Abstract

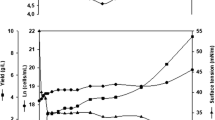

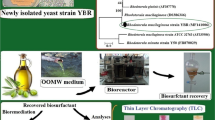

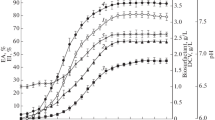

Biosurfactant production by Candida glabrata was studied using vegetable fat waste as substrate. A factorial design was initially carried out to investigate the effects and interactions of waste, yeast extract and glucose on the surface tension after 144 h cultivation. Maximum surface tension reduction was achieved with vegetable fat waste at 5% and yeast extract at 0.2%. The biosurfactant containing cell-free broth retained its surface-active properties after incubation at high temperatures, at a wide range of pH values and salt concentrations. Comparison between three solvent systems for surfactant recovery showed that ethyl acetate extracted both crude extracellular and intracellular biosurfactant with high product recovery. The isolated extracellular biosurfactant showed a CMC of 1% and the surface tension at that point was 24 mN m−1. Preliminary chemical composition revealed the presence of carbohydrates, proteins and lipids. The application of the crude biosurfactant to a soil–water-hydrophobic contaminant system was investigated and the apparent critical micelle concentration was determined at 7% of the broth, although the best oil removal (92.6%) had been obtained with 10% of the cell-free broth. The cost of application of the biosurfactant in soils was estimated based on the cost of a commercial biosurfactant.

Similar content being viewed by others

References

Banat IM (1995) Characterization of biosurfactants and their use in pollution removal—State of the Art. Acta Biotechnol 15:251–267

Bednarski W, Admczak M, Tomasik J, Plaszczyk M (2004) Application of oil refinery waste in the biosynthesis of glycolipids by yeast. Bioresour Technol 95:15–18

Casas JA, Garcia-Ochoa F (1999) Sophorolipid production by Candida bombicola: medium composition and culture methods. J Biosci Bioeng 88:488–494

CESIO (Comité europeén des agents de surface et leurs intermédiaires organics) (2001) Renewable Raw Materials Group. In: European Climate Change Programme (ECCP), Brussels

Coimbra CD, Rufino RD, Luna JM, Sarubbo LA (2009) Studies of the cell surface properties of Candida species and relation with the production of biosurfactants for environmental applications. Curr Microbiol 58:245–251

Cooper DG, Paddock DA (1984) Production of a biosurfactant from Torulopsis bombicola. Appl Environ Microbiol 47:173–176

Daniel HJ, Reuss M, Syldatk C (1998) Production of sophorolipids in high concentration from deproteinized whey and rapeseed oil in a two stage fed batch process using Candida bombicola ATCC 22214 and Cryptococcus curvatus ATCC 20509. Biotechnol Lett 20:1153–1156

Davila A-M, Marchal R, Vandecastele J-P (1992) Kinetics and balance of a fermentation free from product inhibition: sophorose lipid production by Candida bombicola. Appl Microbiol Biotechnol 38:6–11

Desai JD, Desai A (1992) Biosurfactants. In: Kosaric N (ed) Biosurfactants: production, properties and application. Surfactant science series, vol 48. Marcel Dekker, New York, pp 65–86

Dubois M, Gilles KA, Hamilton JK (1956) Colorimetric method for determination of sugar and related substances. Anal Chem 28:350–356

Durham DR, Kloos WE (1978) Comparative study of the total cellular fatty acids of Staphylococcus species of human origin. Int J Syst Bacteriol 28:223–228

Ehrenberg J (2002) Current situation and future prospects of EU industry using renewable raw materials. In: European Commission DG Enterprise Unit E.I.: Environmental Aspects of Industry Policy, Brussels

Garcia-Ochoa F, Casas JA (1999) Unstructured kinetic model for sophorolipid production by Candida bombicola. Enzym Microb Technol 25:613–621

Haba E, Espuny MJ, Busquets M, Manresa A (2000) Screening and production of rhamnolipids Pseudomonas aeruginosa 47T2 NCIB 40044 from waste frying oils. J Appl Microbiol 88:379–387

Ivshina IB, Kuyukina MS, Philp JC, Christofi N (1998) Oil desorption from mineral and organic materials using biosurfactant complexes produced by Rhodococcus species. World J Microbiol Biotechnol 14:711–717

Joshi S, Bharucha C, Jha S, Yadav S, Nerurkar A, Desai AJ (2008) Biosurfactant production using molasses and whey under thermophilic conditions. Bioresour Tecnol 99:195–199

Kappeli O, Muller M, Fiechter A (1978) Chemical and structural alterations at the cell surface of Candida tropicalis, induced by hydrocarbon substrate. J Bacteriol 133:952–958

Kitamoto D, Yanagishita H, Haraya K, Kitamoto HK (1998) Contribution of a chain-shortening pathway to the biosynthesis of the fatty acids of mannosylerythritol lipid (biosurfactant) in the yeast Candida antarctica: effect of β-oxidation inhibitors on biosurfactant synthesis. Biotechnol Lett 20:813–818

Manocha MS, San-Blas G, Centeno S (1980) Lipid composition of Paracoccidioides brasilienses: possible correlation with virulence of different strains. J Gen Microbiol 117:147–154

