Abstract

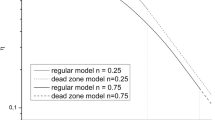

Heterogeneous catalysis is of paramount importance in many areas of gas conversion and processing in chemical engineering industries. In porous pellets, the catalytic reactions may be affected by diffusional limitations such that the global rate can be different from the intrinsic reaction rate. In the literature, a number of multicomponent diffusion flux closures have been applied to characterize the diffusion process within different units in chemical process plants. The main purpose of this paper is to outline the derivation of the different diffusion flux models: the rigorous Maxwell–Stefan and dusty gas models, and the simpler Wilke and Wilke–Bosanquet models. Usually the diffusion fluxes are derived and presented with respect to the molar average velocity definition. In this study, also the diffusion flux closures with respect to the mass average velocity definition is outlined. Thus, if the temperature equation and the momentum equation are used in the pellet model, a consistently closed set of pellet equations is obtained on mass basis holding only the mass average velocity. On the other hand, for the closed set of pellet equations on molar basis, the component balances hold the molar averaged velocity whereas the temperature and momentum equations hold the mass average velocity due to the physical laws applied deriving these fundamental balances. Nevertheless, the Maxwell–Stefan and dusty gas models are manipulated and put on the convenient Fickian form. The second purpose of this article is the evaluation of the diffusion flux closures derived. For this purpose, a transient model is developed to describe the evolution of the species composition, pressure, velocity, temperature, total concentration, and fluxes within a spherical pellet. The catalyst problem has been simulated for the methanol dehydration process producing dimethyl ether (DME), with computed efficiency factor values in the range 0.06–0.6 for pellet pore diameters of 0.1–100 nm. Identical results are expected for the mole and mass based pellet equations. However, deviations are obtained in the component fractions comparing the mass and mole based pellet model formulations where the mass fluxes were described according to the Wilke and Wilke–Bosanquet models. On the other hand, the rigorous Maxwell–Stefan and dusty gas models gave identical results.

Similar content being viewed by others

Abbreviations

- B :

-

Permeability, m2

- c :

-

Concentration, kmol/m3

- Cp :

-

Heat capacity, J/(kmol K)

- Cp′′:

-

Heat capacity, J/(kg K)

- D :

-

Diffusivity, m2/s

- \({\widetilde D_{ij}}\) :

-

Maxwell–Stefan diffusivities, m2/s

- D ij :

-

Binary diffusion coefficient for species i and j, m2/s

- D im :

-

Diffusion coefficient of species i in Wilke molar flux, m2/s

- \({D_{i{\rm m}}^{''}}\) :

-

Diffusion coefficient of species i in Wilke mass flux, m2/s

- D iK :

-

Knudsen diffusion coefficient for species i, m2/s

- D i,eff :

-

Bosanquet diffusivity, mole basis, m2/s

- \({D''_{i,{\rm eff}}}\) :

-

Bosanquet diffusivity, mass basis, m2/s

- d i :

-

Diffusional driving force, m−1

- d p :

-

Diameter of pellet, m

- d pore :

-

Average pore diameter, m

- g :

-

External force per unit mass, m/s2

- h :

-

Heat transfer coefficient, W/(m2K)

- ΔH :

-

Heat of reaction, J/kmol

- J :

-

Molecular diffusion flux, kmol/(s m2)

- j :

-

Mass diffusion flux, kg/(s m2)

- k :

-

Reaction rate constant, kmol/(kg h)

- k :

-

Boltzmann constant, 1.3805 · 10−23, J/K

- k :

-

Mass transfer coefficient, m/s

- K M, K W :

-

Adsorption constant, m3/kmol

- K :

-

Thermodynamic equilibrium constant, dimensionless

- M :

-

Molecular weight, kg/kmol

- N :

-

Number of collocation points, dimensionless

- n :

-

Number of species in gas mixture, dimensionless

- n i :

-

Combined mass flux of species i in gas mixture, kg/(m2s)

- N i :

-

Combined molar flux of species i in gas mixture, kmol/(m2s)

- p :

-

Pressure, Pa

- Q :

-

Heat conductivity flux, J/(m2s)

- R :

-

Gas constant, J/(kmol K)

- r :

-

Radial coordinate, m

- r :

-

Reaction rate, kmol/(kg s)

- r M :

-

Reaction rate, kmol/(kg h)

- r p :

-

Radius of pellet, m

- S :

-

Molecular source term, (kmol)/(m3s)

- S′′:

-

Mass source term, kg/(m3s)

- Ŝ :

-

Heat source term, J/(m3s)

- T :

-

Temperature, K

- t :

-

Time, s

- u :

-

Molar average velocity, m/s

- v :

-

Mass average velocity, m/s

- v i :

-

Velocity of species i with respect to fixed coordinates, m/s

- V :

-

Volume, m3

- x :

-

Mole fraction, dimensionless

- η :

-

Effectiveness factor, dimensionless

- \({\epsilon}\) :

-

Porosity, dimensionless

- \({\epsilon}\) :

