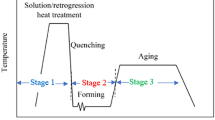

The effect of aging treatment on the surface roughness and mechanical properties of AA6061 and AA7075 alloys was studied. Microhardness and tensile tests were used to investigae the mechanical properties. X-ray diffraction analysis was used to investigate the surface of the specimens. Furthermore, after tensile tests fractured surfaces were examined with scanning electron microscopy. An atomic force microscope was employed for analysis of the effect of aging treatment on surface roughness. Higher surface roughness with an increase in the volume fraction of the precipitate was revealed.

Similar content being viewed by others

References

N. Yazdian, F. Karimzadeh, and M.Tavoosi, “Microstructural evolution of nanostructure 7075 aluminum alloy during isothermal annealing,” J. Alloys Compounds, 493, 137–141 (2010).

F. Hayat, “The effects of the welding current on heat input, nugget geometry, and the mechanical and fractural properties of resistance spot welding on Mg/Al dissimilar materials,” Mater. Design, 32, 2476–2484 (2011).

Y. B. Yan, Z. W. Zhang, W. Shen, et al., “Microstructure and properties of magnesium AZ31B–aluminum7075 explosively welded composite plate,” Mater. Sci. Eng. A, 527, 2241–2245 (2010).

W. S. Miller, L. Zhuang, J. Bottema, et al., “Recent development in aluminium alloys for the automotive industry,” Mater. Sci. Eng. A, 280, 37–49 (2000).

J. F. Li, Z. W. Peng, C. X. Li, et al., “Mechanical properties, corrosion behaviors and microstructures of 7075 aluminium alloy with various aging treatments,” Trans. Nonferrous Metals Soc. China, 18, No. 4, 755–762 (2008).

T. Wang, Z. M. Yin, and K. Shen, “Single-aging characteristics of 7055 aluminum alloy,” Trans. Nonferrous Metals Soc. China, 17, No. 3, 548–552 (2007).

H. Kaya, “Dependence of electrical resistivity on temperature and composition of Al–Cu alloys,” Mater. Res. Innov., 16, No. 3, 224–229 (2012).

T. Szymczak, Z. Kowalewski, and L. Dietrich, “Experimental analysis of creep and fatigue of light multifunctional aluminium alloys,” Mater. Res. Innov., 15, No. 1, 53–56 (2011).

Z. Yang, J. P. Li, J. X. Zhang, et al., “Review on research and development of magnesium alloys,” Acta Metall. Sinica, 21, 313–328 (2008).196

G. Das, M. Das, S. Ghosh, et al., “Effect of aging on mechanical properties of 6063 Al-alloy using instrumented ball indentation technique,” Mater. Sci. Eng. A, 527, 1590–1594 (2010).

H. Demir and S. Gündüz, “The effects of aging on machinability of 6061 aluminium alloy,” Mater. Design, 30, 1480–1483 (2009).

D. G. Altenpohl, Aluminum: Technology, Applications and Environment: A Profile of a Modern Metal, 6th edition, Wiley (1998).

L. P. Troeger and E. A. Starke, “Microstructural and mechanical characterization of a superplastic 6xxx aluminum alloy,” Mater. Sci. Eng. A, 277, 102–114 (2000).

S. J. Murtha, “New 6XXX aluminum alloy for automotive body sheet applications,” SAE Int. J. Mater. Manufact., 104, 657–666 (1995).

S. D. Liu, Y. Zhang, W. J. Liu, et al., “Effect of step-quenching on microstructure of aluminum alloy 7055,” Trans. Nonferrous Metals Soc. China, 20, No. 1, 1–6 (2010).

T. Wang, Z. M. Yin, and K. Shen, “Single-aging characteristics of 7055 aluminum alloy,” Trans. Nonferrous Metals Soc. China, 17, No. 3, 548–552 (2007).

J.-F. Li, Z. W. Peng, C. X. Li, et al., “Mechanical properties, corrosion behaviors and microstructures of 7075 aluminum alloy with various aging treatments,” Trans. Nonferrous Metals Soc. China, 18, No. 4,755–762 (2008).

F. Ozturk, A. Sisman, S. Toros, et al., “Influence of aging treatment on mechanical properties of 6061 aluminum alloy,” Mater. Design, 31, 972–975 (2010).

H. Khalid Rafi, G. D. Janaki Ram, G. Phanikumar, and K. Prasad Rao, “Microstructure and tensile properties of friction welded aluminum alloy AA7075-T6,” Mater. Design, 31, 2375–2380 (2010).

A. Meyveci, I. Karacan, U. Caligülü, and H. Durmus, “Pin-on-disc characterization of 2xxx and 6xxx aluminium alloys aged by precipitation age hardening,” J. Alloys Compounds, 491, 278–283 (2010).

H. Maamar, R. Rabah Otmani, T. Fahssi, et al., “Heat treatment and welding effects on mechanical properties and microstructure evolution of 2024 and 7075 aluminium alloys,” Metal (Hradec nad Moravici), 13–15.5.2008, 1–7 (2008).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Traslated from Problemy Prochnosti, No. 2, pp. 45 – 53, March – April, 2014.

Rights and permissions

About this article

Cite this article

Sevim, I., Sahin, S., Cug, H. et al. Effect of Aging Treatment on Surface Roughness, Mechanical Properties, and Fracture Behavior of 6XXX and 7XXX Aluminum Alloys. Strength Mater 46, 190–197 (2014). https://doi.org/10.1007/s11223-014-9535-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-014-9535-9