Summary

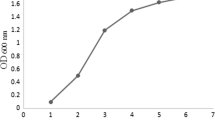

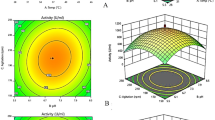

The structural gene yqhD from a wild-type Escherichia coli encoding 1,3-propanediol oxidoreductase isoenzyme and the structural gene dhaB from Citrobacter freundii encoding glycerol dehydratase were amplified by using the PCR method. The temperature control expression vector pHsh harboring the yqhD and dhaB genes was transformed into E. coli JM109 to yield the recombinant strain E. coli JM109 (pHsh-dhaB-yqhD). The response surface method (RSM) was then applied to further optimize the fermentation condition of the recombinant strain. A mathematical model was then developed to show the effect of each medium composition and their interactions on the production of 1,3-propanediol by recombinant strain E. coli JM109. The model estimated that a maximal yield of 1,3-propanediol (43.86 g/l) could be obtained when the concentrations of glycerol, yeast extract and vitamin B12 were set at 61.8 g/l, 6.2 g/l and 49 mg/l, respectively; and the fermentation time was 30 h. These predicted values were also verified by validation experiments. Compared with the values obtained by other runs in the experimental design, the optimized medium resulted in a significant increase in the yield of 1,3-propanediol. The yield and productivity under the optimal parameters and process can reach 43.1 g/l and 1.54 g/l/h. Maximum 1,3-propanediol yield of 41.1 g/l was achieved in a 5-l fermenter using the optimized medium. This makes the engineered strain have potential application in the conversion of glycerol to 1,3-propanediol on an industrial scale.

Similar content being viewed by others

References

Abbad-Andaloussi S., Du C., Raval G., Petitdemange H., 1996 Carbon and electron flow in Clostridium butyricum grown in chemostat culture on glycerol and on glucose Microbiology 142: 1149–1158

Ausubel F.M., Brent R., Kingston R.E., 1987 Current Protocols in Molecular Biology John Wiley & Sons New York, USA ISBN 0-417-63248-1

Barbirato F., Grivet J.P., Soucaille P., Bories A.A., 1996 3-Hydroxypropionaldehyde, an inhibitory metabolite of glycerol fermentation to 1,3-propanediol by Enterobacterial species Applied Microbiology and Biotechnology 62: 1448–1451

Biebl H., Menzel K., Zeng A.P., Deckwer W.D., 1999 Microbial production of 1,3-propanediol Applied Microbiology and Biotechnology 52: 289–297

Boenigk R., Bowien S., Gottschalk G., 1993 Fermentation of glycerol to 1,3-propanediol in continuous cultures of Citrobacter freundii Applied Microbiology and Biotechnology 38: 453–457

Box G.E., Benhnken D.W., 1960 Some new three level design for the study of quantitative variables Technometrics 2: 456–475

Du, X.L. 2004 Construction of temperature control vector pHsh. Masters thesis of Southern Yangtze University

Emptage, M., Haynie, S.L., Laffend, L.A., Pucci, J.P. & Whited, G. 2003 Process for biological of 1,3-propanediol with high titer. US 6514733 (US Patent)

Hounsa C.G., Aubry J.M., Dubourguier H.C., Hornez J.P. 1996 Application of factorial and Doehlert designs for optimization of pectate lyase production by a recombinant Escherichia coli Applied Microbiology and Biotechnology 45: 764–770

Huang H., Gong C.S., Tsao G.T. 2002 Production of 1,3-propanediol by Klebsiella pneumoniae Applied Biochemistry and Biotechnology 98: 687– 698

Laffend, L.A. & Nagarajan, V. 2000 Bioconversion of a fermentable carbon source to 1,3-propanediol by a single microorganism. US 6025184 (US Patent)

Liu J.Z., Weng L.P., Zhang Q.L., Xu H., Ji L.N. 2003 Optimization of glucose oxidase production by Aspergillus niger in a benchtop bioreactor using response surface methodology. World Journal of Microbiology and Biotechnology 19: 317–323

Menzel K., Zeng A.P., Deckwer W.D., 1997 High concentration and productivity of 1,3-propanediol from continuous fermentation of glycerol by Klebsiella pneumoniae Enzyme and Microbial Technology 20: 82–86

Nakamura C.E., Whited G.M., 2003 Metabolic engineering for the microbial production of 1,3-propanediol Current Opinion in Biotechnology 14: 454–459

Nemeth A., Kupcsulik B., Sevella B., 2003 1,3-Propanediol oxidoreductase production with Klebsiella pneumoniae DSM 2026 World Journal of Microbiology and Biotechnology 19: 659–663

Nikerel I.E., Toksoy E., Kirdar B., Yildirim R., 2005 Optimizing medium composition for TaqI endonuclease production by recombinant Escherichia coli cells using response surface methodology Process Biochemistry 40: 1633–1639

Sambrook J., Fritsch E.F., Maniatis T., 2001 Molecular Cloning: A Laboratory Manual Cold Spring Harbor Laboratory Press New York ISBN 7–03–010338–6

SAS Institute. (2003). SAS User’s Guide SAS Institute Inc. Cary, NC

Seifert C., Bowien S., Gottschalk G., Daniel R., 2001 Identification and expression of the genes and purification and characterization of the gene products involved in reactivation of coenzyme B12-dependent glycerol dehydratase of Citrobacter freundii European Journal of Biochemisty 268: 2369–2378

Skraly F.A., Lytle B.L., Cameron D.C., 1998 Construction and characterization of a1,3-propanediol operon Applied and Environmental Microbiology 1: 98–105

Sunitha K., Lee J.K., Oh T.K., 1999 Optimization of medium components for phytase production by E. coli using response surface methodology Bioprocess Engineering 21: 477–481

Xie L., Hall D., Eiteman M.A., Altman E., 2003 Optimization of recombinant aminolevulinate synthase prodution in Escherichia coli using factorial design Applied Microbiology and Biotechnology 63: 263–273

Xiu Z.L., 2001 Studies on medium design and pH control in the bioconversion of glycerol to 1,3-propanediol (in Chinese) Journal of Chemical Engineering of Chinese Universities 15: 397–402

Zeng A.P., Biebl H., 2002 Bulk-chemicals from biotechnology: The case of 1,3-propanediol production and the new trends Advances in Biochemical Engineering/Biotechnology 74: 239–258

Zhang X.M., Tang X.M., Zhuge J., 2005 Construction of novel recombinant Escherichia coli capable of producing 1,3-propanediol Chinese Journal of Biotechnology 21: 743–748

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, X., Li, Y., Zhuge, B. et al. Construction of a novel recombinant Escherichia coli strain capable of producing 1,3–propanediol and optimization of fermentation parameters by statistical design. World J Microbiol Biotechnol 22, 945–952 (2006). https://doi.org/10.1007/s11274-006-9139-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11274-006-9139-z