-

Characteristic Lennar-Jones energy, J

- λ :

-

Conductivity, W/(m K)

- ρ :

-

Density, kg/m3

- τ :

-

Tortuosity, dimensionless

- μ :

-

Dynamic viscosity, kg/(m s)

- ω :

-

Mass fraction, dimensionless

- Ω :

-

Diffusion collision integral, dimensionless

- Σ :

-

Characteristic Lennard-Jones length, Å

- b:

-

Bulk

- i, j, n :

-

Species type

- M:

-

Methanol

- p:

-

Pellet

- r :

-

Radial direction

- ref:

-

Reference state

- W:

-

Water

- *:

-

Dimensionless variable

- ′:

-

Gas mixture with dust particles

- ′′:

-

Mass basis

- ′′:

-

Second-order derivative in finite difference scheme (69)

- b:

-

Bulk

- e:

-

Effective

- s:

-

Superficial

- s:

-

Pellet surface; equation (71)

- τ :

-

Time level

References

Berčič G., Levec J.: Intrinsic and global reaction rate of methanol dehydration over γ−Al2O3 pellets. Ind. Eng. Chem. Res. 31, 1035–1040 (1992)

Berčič G., Levec J.: Catalytic dehydration of methanol to dimethyl ether. Kinetic investigation and reactor simulation. Ind. Eng. Chem. Res. 32, 2478–2484 (1993)

Bhatia S.K., Nicholson D.: Some pitfalls in the use of the Knudsen equation in modelling diffusion in nanoporous materials. Chem. Eng. Sci. 66, 284–293 (2011)

Bird R.B., Stewart W.E., Lightfoot E.N.: Transport Phenomena. Wiley, New York (2002)

Bosanquet, C. H.: Wall effects in gas-temperature measurements. British TA Report BR-507 (1944)

Burghardt A., Aerts J.: Pressure changes during diffusion with chemical reaction in a porous pellet. Chem. Eng. Process. 23, 77–87 (1988)

Curtiss C.F., Hirschfelder J.O.: Transport properties of multicomponent gas mixtures. J. Chem. Phys. 17, 550–555 (1949)

Datta R., Vilekar S.A.: The continuum mechanical theory of multicomponent diffusion in fluid mixtures. Chem. Eng. Sci. 65, 5976–5989 (2010)

Diep B.T.: Thermodynamic equilibrium constants for the methanol–dimethyl ether–water system. J. Chem. Eng. Data 32, 330–333 (1987)

Dogˇu T.: Diffusion and reaction in catalyst pellets with bidisperse pore size distribution. Ind. Eng. Chem. Res. 37, 2158–2171 (1998)

Elnashaie S.S.E.H., Abashar M.E.E.: Steam reforming and methanation effectiveness factors using the dusty gas model under industrial conditions. Chem. Eng. Process. 32, 177–189 (1992)

Fick A.: On liquid diffusion. Philos. Mag. J. Sci. 10, 31–39 (1855)

Finlayson B.A.: The Method of Weighted Residuals and Variational Principles: Whit Applications in Fluid Mechanics, Heat and Mass Transfer, vol. 87 of Mathematics in Science and Engineering. Academic Press, New York (1972)

Geankoplis C.J.: Transport processes and separation process principles. Prentice Hall, Upper Saddle River (2003)

Graaf G.H., scholtens H., Stamhuis E.J., Beenackers A.A.C.M.: Intra-particle diffusion limitations in low-pressure methanol synthesis. Chem. Eng. Sci. 45, 773–783 (1990)

Horák Z., Schneider P.: Comparison of some models of porous media for gas diffusion. Chem. Eng. J. 2, 26–36 (1971)

Jackson R.: Transport in Porous Catalysts. Elsevier, Amsterdam (1977)

Jakobsen H.A.: Chemical Reactor Modeling. Multiphase Reactive Flows. Springer, Berlin (2008)

Jakobtorweihen S., Lowe C.P., Keil F.J., Smit B.: Diffusion of chain molecules and mixtures in carbon nanotubes: The effect of host lattice flexibility and theory of diffusion in the Knudsen regime. J. Chem. Phys. 127, 024904 (2007)

Kleijn, C.R.: Transport phenomena in chemical vapor deposition reactors. Ph.D. thesis, Technische Universiteit, Delft (1991)

Knudsen M.: The laws of the molecular current and the internal friction current of gases by channels. Ann. Phys. (Leipzig) 29, 75–130 (1909)

Knudsen M., Fisher W.J.: The molecular and the frictional flow of gases in tubes. Phys. Rev. 31, 586–588 (1910)

Krishna R.: Problems and pitfalls in the use of the Fick formulation for intraparticle diffusion. Chem. Eng. Sci. 48(5), 845–961 (1993)

Krishna R.: Describing the diffusion of guest molecules inside porous structures. J. Phys. Chem. C 113, 19756–19781 (2009)

Krishna R., van Baten J.M.: Influence of adsorption on the diffusion selectivity for mixture permeation across mesoporous membranes. J. Membr. Sci. 369, 545–549 (2011a)

