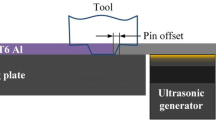

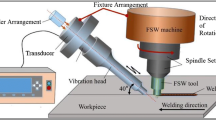

A new welding method: ultrasonic assisted friction stir spot welding (UAFSSW) was put forward in the present study. UAFSSW was successfully applied to weld dissimilar AZ31 Mg alloy and 6061 Al alloy. Results show that for either conventional FSSW or UAFSSW, sound joints are obtained with the upper Mg alloy and lower Al alloy configurations. Ultrasonic vibration is beneficial for the upward flow of lower aluminum alloy, the increase of the stir zone (SZ) width and the refinement of the grains in the SZ. All cross sections of the Al–Mg joints exhibit the formation of intermetallic compounds (IMC) in the SZ. The crack of the conventional FSSW joint propagates exactly along the interface between the dissimilar materials and exhibits an inverted V-shaped morphology. After reaching the highest point of the hook defect, crack of the UAFSSW joint extends to the keyhole, leaving a portion of Mg alloy on the lower sheet. Conventional FSSW and UAFSSW joints show different IMC compositions at the faying interface.

Similar content being viewed by others

References

Y. H. Yin, A. Ikuta, and T. H. North, “Microstructural features and mechanical properties of AM60 and AZ31 friction stir spot welds,” Mater. Des., 31, 4764–4776 (2010).

H. Badarinarayan, Y. Shi, X. Li, and K. Okamoto, “Effect of tool geometry on hook formation and static strength of friction stir spot welded aluminum 5754-O sheets,” Int. J. Mach. Tool. Manuf., 49, 814–823 (2009).

R. Z. Xu, D. R. Ni, Q. Yang, et al., “Influencing mechanism of Zn interlayer addition on hook defects of friction stir spot welded Mg–Al–Zn alloy joints,” Mater. Des., 69, 163–169 (2015).

Z. H. Zhang, X. Q. Yang, J. L. Zhang, et al., “Effect of welding parameters on microstructure and mechanical properties of friction stir spot welded 5052 aluminum alloy,” Mater. Des., 32, 4461–4470 (2011).

W. Y. Li, J. F. Li, Z. H. Zhang, et al., “Improving mechanical properties of pinless friction stir spot welded joints by eliminating hook defect,” Mater. Des., 62, 247–254 (2014).

S. Babu, G. D. Janaki Ram, P. V. Venkitakrishnan, et al., “Microstructure and mechanical properties of friction stir lap welded aluminum alloy AA2014,” J. Mater. Sci. Technol., 28, No. 5, 414–426 (2012).

Y. C. Chen and K. Nakata, “Friction stir lap joining aluminum and magnesium alloys,” Scripta Mater., 58, 433–436 (2008).

R. Cao, Q. Huang, J. H. Chen, and P. C. Wang, “Cold metal transfer spot plug welding of AA6061-T6 to galvanized steel for automotive applications,” J. Alloys Compd., 585, 622–632 (2014).

Y. H. Yin, N. Sun, T. H. North, and S. S. Hu, “Influence of tool design on mechanical properties of AZ31 friction stir spot welds,” Sci. Technol. Weld. Join., 15, No. 1, 81–86 (2010).

S. Bozzi, A. L. Helbert-Etter, T. Baudin, et al., “Influence of FSSW parameters on fracture mechanisms of 5182 aluminum welds,” J. Mater. Process. Technol., 210, 1429–1435 (2010).

S. O. Yoon, M. S. Kang, Y. J. Kwon, et al., “Influences of tool plunge speed and tool plunge depth on friction spot joining of AA5454-O aluminum alloy plates with different thicknesses,” Trans. Nonferrous Met. Soc. China, 22, s629–s633 (2012).

V. X. Tran, J. Pan, and T. Pan, “Fatigue behavior of aluminum 5754-O and 6111-T4 spot friction welds in lap-shear specimens,” Int. J. Fatigue, 30, 2175–2190 (2008).

H. M. Rao, W. Yuan, and H. Badarinarayan, “Effect of process parameters on mechanical properties of friction stir spot welded magnesium to aluminum alloys,” Mater. Des., 66, 235–245 (2015).

P. C. Lin, Z. M. Su, R. Y. He, and Z. L. Lin, “Failure modes and fatigue life estimations of spot friction welds in cross-tension specimens of aluminum 6061-T6 sheets,” Int. J. Fatigue, 38, 25–35 (2012).

Y. S. Sato, A. Shiota, H. Kokawa, et al., “Effect of interfacial microstructure on lap shear strength of friction stir spot weld of aluminum alloy to magnesium alloy,” Sci. Technol. Weld. Join., 15, No. 4, 319–324 (2010).

Y. Rostamiyan, A. Seidanloo, H. Sohrabpoor, and R. Teimouri, “Experimental studies on ultrasonically assisted friction stir spot welding of AA6061,” Arch. Civ. Mech. Eng., 15, 335–346 (2015).

X. C. Liu and C. S. Wu, “Material flow in ultrasonic vibration enhanced friction stir welding,” J. Mater. Process. Technol., 225, 32–44 (2015).

L. Shi, C. S. Wu, and X. C. Liu, “Modeling the effects of ultrasonic vibration on friction stir welding,” J. Mater. Process. Technol., 222, 91–102 (2015).

Acknowledgments

This work is supported by the National Natural Science Foundation of China (No. 51204111), the Education Department Foundation of Liaoning Province (Nos. LJQ2012015 and L2012047), the Natural Science Foundation of Liaoning Province (No. 2013024004) and the Project of Science and Technology Department of Liaoning Province (No. 2013222007).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 1, pp. 7 – 12, January – February, 2016.

Rights and permissions

About this article

Cite this article

Ji, S.D., Li, Z.W., Ma, L. et al. Investigation of Ultrasonic Assisted Friction Stir Spot Welding of Magnesium Alloy to Aluminum Alloy. Strength Mater 48, 2–7 (2016). https://doi.org/10.1007/s11223-016-9730-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-016-9730-y