impact behaviour of fibreglass-aluminium laminates. Compos Part A-Appl S 35(5):605–616

Zhai LL, Ling G, Wang YW (2008) Effect of nano-Al2O3 on adhesion strength of epoxy adhesive and steel. Int J Adhes Adhes 28(1–2):23–28

Meguid SA, Sun Y (2004) On the tensile and shear strength of nano-reinforced composite interfaces. Mater Design 25(4):289–296

Dorigato A, Morandi S, Pegoretti A (2012) Effect of nanoclay addition on the fiber/matrix adhesion in epoxy/glass composites. J Compos Mater 46(12):1439–1451

Xu Y, Van Hoa S (2008) Mechanical properties of carbon fiber reinforced epoxy/clay nanocomposites. Compos Sci Technol 68(3–4):854–861

Vlasveld DPN, Daud W, Bersee HEN, Picken SJ (2007) Continuous fibre composites with a nanocomposite matrix: improvement of flexural and compressive strength at elevated temperatures. Compos Part A-Appl S 38(3):730–738

Ogasawara T, Ishida Y, Ishikawa T (2004) Properties of vapor grown carbon nano fiber/phenylethynyl terminated polyimide composite. Adv Compos Mater 13(3–4):215–226

Prolongo SG, Gude MR, Urena A (2010) Rheological behaviour of nanoreinforced epoxy adhesives of low electrical resistivity for joining carbon fiber/epoxy laminates. J Adhes Sci Technol 24(6):1097–1112

Qian D, Dickey EC, Andrews R, Rantell T (2000) Load transfer and deformation mechanisms in carbon nanotube-polystyrene composites. Appl Phys Lett 76(20):2868–2870

Liu TX, Phang IY, Shen L, Chow SY, Zhang WD (2004) Morphology and mechanical properties of multiwalled carbon nanotubes reinforced nylon-6 composites. Macromolecules 37(19):7214–7222

Thostenson ET, Ren ZF, Chou TW (2001) Advances in the science and technology of carbon nanotubes and their composites: a review. Compos Sci Technol 61(13):1899–1912

Hsiao KT, Alms J, Advani SG (2003) Use of epoxy/multiwalled carbon nanotubes as adhesives to join graphite fibre reinforced polymer composites. Nanotechnology 14(7):791–793

Gojny FH, Wichmann MHG, Fiedler B, Bauhofer W, Schulte K (2005) Influence of nano-modification on the mechanical and electrical properties of conventional fibre-reinforced composites. Compos Part A-Appl S 36(11):1525–1535

Fereidoon A, Kordani N, Rostamiyan Y, Ganji DD, Ahangari MG (2010) Effect of carbon nanotubes on adhesion strength of e-glass/epoxy composites and alloy aluminium surface. World Appl Sci J 9(2):204–210

Vlot A (1996) Impact loading on fibre metal laminates. Int J Impact Eng 18(3):291–307

Sadighi M, Alderliesten RC, Benedictus R (2012) Impact resistance of fiber-metal laminates: a review. Int J Impact Eng 49:77–90

Liu Y, Liaw B (2004) Drop-weight impact on fiber-metal laminates using various indenters. In SEM X International Congress and Exposition on Experimental and Applied Mechanics. Costa Mesa, CA

Cortes P, Cantwell WJ (2007) The impact properties of high-temperature fiber-metal laminates. J Compos Mater 41(5):613–632

Acknowledgement

Yang acknowledges the financial support from NTU-SUG grant and is grateful to the insightful discussion in the International Symposium of the Dynamic Behaviors of Materials and Structures held on 26–29 June 2012 in Ningbo, China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, H., Gn, S.W., An, J. et al. Impact Behaviour of GLAREs with MWCNT Modified Epoxy Resins. Exp Mech 54, 83–93 (2014). https://doi.org/10.1007/s11340-013-9724-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-013-9724-7