Krishna R., van Baten J.M.: Investigating the validity of the Knudsen prescription for diffusivities in a mesoporous covalent organic framework. Ind. Eng. Chem. Res. 50, 7083–7087 (2011b)

Krishna R., van Baten J.M.: A molecular dynamics investigation of the unusual concentration dependencies of Fick diffusivities in silica mesopores. Microporous Mesoporous Mater. 138, 228–234 (2011c)

Krishna R., van Baten J.M.: Investigating the validity of the bosanquet formula for estimation of diffusivites in mesopores. Chem. Eng. Sci. 69, 684–688 (2012)

Krishna R., Wesselingh J.A.: The Maxwell–Stefan approach to mass transfer. Chem. Eng. Sci. 52(6), 861–911 (1996)

Kuijlaars K.J., Kleijn C.R., van den Akker H.E.A.: Multi-component diffusion phenomena in multiple-wafer chemical vapour deposition reactors. Chem. Eng. J. 57, 127–136 (1995)

Lommerts B.J., Graaf G.H., Beenackers A.: Mathematical modeling of internal mass transport limitations in methanol synthesis. Chem. Eng. Sci. 55, 5589–5598 (2000)

Lovik I., Hillestad M., Hertzberg T.: Long term dynamic optimization of a catalytic reactor system. Comput. Chem. Eng. 22, S707–S710 (1998)

Mason E.A., Malinauskas A.P.: Gas Transport in Porous Media: The Dusty Gas Model. Elsevier, Amsterdam (1983)

Maxwell J.C.: On the dynamical theory of gases. Phil. Trans. R. Soc. 157, 49–88 (1866)

Reid R.C., Prausnitz J.M., Poling B.E.: The properties of gases and liquids. McGraw-Hill, New York (1987)

Rezaie N., Jahanmiri A., Moghtaderi B., Rahimpour M.R.: A comparison of homogeneous and heterogeneous dynamic models for industrial methanol reactors in the presence of catalyst deactivation. Chem. Eng. Process. 44, 911–921 (2005)

Rice R.G., Do D.D.: Applied mathematics and modeling for chemical engineers. Wiley, New York (1995)

Rout K.R., Solsvik J., Nayak A.K., Jakobsen H.A.: A numerical study of multicomponent mass diffusion and convection in porous pellets for the sorption-enhanced steam methane reforming and desorption processes. Chem. Eng. Sci. 66, 4111–4126 (2011)

Sahimi M., Gavalas G.R., Tsotsis T.T.: Statistical and continuum models of fluid–solid reactions in porous media. Chem. Eng. Sci. 45, 1443–1502 (1990)

Salmi T., Wärnå J.: Modelling of catalytic packed-bed reactors—comparison of different diffusion models. Comput. Chem. Eng. 15, 715–727 (1991)

Serrin J.: Mathematical principles of classical fluid mechanics. In: Flugge, S., Truesdell, C. (eds) Handbuch der physik, vol. VIII, Springer, New York (1959)

Shahrokhi M., Baghmisheh G.R.: Modeling, simulation and control of a methanol synthesis fixed-bed reactor. Chem. Eng. Sci. 60, 4275–4286 (2005)

Smith J.M.: Chemical engineering kinetics, 3rd edn. McGraw-Hill, Singapore (1981)

Solsvik J., Jakobsen H.A.: A numerical study of a two property catalyst/sorbent pellet design for the sorption-enhanced steam–methane reforming process: modeling complexity and parameter sensitivity study. Chem. Eng. J. 178, 407–422 (2011)

Solsvik, J., Jakobsen, H.A.: Multicomponent mass diffusion in porous pellets: Effects of flux models on the pellet level and impacts on the reactor level. Application to methanol synthesis. Can. J. Chem. Eng. doi:10.1002/cjce.20680(2012)

Stefan, J.: Über das Gleichgewicht und die Bewegung insbesondere die Diffusion von Gasgemengen. Sitzber. Akad. Wiss. Wien 63, 63–124 (1871)

Taylor R., Krishna R.: Multicomponent Mass Transfer. Wiley, New York (1993)

Tomadakis M.M., Sotirchos S.V.: Ordinary, transition, and Knudsen regime diffusion in random capillary structures. Chem. Eng. Sci. 48(19), 3323–3333 (1993)

Vakili R., Pourazadi E., Eslamloueyan R., Rahimpour M.R.: Direct dimethyl ether (DME) synthesis through a thermally coupled heat exchanger reactor. Appl. Energy 88, 1211–1223 (2011)

Wilke C.R.: Diffusional properties of multicomponent gases. Chem. Eng. Prog. 46, 95–104 (1950)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Solsvik, J., Jakobsen, H.A. A Survey of Multicomponent Mass Diffusion Flux Closures for Porous Pellets: Mass and Molar Forms. Transp Porous Med 93, 99–126 (2012). https://doi.org/10.1007/s11242-012-9946-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11242-012-9946-7