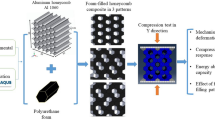

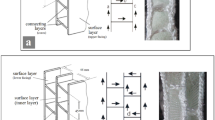

In the present study, the effect of the polyurethane foam-filled lattice core sandwich panel on the energy absorption and the compression strength was investigated. In the compression tests, it was found that the foam-filled sandwich panels have a greater load-carrying capacity compared to the sum of the unfilled specimens and the filled polyurethane block. Moreover, the energy absorption efficiency of foam-filled sandwich panels with higher relative density (5.1 and 5.7%) lattice cores was lower than that of the unfilled specimen when the compressive strain was small, whereas it was superior when the compressive strain reached about 0.1, and this superiority became more pronounced with the strain increase. Moreover, the energy absorption of foam-filled sandwich panels with lower relative density (4.43%) lattice cores was superior to that of the unfilled specimen.

Similar content being viewed by others

References

L. J. Gibson and M. F. Ashby, Cellular Solids: Structure and Properties, Cambridge University Press (1997).

Y. Hirose, H. Matsuda, G. Matsubara, et al., “Proposal of the concept of splice-type arrester for foam core sandwich panels,” Compos. Part A – Appl. S., 43, No. 8, 1318–1325 (2012).

Y. Rostamiyan, A. B. Fereidoon, A. Omrani, and D. D. Ganji, “Preparation, modeling, and optimization of mechanical properties of epoxy/HIPS/silica hybrid nanocomposite using combination of central composite design and genetic algorithm. Part 2. Studies on flexural, compression, and impact strength,” Strength Mater., 45, No. 6, 703–715 (2013).

Y. Rostamiyan and A. B. Fereidoon, “Preparation, modeling, and optimization of mechanical properties of epoxy/HIPS/silica hybrid nanocomposite using combination of central composite design and genetic algorithm. Part 1. Study of damping and tensile strengths,” Strength Mater., 45, No. 5, 619–634 (2013).

C. C. Foo, G. B. Chai, and L. K. Seah, “A model to predict low-velocity impact response and damage in sandwich composites,” Compos. Sci. Technol., 68, No. 6, 1348–1356 (2008).

A. Ajdari, H. Nayeb-Hashemi, and A. Vaziri, “Dynamic crushing and energy absorption of regular, irregular and functionally graded cellular structures,” Int. J. Solids Struct., 48, Nos. 3–4, 506–516 (2011).

H. Bart-Smith, J. W. Hutchinson, and A. G. Evans, “Measurement and analysis of the structural performance of cellular metal sandwich construction,” Int. J. Mech. Sci., 43, No. 8, 1945–1963 (2001).

H. Fan, Q. Zhou, W. Yang, and Z. Jingjing, “An experiment study on the failure mechanisms of woven textile sandwich panels under quasi-static loading,” Compos. Part B – Eng., 41, No. 8, 686–692 (2010).

A. Levy, J. Kratz, and P. Hubert, “Air evacuation during vacuum bag only prepreg processing of honeycomb sandwich structures: In-plane air extraction prior to cure,” Compos. Part A – Appl. S., 68, 365–376 (2015).

S. Shi, Z. Sun, X. Hu, and H. Chen, “Carbon-fiber and aluminum-honeycomb sandwich composites with and without Kevlar-fiber interfacial toughening,” Compos. Part A – Appl. S., 67, 102–110 (2014).

S. Rao, R. Das, and D. Bhattacharyya, “Investigation of bond strength and energy absorption capabilities in recyclable sandwich panels,” Compos. Part A – Appl. S., 45, 6–13 (2013).

J. Kratz and P. Hubert, “Anisotropic air permeability in out-of-autoclave prepregs: Effect on honeycomb panel evacuation prior to cure,” Compos. Part A – Appl. S., 49, 179–191 (2013).

B. Wang, L. Wu, L. Ma, et al., “Mechanical behavior of the sandwich structures with carbon fiber-reinforced pyramidal lattice truss core,” Mater. Design, 31, No. 5, 2659–2663 (2010).

L. Liu, H. Wang, and Z. Guan, “Experimental and numerical study on the mechanical response of Nomex honeycomb core under transverse loading,” Compos. Struct., 121, 304–314 (2015).

R. Roy, S.-J. Park, J.-H. Kweon, and J.-H. Choi, “Characterization of Nomex honeycomb core constituent material mechanical properties,” Compos. Struct., 117, 255–266 (2014).

A. Karakoç and J. Freund, “Experimental studies on mechanical properties of cellular structures using Nomex® honeycomb cores,” Compos. Struct., 94, No. 6, 2017–2024 (2012).

C. J. Yungwirth, D. D. Radford, M. Aronson, and H. N. G. Wadley, “Experiment assessment of the ballistic response of composite pyramidal lattice truss structures,” Compos. Part B – Eng., 39, No. 3, 556–569 (2008).

J. Xiong, L. Ma, L. Wu, et al., “Fabrication and crushing behavior of low density carbon fiber composite pyramidal truss structures,” Compos. Struct., 92, No. 11, 2695–2702 (2010).

J.-H. Lim and K.-J. Kang, “Mechanical behavior of sandwich panels with tetrahedral and Kagome truss cores fabricated from wires,” Int. J. Solids Struct., 43, No. 17, 5228–5246 (2006).

V. Deshpande and N. Fleck, “Collapse of truss core sandwich beams in 3-point bending,” Int. J. Solids Struct., 38, Nos. 36–37, 6275–6305 (2001).

V. S. Deshpande and N. A. Fleck, “Energy absorption of an egg-box material,” J. Mech. Phys. Solids, 51, No. 1, 187–208 (2003).

A. G. Hanssen, M. Langseth, and O. S. Hopperstad, “Optimum design for energy absorption of square aluminium columns with aluminium foam filler,” Int. J. Mech. Sci., 43, No. 1, 153–176 (2001).

A. M. Harte, N. A. Fleck, and M. F. Ashby, “Sandwich panel design using aluminum alloy foam,” Adv. Eng. Mater., 2, No. 4, 219–222 (2000).

J. W. Hutchinson and M. Y. He, “Buckling of cylindrical sandwich shells with metal foam cores,” Int. J. Solids Struct., 37, Nos. 46–47, 6777–6794 (2000).

J. H. Kim, Y. S. Lee, B. J. Park, and D. H. Kim, “Evaluation of durability and strength of stitched foam-cored sandwich structures,” Compos. Struct., 47, Nos. 1–4, 543–550 (1999).

R. J. D’Mello and A. M. Waas, “Synergistic energy absorption in the axial crush response of filled circular cell honeycombs,” Compos. Struct., 94, No. 5, 1669–1676 (2012).

F. Tarlochan, S. Ramesh, and S. Harpreet, “Advanced composite sandwich structure design for energy absorption applications: Blast protection and crashworthiness,” Compos. Part B – Eng., 43, No. 5, 2198–2208 (2012).

S. H. Yoo and S. H. Chang, “An experimental study on energy absorbing structures made of fabric composites,” Compos. Struct., 86, No. 1, 211–219 (2008).

ASTM C365-00. Standard Test Method for Flatwise Compressive Properties of Sandwich Cores, ASTM International, West Conshohocken, PA (2000).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 6, pp. 84 – 94, November – December, 2016.

Rights and permissions

About this article

Cite this article

Rostamiyan, Y., Norouzi, H. Flatwise Compression Strength and Energy Absorption of Polyurethane Foam-Filled Lattice Core Sandwich Panels. Strength Mater 48, 801–810 (2016). https://doi.org/10.1007/s11223-017-9827-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-017-9827-y