Abstract

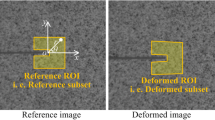

Existing methods of stress intensity factor (SIF) estimation are commonly based on the contact measurements of crack length with subsequent computation at taking into account the specimen geometry and loading process. The paper aims at the enhancement and verification of the non-contact and easily implemented technique for the assessment of mode I SIF during mechanical tests. Displacement fields constructed by digital image correlation (DIC) were approximated using Williams series in order to determine precise crack tip coordinates and proceed to the computation of stress intensity factor (SIF). The approximation algorithm was tested on linear-elastic and elastic–plastic ABAQUS models under various stress levels and the different Williams series term number. Besides numerical modeling of SIF, the algorithm was tested through assessment of crack propagation parameters under fatigue crack growth with the use of coarse- and fine-grained titanium samples. For the crack length range a/W ≤ 0.3, the approximation algorithm using the Williams series may be employed for estimating crack tip coordinates (crack length) and mode I stress intensity factor with satisfactory level of accuracy. The results of the study appeared to hold the promise of automated non-contact measurements of the crack length as well as stress intensity factor under fatigue crack propagation by employing DIC and appropriate high-performance real-time computing.

Similar content being viewed by others

Abbreviations

- \({a}_{n}\) , \({b}_{n}\) :

-

Constants in Williams series

- a/W :

-

Crack length divided on the specimen overall width

- Dx :

-

Error of the crack tip coordinate estimation along the x-axis

- G :

-

Shear modulus

- H :

-

Hessian matrix

- K I , K II :

-

Mode I and II stress intensity factors

- m :

-

Number of terms in Williams series

- N :

-

The number of displacement vectors, provided by digital image correlation computation

- R y :

-

Radius of the plastic zone

- Tx, Ty, R :

-

Terms in Williams series responsible for offset due to rigid body motion along x, y-axis, and rotation

- u :

-

Displacement components along x-axis

- v :

-

Displacement components along y-axis

- (\({x}_{0}\) , \({y}_{0}\)):

-

Crack tip coordinates along x- and y-axis

- \(\lambda\) :

-

The coefficient for the algorithm step in Newton–Raphson method

- ν :

-

Poisson's ratio

- σ y :

-

Yield stress

- AE:

-

Approximation error [pixels]

- CTE:

-

Crack tip coordinate estimation error [pixels]

- CTOD:

-

Crack tip opening displacement

- DIC:

-

Digital image correlation

- FEM:

-

Finite element modeling

- SIF:

-

Stress intensity factor

References

Irwin, G.R.: Analysis of stresses and strains near the end of a crack traversing a plate. J Appl Mech 24, 361–364 (1957)

Cherepanov, G.P.: Crack propagation in continuous media. J Appl Math Mech 31, 503–512 (1967). https://doi.org/10.1016/0021-8928(67)90034-2

Rice, J.R.: A path independent integral and the approximate analysis of strain concentration by notches and cracks. J Appl Mech 35, 379–386 (1968). https://doi.org/10.1115/1.3601206

Iyer, N.R., Alani, G.S., Ramachandra Murthy, A.: Advanced methodologies for fracture analysis and damage tolerant evaluation. Proc Indian Natl Sci Acad 82, 209–222 (2016). https://doi.org/10.16943/ptinsa/2016/48414

Giglio, M., Manes, A.: Terminal ballistic effect on the crack growth assessment of a helicopter rotor drive. Eng Fract Mech 78, 1542–1554 (2011). https://doi.org/10.1016/j.engfracmech.2011.01.024

Koohbor, B., Mallon, S., Kidane, A., Sutton, M.A.: A DIC-based study of in-plane mechanical response and fracture of orthotropic carbon fiber reinforced composite. Compos Part B Eng 66, 388–399 (2014). https://doi.org/10.1016/j.compositesb.2014.05.022