Mills WB, Lew CS, Loh JY (1998) Predictions of potential human health and ecological risks from power plant discharges of total residual chlorine and chloroform into rivers. Environ Sci Technol 32:2162–2171

Mukherjee S, Das P, Sen R (2006) Towards commercial production of microbial surfactants. Trends Biotechnol 24:509–515

Muthusamy K, Gopalakrishnan S, Ravi TK, Sivachidambaram P (2008) Biosurfactants: properties, commercial production and application. Curr Sci 94:737–746

Nitschke M, Pastore GM (2006) Production and properties of a surfactant obtained from Bacillus subtilis grown on cassava wastewater. Bioresour Technol 97:336–341

Ogawa S, Ota Y (2000) Influence of exogenous natural oils on the w-1 and w-2 hydroxy fatty acid moiety of sophorose lipid produced by Candida bombicola. Biosci Biotechnol Biochem 64:2466–2468

Oliveira FJS, Vasquez L, Campos NP, França FP (2009) Production of rhamnolipids by a Pseudomonas alcaligenes strain. Process Biochem 44:383–389. doi:10.1016/j.procbio.2008.11.014

Pandey A, Soccol CR, Mitchell D (2000) New developments in solid state fermentation: I- bioprocesses and products. Process Biochem 35:1153–1169

Pekin G, Vardar-Sukan F (2006) Production of sophorolipids using the yeast Candida bombicola ATTC22214 for applications in the food industry. J Eng Nat Sci 2:109–116

Rahman PKSM, Gakpe E (2008) Production, characterization and applications of biosurfactants—review. Biotechnology 7:360–370

Ramnani P, Kumar SS, Gupta R (2005) Concomitant production and downstream processing of alkaline protease and biosurfactant from Bacillus licheniformis RG1: bioformulation as detergent additive. Process Biochem 40:3352–3359

Rivera OMP, Moldes AB, Torrado AM, Domínguez JM (2007) Lactic acid and biosurfactants production from hydrolized distilled grape marc. Process Biochem 42:1010–1020

Rufino RD, Sarubbo LA, Campos-Takaki GM (2007) Enhancement of stability of biosurfactant produced by Candida lipolytica using industrial residue as substrate. World J Microbiol Biotechnol 23:729–734

Rufino RD, Sarubbo LA, Benicio BN, Campos-Takaki GM (2008) Experimental design for the production of tensio-active agent by Candida lipolytica. J Ind Microbiol Biotechnol 35:907–914

Sarubbo LA, Porto ALF, Campos-Takaki GM (1999) The use of babassu oil as substrate to produce bioemulsifiers by Candida lipolytica. Can J Microbiol 45:423–426

Sarubbo LA, Marçal MCR, Neves MLC, Silva MPC, Porto ALF, Campos-Takaki GM (2001) Bioemulsifier production in batch culture using glucose as carbon source by Candida lipolytica. Appl Biochem Biotechnol 95:59–67

Sarubbo LA, Luna JM, Campos-Takaki GM (2006) Production and stability studies of the bioemulsifier obtained from a new strain of Candida glabrata UCP 1002. Electron J Biotechnol 9:400–406

Sarubbo LA, Farias CBB, Campos-Takaki GM (2007) Co-utilization of canola oil and glucose on the production of a surfactant by Candida lipolytica. Curr Microbiol 54:68–73

Sen R (2008) Biotechnology in petroleum recovery: the microbial EOR. Prog Energy Combust Sci 34:714–724

Sobrinho HBS, Rufino RD, Luna JM, Salgueiro AA, Campos-Takaki GM, Leite LFC, Sarubbo LA (2008) Utilization of two agroindustrial by-products for the production of a surfactant by Candida sphaerica UCP0995. Process Biochem 43:912–917

StatSoft, Inc (2004) Statistica (data analysis software system), version 6. http://www.statsoft.com

Sun X, Puri RK (1997) Surfactant-enhanced solubility and mobility of polycyclic aromatic hydrocarbons in soil. In: Proceedings of the 12th annual conference on hazardous waste research. Kansas City, MO

Tuleva B, Christova N, Cohen R, Antonova D, Todorov T, Stoineva I (2009) Isolation and characterization of the trehalose tetraester biosurfactants from a soil strain Micrococcus luteus BN56. Process Biochem 44:135–141

Van Hamme JD, Singh A, Ward OW (2006) Physiological aspects. Part 1 in a series of papers devoted to surfactants in microbiology and biotechnology. Biotechnol Adv 24:604–620

Zinjarde S, Chinnathambi S, Lachke AH, Pant A (1997) Isolation of an emulsifier from Yarrowia lipolytica NCIM 3589 using a modified mini isoelectric focusing unit. Lett Appl Microbiol 24:117–121

Acknowledgments

This work was financed by National Council for Scientific and Technological Development (CNPq), Foundation for the Support of Science and Technology of the State of Pernambuco (FACEPE) and Catholic University of Pernambuco (UNICAP), Brazil.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

de Gusmão, C.A.B., Rufino, R.D. & Sarubbo, L.A. Laboratory production and characterization of a new biosurfactant from Candida glabrata UCP1002 cultivated in vegetable fat waste applied to the removal of hydrophobic contaminant. World J Microbiol Biotechnol 26, 1683–1692 (2010). https://doi.org/10.1007/s11274-010-0346-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11274-010-0346-2