Abstract

With the introduction of modern low-weight high-strength materials, tools and dies in hot metal forming are exposed to increasingly demanding contact conditions. This requires use of surface engineering techniques and proper balance between core hardness and fracture toughness. However, it is not very straight forward which combination to use in terms of wear resistance. The aim of this work was to investigate the effect of Si content on properties of AISI H11-type hot work tool steel in relation to austenitizing and tempering temperature. Work was focused on the core fracture toughness and fracture toughness versus hardness ratio and how they affect galling and wear resistance of plasma nitrided hot work tool steel. In the case of high Si content, increased austenitizing temperature results in high core hardness but considerable drop in fracture toughness and wear resistance. However, for low Si content, increased core hardness is accompanied with improved fracture toughness and greatly improved wear resistance. Galling resistance on the other hand is more or less independent of the substrate properties and mainly depends on surface conditions and plasma nitriding process.

Similar content being viewed by others

References

Hansen, P. H.: Analysis of wear distribution in forging dies, PhD. Thesis. Technical University of Denmark, Lyngby (1990)

Sallit, I., Richard, C., Béranger, G., Kircher, D., Michaud, H.: Experimental study of wear behaviour of hot forging tool steels under dry conditions: 40CrMoV13 against C35E. Tribol. Lett. 12, 147–154 (2002)

Leskovšek, V., Šuštaršič, B., Jutriša, G.: The influence of austenitizing and tempering temperature on the hardness and fracture toughness of hot-worked H11 tool steel. J. Mater. Process. Technol. 178, 328–334 (2006)

Gåård, A.: Influence of tool microstructure on galling resistance. Tribol. Int. 57, 251–256 (2013)

Podgornik, B., Leskovšek, V.: Microstructure and origin of hot-work tool steel fracture toughness deviation. Metall. Mater. Trans. A 44, 5694–5702 (2013)

Bahrami, M., Mousavi, S.H., Golozar, M.A., Shamanian, M., Varahram, N.: Effects of conventional heat treatment on wear resistance of AISI H13 tool steel. Wear 258, 846–851 (2004)

Sevim, I., Eryurek, I.B.: Effect of fracture toughness on abrasive wear resistance of steels. Mater. Des. 27, 911–919 (2006)

Delagnes, D., Lamesle, P., Mathon, M.H., Mebarki, N., Levaillant, C.: Influence of silicon content on the precipitation of secondary carbides and fatigue properties of a 5% Cr tempered martensitic steel. Mater. Sci. Eng. A 394, 435–444 (2005)

Michaud, P., Delagnes, D., Lamesle, P., Mathon, M.H., Levaillant, C.: The effect of the addition of alloying elements on carbide precipitation and mechanical properties in 5% chromium martensitic steel. Acta Mater. 55, 4877–4889 (2007)

Mesquita, R.A., Kestenbach, H.-J.: On the effect of silicon on toughness in recent high quality hot work steels. Mater. Sci. Eng. A 528, 4856–4859 (2011)

Mesquita, R.A., Kestenbach, H.-J.: Influence of silicon on secondary hardening of 5 wt% Cr steels. Mater. Sci. Eng., A 556, 970–973 (2012)

Mesquita, R.A., Barbosa, C.A., Morales, E.V., Kestenbach, H.-J.: Effect of silicon on carbide precipitation after tempering of H11 hot work steels. Metall. Mater. Trans. A 42A, 461–472 (2011)

Altstetter, C.J., Cohen, M., Averbach, B.L.: Effect of silicon on the tempering of AISI 43XX steels. Trans. ASM. 55, 287–300 (1962)

Garrison Jr, W.M.: Influence of silicon on strength and toughness of 5 wt-% Cr secondary hardening steel. Mater. Sci. Technol. 3, 256–259 (1987)

Groche, P., Christiany, M.: Evaluation of the potential of tool materials for the cold forming of advanced high strength steels. Wear 302, 1279–1285 (2013)

Behrens, B.-A., Doege, E., Reinsch, S., Telkamp, K., Daehndel, H., Specker, A.: Precision forging processes for high-duty automotive components. J. Mater. Process. Technol. 185, 139–146 (2007)

Leskovšek, V., Podgornik, B.: Vacuum heat treatment, deep cryogenic treatment and simultaneous pulse plasma nitriding and tempering of P/M S390MC steel. Mater. Sci. Eng., A 531, 119–129 (2012)

Suchanek, J., Kuklik, V.: Influence of heat and thermochemical treatment on abrasion resistance of structural and tool steels. Wear 267, 2100–2108 (2009)

Paschke, H., Weber, M., Braeuer, G., Yilkiran, T., Behrens, B.-A., Brand, H.: Optimized plasma nitriding processes for efficient wear reduction of forging dies. Arch. Civ. Mech. Eng. 12, 407–412 (2012)

Podgornik, B., Hogmark, S.: Surface modification to improve friction and galling properties of forming tools. J. Mater. Process. Technol. 174, 334–341 (2006)

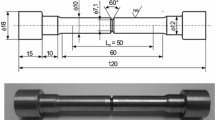

Podgornik, B., Zuzek, B., Leskovsek, V.: Experimental evaluation of tool steel fracture toughness using circumferentially notched and precracked tension bar specimen. Mater. Perform. Charact. 3, 87–103 (2014). doi:10.1520/mpc20130045

Ule, B., Leskovsek, V., Tuma, B.: Estimation of plain strain fracture toughness of AISI M2 steel from precracked round-bar specimens. Eng. Fract. Mech. 65, 559–572 (2000)

Podgornik, B., Hogmark, S., Pezdirnik, J.: Comparison between different test methods for evaluation of galling properties of surface engineered tool surfaces. Wear 257, 843–851 (2004)

Podgornik, B., Jerina, J.: Surface topography effect on galling resistance of coated and uncoated tool steel. Surf. Coat. Technol. 206, 2792–2800 (2012)

Sjöström, J., Bergström, J.: Evaluation of the cyclic behaviour during high temperature fatigue of hot work tool steels. In: Bergstrom, J., Fredriksson, G., Johansson, M., Kotik, O., Thuvander, F. (eds.) Proceedings 6th International Tooling Conference, pp. 721–736. Karlstad, Sweden (2002)

Nolan, D., Leskovsek, V., Jenko, M.: Estimation of fracture toughness of nitride compound layers on tool steel by application of the Vickers indentation method. Surf. Coat. Technol. 201, 182–188 (2006)

Acknowledgments

This work was supported by Unior d.d., Slovenia, who is greatly acknowledged for the support and supply of testing material.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Podgornik, B., Žužek, B., Kafexhiu, F. et al. Effect of Si Content on Wear Performance of Hot Work Tool Steel. Tribol Lett 63, 5 (2016). https://doi.org/10.1007/s11249-016-0695-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-016-0695-6