Otegui, J.L., Mohaupt, U.H., Burns, D.J.: A strain gauge technique for monitoring small fatigue cracks in welds. Eng Fract Mech 40, 549–569 (1991). https://doi.org/10.1016/0013-7944(91)90150-Y

Van Minnebruggen, K., Verstraete, M., Hertelé, S., De Waele, W.: Evaluation and comparison of double clip gauge method and delta 5 method for CTOD measurement in SE(T) specimens. J Test Eval 44, 20150127 (2016). https://doi.org/10.1520/jte20150127

(1983) Fatigue mechanisms: advances in quantitative measurement of physical damage. ASTM Spec. Tech. Publ.

Döll, W.: Optical interference measurements and fracture mechanics analysis of crack tip craze zones. In: Crazing in Polymers, pp. 105–168. Springer-Verlag, Berlin/Heidelberg (2005)

Theocaris, P.S., Gdoutos, E.E.: Photoelastic determination of KI stress intensity factors. Eng Fract Mech 7, 331–336 (1975). https://doi.org/10.1016/0013-7944(75)90014-4

Smith, D.G., Smith, C.W.: Photoelastic determination of mixed mode stress intensity factors. Eng Fract Mech 4, 357–366 (1972). https://doi.org/10.1016/0013-7944(72)90050-1

Marloff, R.H., Leven, M.M., Ringler, T.N., Johnson, R.L.: Photoelastic determination of stress-intensity factors - Paper describes several methods for calculating the stress-intensity factor from the photoelastically determined stress distributions near the tip of a notch. Exp Mech 11, 529–539 (1971). https://doi.org/10.1007/BF02329095

Sutton, M.A., Deng, X., Liu, J., Yang, L.: Determination of elastic-plastic stresses and strains from measured surface strain data. Exp Mech 36, 99–112 (1996). https://doi.org/10.1007/BF02328705

Pan, B.: Digital image correlation for surface deformation measurement: Historical developments, recent advances and future goals. Meas Sci Technol 29, 082001 (2018). https://doi.org/10.1088/1361-6501/aac55b

McNeill, S.R., Peters, W.H., Sutton, M.A.: Estimation of stress intensity factor by digital image correlation. Eng Fract Mech 28, 101–112 (1987). https://doi.org/10.1016/0013-7944(87)90124-X

Yates, J.R., Zanganeh, M., Tai, Y.H.: Quantifying crack tip displacement fields with DIC. Eng Fract Mech 77, 2063–2076 (2010). https://doi.org/10.1016/j.engfracmech.2010.03.025

Yoneyama, S., Morimoto, Y., Takashi, M.: Automatic evaluation of mixed-mode stress intensity factors utilizing digital image correlation. Strain 42, 21–29 (2006). https://doi.org/10.1111/j.1475-1305.2006.00246.x

Yoneyama, S., Ogawa, T., Kobayashi, Y.: Evaluating mixed-mode stress intensity factors from full-field displacement fields obtained by optical methods. Eng Fract Mech (2007). https://doi.org/10.1016/j.engfracmech.2006.08.004

Iryani, L., Dirgantara, T., Mihradi, S., Putra, I.S.: The effect of DIC parameters in the measurement of stress intensity factors KI and KII. J Mech Eng 10, 17–33 (2013)

Zhang, R., He, L.: Measurement of mixed-mode stress intensity factors using digital image correlation method. Opt Lasers Eng (2012). https://doi.org/10.1016/j.optlaseng.2012.01.009

Richter-Trummer, V., Moreira, P.M.G.P., Pastrama, S.D., et al.: Methodology for in situ stress intensity factor determination on cracked structures by digital image correlation. Int J Struct Integr (2010). https://doi.org/10.1108/17579861011099178

Gonzáles GLG, Diaz JG, González JAO et al (2017) Determining SIFs using DIC considering crack closure and blunting. In: Conference proceedings of the society for experimental mechanics series

