Abstract

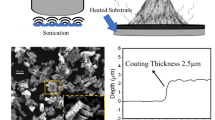

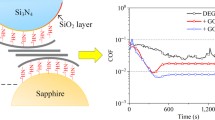

Graphene oxide nanosheet (GONS) coatings were fabricated by using electrodynamic spraying process (ESP) with the aim to utilize the coatings as a solid lubricant. Well-dispersed GONSs in a mixture of EtOH/H2O solution was deposited on Si (100) substrates. The characteristics of the coatings such as surface roughness and thickness were assessed with respect to the coating process parameters. Tribological properties of the GONS coatings with different thickness were investigated using a pin-on-reciprocating type of a tribotester under various applied loads. Surface morphology and chemical bonding composition of the coatings inside and outside of the wear track were characterized with atomic force microscope and Raman spectroscopy, respectively. The experimental results revealed that with proper ESP conditions, GONS coatings resulted in a low friction coefficient of ~0.1. This outcome was largely attributed to GONS transferred to the counter surface which remained stable throughout the sliding process. Furthermore, GONS coatings showed better surface protection ability and lower frictional property compared with single-layer graphene coatings. The results of this work demonstrate the feasibility of employing ESP to fabricate graphene-based solid lubricants cost effectively.

Similar content being viewed by others

References

Scharf, T., Prasad, S.: Solid lubricants: a review. J. Mater. Sci. 48, 511–531 (2013)

Wang, Z., Wang, C.B., Zhang, B., Zhang, J.Y.: Ultralow friction behaviors of hydrogenated fullerene-like carbon films: effect of normal load and surface tribochemistry. Tribol. Lett. 41, 607–615 (2011)

Chhowalla, M., Amaratunga, A.J.: Thin films of fullerene-like MoS2 nanoparticles with ultra-low friction and wear. Nature 41, 164–167 (2000)

Berman, D., Erdemir, A., Sumant, A.: Graphene: a new emerging lubricant. Mater. Today 17, 31–42 (2014)

Penkov, O., Kim, H.J., Kim, H.J., Kim, D.E.: Tribology of graphene: a review. Int. J. Precis. Eng. Manuf. 15, 577–585 (2014)

Kim, K.S., Lee, H.J., Lee, C.G., Lee, S.K., Jang, H.U., Ahn, J.H., Kim, J.H., Lee, H.J.: Chemical vapor deposition-grown graphene: the thinnest solid lubricant. ACS Nano 5, 5107–5114 (2011)

Won, M.S., Penkov, A., Kim, D.E.: Durability and degradation mechanism of graphene coatings deposited on Cu substrates under dry contact sliding. Carbon 54, 472–481 (2013)

Berman, D., Erdemir, A., Sumant, A.V.: Reduced wear and friction enabled by graphene layers on sliding steel surfaces in dry nitrogen. Carbon 59, 167–175 (2013)

Liang, H., Bu, Y., Zhang, J., Cao, Z., Liang, A.: Graphene oxide film as solid lubricant. ACS Appl. Mater. Interfaces 5, 6369–6375 (2013)

Wang, J., Liang, M., Fang, Y., Qiu, T., Zhang, J., Zhi, L.: Rod-coating: towards large-area fabrication of uniform reduced graphene oxide films for flexible touch screens. Adv. Mater. 24, 2874–2878 (2012)

Dua, V., Surwade, S.P., Ammu, S., Agnihotra, S.R., Jain, S., Roberts, K.E., Park, S., Ruoff, R.S., Manohar, S.K.: All-organic vapor sensor using inkjet-printed reduced graphene oxide. Angew. Chem. 49, 1–5 (2010)

Schlȕter, B., Mȕlhaupt, R., Kailer, A.: Synthesis and tribological characterization of stable dispersions of thermally reduced graphite oxide. Tribol. Lett. 53, 353–363 (2014)

Kim, D.E., Kim, C.L., Kim, H.J.: A novel approach to wear reduction of micro-components by synthesis of carbon nanotube-silver composite coating. CIRP Ann. Manuf. Technol. 60, 599–602 (2011)

Choy, K.L., Su, B.: Growth behavior and microstructure of CdS thin films deposited by an electrostatic spray assisted vapor deposition (ESAVD). Thin Soild Films 388, 9–14 (2001)

Park, S., Hwang, J., Kim, K., Jung, B., Kim, W., Hwang, J.: Spray deposition of electrohydrodynamically atomized polymer mixture for active layer fabrication in organic photovoltaics. Sol. Energy Mater. Sol. Cells 95, 352–356 (2011)

Kim, Y.G., Akbar, Z., Kim, D.Y., Jo, S.M., Jang, S.Y.: Aqueous dispersible graphene/Pt nanohybrids by green chemistry: application as cathodes for dye-sensitized solar cells. ACS Appl. Mater. Interfaces 5, 2053–2061 (2013)

Jaworek, A., Sobczyk, A.T.: Electrospraying route to nanotechnology: an overview. J. Electrost. 66, 197–219 (2008)

Ganan-Calvo, A.: Cone-jet analytical extension of Taylor’s electrostatic solution and the asymptotic universal scaling laws in electrospraying. Phys. Rev. Lett. 79, 217–220 (1997)

Rietveld, I.B., Kobayashi, K., Yamada, H., Matsushigea, K.: Morphology control of poly(vinylidene fluoride) thin film made with electrospray. J. Colloid Interfaces Sci. 198, 639–651 (2006)

Chen, C., Kelder, E., van der Put, P., Schoonman, J.: Morphology control of thin LiCoO2 films fabricated using the electrostatic spray deposition (ESD) technique. J. Mater. Chem. 6, 765–771 (1996)

Park, S., Park, J., Hwang, J.: Morphology characterization of phenyl-C61-butyric acid methyl ester films via an electrohydrodynamic spraying route. Thin Solid Films 550, 395–403 (2014)

Hummers, W., Offerman, R.: Preparation of graphitic oxide. J. Am. Chem. Soc. 80, 1339 (1958)

Zong, Z., Chen, C., Dokmeci, M., Wan, K.: Direct measurement of graphene adhesion on silicon surface by intercalation of nanoparticles. J. Appl. Phys. 107, 026104 (2010)

Deng, Z., Smolyanitsky, A., Li, Q., Feng, X., Cannara, R.: Adhesion-dependent negative friction coefficient on chemically modified graphite at the nanoscale. Nat. Mater. 11, 1032–1037 (2012)

Johnson, K.L.: Contact Mechanics. Cambridge University Press, United Kingdom (1985)

Shang, J., Ma, L., Li, J., Ai, W., Yu, T., Gurzadyan, G.G.: The origin of fluorescence from graphene oxide. Sci. Rep. (2012). doi:10.1038/srep00792

Sharma, P., Bhalla, V., Dravid, V., Shekhawat, G., Wu, J., Prasad, E., Suri, C.: Enhancing electrochemical detection on graphene oxide-CNT nanostructured electrodes using magneto-nanobioprobes. Sci. Rep. (2012). doi:10.1038/srep00877

Acknowledgments

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIP) (No. 2010-0018289).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, HJ., Penkov, O.V. & Kim, DE. Tribological Properties of Graphene Oxide Nanosheet Coating Fabricated by Using Electrodynamic Spraying Process. Tribol Lett 57, 27 (2015). https://doi.org/10.1007/s11249-015-0467-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-015-0467-8