Abstract

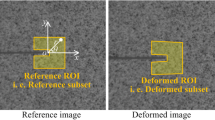

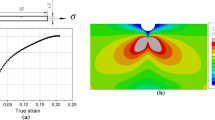

Digital Image Correlation is used for controlling load shedding fatigue crack propagation. A specific algorithm is used to perform Stress Intensity Factors (SIFs) and crack length estimation in real time. Crack length measurements are validated by comparison with potential drop technique. SIFs results are compared with more common techniques using standard analytical formula considering confined plasticity at the crack tip. The proposed non-contact method is shown to be a powerful tool to control crack propagation.

Similar content being viewed by others

References

Bui H (2006) Fracture mechanics: inverse problems and solutions. Springer Verlag

Bathias C, Pineau A (1980) La fatigue des matériaux et des structures. Maloine

Oh C, Earmme Y, Song J (1997) Automated real-time measurements of fatigue crack length and crack opening load using unloading elastic compliance method. Int J Fatigue 19(2):169–176

Johnson H (1965) Calibrating the electric potential method for studying slow crack growth (calibration of electric potential technique to study slow or steady crack growth in high strength materials). Mater Res Stand 5:442–445

Mann T, Harkegaard G, Stark K (2007) Short fatigue crack growth in aluminium alloy 6082-T6. Int J Fatigue 29(9–11):1820–1826

Dawicke D, Sutton M, Newman Jr J, Bigelow C (1999) Measurement and analysis of critical CTOA for an aluminum alloy sheet. Fract Mech 25:358–379

Sutton M, Zhao W, McNeill S, Helm, J, Piascik R, Riddell W (1999) Local crack closure measurements: development of a measurement system using computer vision and a far-field microscope. Advances in fatigue crack closure measurement and analysis, pp 145–156

Tada H, Paris P, Irwin G (2000) The stress analysis of cracks handbook, 3rd edn

Lyons J, Liu J, Sutton M (1996) High-temperature deformation measurements using digital-image correlation. Exp Mech 36(1):64–70

Kovac J, Alaux C, Marrow T, Govekar E, Legat A (2010) Correlations of electrochemical noise, acoustic emission and complementary monitoring techniques during intergranular stress-corrosion cracking of austenitic stainless steel. Corros Sci 52(6):2015–2025

James M, Pacey M, Wei L, Patterson E (2003) Characterisation of plasticity-induced closure–crack flank contact force versus plastic enclave. Eng Fract Mech 70(17):2473–2487

Diaz F, Patterson E, Tomlinson R, Yates J (2004) Measuring stress intensity factors during fatigue crack growth using thermoelasticity. Fatigue Fract Eng Mater Struct 27(7):571–583

MCneill S, Peters W, Sutton M (1987) Estimation of stress intensity factor by digital image correlation. Eng Fract Mech 28(1):101–112

Réthoré J, Gravouil A, Morestin F, Combescure A (2005) Estimation of mixed-mode stress intensity factors using digital image correlation and an interaction integral. Int J Fract 132(1):65–79

Roux S, Hild F (2006) Stress intensity factor measurements from digital image correlation: post-processing and integrated approaches. Int J Fract 140(1):141–157

Roux S, Réthoré J, Hild F (2009) Digital image correlation and fracture. J Phys D: Appl Phys 42:214004–214024

Irwin G (1960) Plastic zone near a crack and fracture toughness. In: Proceedings of 7th Sagamore conference, pp 4–63

Tay T, Yap C, Tay C (1995) Crack tip and notch tip plastic zone size measurement by the laser speckle technique. Eng Fract Mech 52(5):879–885

Henninger C, Roux S, Hild F (2010) Enriched kinematic fields of cracked structures. Int J Solids Struct 47:3305–3316

ASTM Standard (1995) E647-95. In: 1995 ASTM annual book of standards, vol 3, pp 578

Xu T, Bea R (1997) Load shedding of fatigue fracture in ship structures. Mar Struct 10(1):49–80

AFNOR (1992) Produits siderurgiques, essais mecaniques, partie 2: fatigue mecanique de la rupture

Comite Europeen de Normalisation CE (1999) Protection contre la corrosion: terminologie essais de corrosion et protection cathodique, vol 1. AFNOR CEFRACOR

Williams M (1957) On the stress distribution at the base of a stationary crack. ASME J Appl Mech 24:109–114

Hamam R, Hild F, Roux S (2007) Stress intensity factor gauging by digital image correlation: application in cyclic fatigue. Strain 43(3):181–192

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Durif, E., Réthoré, J., Combescure, A. et al. Controlling Stress Intensity Factors During a Fatigue Crack Propagation Using Digital Image Correlation and a Load Shedding Procedure. Exp Mech 52, 1021–1031 (2012). https://doi.org/10.1007/s11340-011-9552-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-011-9552-6