Rybicki, E.F., Kanninen, M.F.: A finite element calculation of stress intensity factors by a modified crack closure integral. Eng Fract Mech 9, 931–938 (1977). https://doi.org/10.1016/0013-7944(77)90013-3

Beretta, S., Patriarca, L., Rabbolini, S.: Stress intensity factor calculation from displacement fields. Frat ed Integrita Strutt 11, 269–276 (2017). https://doi.org/10.3221/IGF-ESIS.41.36

Ktari, A., Baccar, M., Shah, M., et al.: A crack propagation criterion based on ΔcTOD measured with 2D-digital image correlation technique. Fatigue Fract Eng Mater Struct 37, 682–694 (2014). https://doi.org/10.1111/ffe.12153

Vavrik, D., Jandejsek, I.: Experimental evaluation of contour J integral and energy dissipated in the fracture process zone. Eng Fract Mech 129, 14–25 (2014). https://doi.org/10.1016/j.engfracmech.2014.04.002

Roux, S., Réthoré, J., Hild, F.: Digital image correlation and fracture: an advanced technique for estimating stress intensity factors of 2D and 3D cracks. J Phys D Appl Phys (2009). https://doi.org/10.1088/0022-3727/42/21/214004

Roux, S., Hild, F.: Stress intensity factor measurements from digital image correlation: post-processing and integrated approaches. Int J Fract 140, 141–157 (2006)

Réthoré, J., Roux, S., Hild, F.: Noise-robust stress intensity factor determination from kinematic field measurements. Eng Fract Mech 75, 3763–3781 (2008). https://doi.org/10.1016/j.engfracmech.2007.04.018

Hamam, R., Hild, F., Roux, S.: Stress intensity factor gauging by digital image correlation: Application in cyclic fatigue. Strain 43, 181–192 (2007)

Williams, M.L.: On stress distribution at base of stationary crack. J Appl Mech 24, 109–114 (1957). https://doi.org/10.1115/1.3640470

Williams, M.L.: The bending stress distribution at the base of a stationary crack. J Appl Mech 28, 78–82 (1960). https://doi.org/10.1115/1.3640470

Zanganeh, M., Lopez-Crespo, P., Tai, Y.H., Yates, J.R.: Locating the crack tip using displacement field data: a comparative study. Strain 49, 102–115 (2013). https://doi.org/10.1111/str.12017

Harilal, R., Vyasarayani, C.P., Ramji, M.: A linear least squares approach for evaluation of crack tip stress field parameters using DIC. Opt Lasers Eng 75, 95–102 (2015). https://doi.org/10.1016/j.optlaseng.2015.07.004

Gonzáles GLGG, Diaz JG, González JAOO, et al (2017) Determining SIFs using DIC considering crack closure and blunting. In: Conference proceedings of the society for experimental mechanics series. pp 25–36

Hellan, K.: Introduction to fracture mechanics. McGraw-Hill Inc, New York (1984)

Liu, M., Gan, Y., Hanaor, D.A.H., et al.: An improved semi-analytical solution for stress at round-tip notches. Eng Fract Mech 149, 134–143 (2015). https://doi.org/10.1016/j.engfracmech.2015.10.004

Tada, H., Paris, P.C., Irwin, G.R.: The stress analysis of cracks handbook, 3rd edn. ASME Press, New York (2000)

Yoneyama, S., Ogawa, T., Kobayashi, Y.: Evaluating mixed-mode stress intensity factors from full-field displacement fields obtained by optical methods. Eng Fract Mech 74, 1399–1412 (2007). https://doi.org/10.1016/j.engfracmech.2006.08.004

Acknowledgements

The research was funded by Government research assignment for ISPMS SB RAS, project FWRW-2021-0010.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Eremin, A., Lyubutin, P., Panin, S. et al. Application of digital image correlation and Williams series approximation to characterize mode I stress intensity factor. Acta Mech 233, 5089–5104 (2022). https://doi.org/10.1007/s00707-022-03374-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-022-03374-5