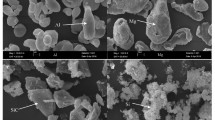

An electron microscope and local x-ray microanalysis are used to determine quantitative and qualitative compositions of mullitized glass, i.e., the main structural element of ceramic providing finished object strength during research into compositions of pyrophyllite and aluminum containing nanotechnogenic raw material ceramic mix compositions.

Similar content being viewed by others

References

V. Z. Abdrakhimov, “Use of aluminum-containing waste in production of ceramic materials for various Purposes,” Refract. Indust. Ceram., 54(1), 7 – 16 (2013).

V. Z. Abdrakhimov and E. S. Abdrakimova, “Study of phase composition of ceramic materials based on nonferrous metallurgy, chemical, and petrochemical industry aluminum-containing waste,” Refract. Indust. Ceram., 56(1), 5 – 10 (2015).

A. K. Kairakbaev, V. Z. Abdrakhimov, and E. S. Abdrakhimova, “Study of the effect of Al2O3 on acid and thermal shock resistance of acid-resistant refractories using a regression analysis method,” Refract. Indust. Ceram., 56(3), 276 – 280 (2015).

E. S. Abdrakhimova, “Study of acid-resistant material properties based on nonferrous metallurgy waste using regression analysis,” Refract. Indust. Ceram., 56(5), 510 – 516 (2015).

E. S. Abdrakhimova and V. Z. Abdrakhimov, “Effect of firing temperature and gas atmosphere on acid-resistant material pore structure formation,” Refract. Indust. Ceram., 57(1), 59 – 64 (2 – 16).

E. S. Abdrakhimova, V. Z. Abdrakhimov, D. V. Abdrakhimov, and A. V. Abdrakhimov, “Argillaceous part of zircon-ilmenite ore gravitation tailings – raw material for producing ceramic materials,” Ogneupor. Tekhn. Keram., No. 5, 38 – 42 (2005).

E. S. Abdrakhimova and V. Z. Abdrakhimov, “Physicochemical methods for studying the mineral composition and structure of the argillaceous part of zircon-ilmenite ore gravitation tailings,” Refract. Indust. Ceram., 52(1), 1 – 5 (2011).

E. S. Abdrakhimova and V. Z. Abdrakhimov, “Study of acid-resistant clay materials od different chemical composition,” Novye Ogneupory, No. 7, 12 – 18 (2012).

E. S. Abdrakhimova and V. Z. Abdrakhimov, “Processes occurring during firing of the clay part of zircon-ilmenite gravitation tailings,” Novye Ogneupory, No. 3, 13 – 19 (2009).

E. S. Abdrakhimova, “Formation of the structure of acid-resistant refractories occurring during firing of the clay part of zircon-ilmenite gravitation tailings,” Novye Ogneupory, No. 9, 12 – 15 (2009).

A. G. Bekhetin, Course in Mineralogy [in Russian], Gosgeoltekhizdat, Moscow (1961).

E. S. Abdrakhimova and V. Z. Abdrakhimov, Base of Engineering Ceramics [in Russian[, Vost. Kazakh. Gos. Techn. Univ., Ust’Kamenogorsk (2001).

E. S. Abdrakhimova, “Physicochemical study of Nikol’sk deposit pyrophillite,” Novye Ogneupory, No. 2, 10 – 12 (2010).

E. S. Abdrakhimova, I. M. De, and V. Z. Abdrakhimov, “Facing plates made from production waste and pyrophillite,” Kompleks. Ispol. Mineral. Syr., No. 5, 86 – 89 (1998).

V. Z. Abdrakhimov, “Pyrophillite as a raw material for the ceramic industry,” VNIIÉSM Keram. Prom., Moscow,No. 3, 7 – 8 (1989).

E. S. Abdrakhimova, “Effect of pyrophilllite on physicomechanical properties and acid-resistance of refractories,” Novye Ogneupory, No. 4, 15 – 19 (2009).

E. S. Abdrakhimova, “Effect of pyrophilllite on the drying properties of acid-resistant refractories based on the clay part of zirconilmenite gravitation tailings,” Novye Ogneupory, No. 11, 17 – 19 (2009).

V. Z. Abdrakhimova and E. S. Abdrakhimov, Course of Lectures on Ceramic Material Technology [in Russian], Samara Akad. Gorod. Munits. Uprav., Samara (2011).

E. S. Abdrakhimova, V. Z. Abdrakhimov, I. Yu. Roshchupkina, and Yu. B. Myshentseva, “Experimental study of physicochemical processes during firing acid-resistant refractories based on traditional natural materials and production waste,” Novye Ogneupory, No. 1, 45 – 51 (2012).

V. Z. Abdrakhimov, A. I. Khlystov, and V. K. Semenychev, “Use of technogenic formations in manufacture of refractory composites without firing,” Novye Ogneupory, No. 5, 53 – 59 (2010).

A. K. Kairakbaev, E. S. Abdrakhimova, and V. Z. Abdrakhimov, “Effect of high-alumina nanotechnogenic waste of petrochemistry on sinter brick heat resistance,” Steklo Keram., No. 9, 32 – 38 (2015).

V. Z. Abdrakhimov, “Ecological and practical aspects of using high-alumina petrochemistry waste in manufacture of acid-resistant refractories,” Novye Ogneupory, No. 1, 40 – 43 (2010).

V. Z. Abdrakhimov, G. R. Khasaev, and E. S. Abdrakhimova, “Ecological, theoretical, and practical aspects of using aluminium-containing waste in the production of ceramic materials for different purposes without using traditional natural raw material,” Ékol. Prom. Rossii, No. 5, 28 – 32 (2013).

I. V. Kovkov, V. Z. Abdrakhimov, and A. V. Kolpakov, “Study of the phase composition of materials based on aluminum-containing waste,” Izv. Vyssh. Ucgebn. Zaved., Stroit., No. 10, 20 – 29 (2012).

V. Z. Abdrakhimov and V. K. Semenychev, “Effect of petrochemical high-alumina waste on the structure of porous acid-resistant refractory,” Novye Ogneupory, No. 9, 148 – 151 (2010).

E. S. Abdrakhimova, E. V. Vdvina, A. V. Abdrakhimov, and V. Z. Abdrakhimov, “Study of glassy phase mullitization during firing of ceramic composite materials based on beidellite clay and mineral wool production waste,” Izv. Vyssh. Uchebn. Zaved., Stroit., No. 1, 56 – 62 (2008).

E. S. Abdrakhimova and V. Z. Abdrakhimov, Physicochemical Processes During Acid-Resistant Refractory Firing [in Russian, Nedra, St. Petersburg (2003).

D. Zh. Gol’denshtein, “Electron-probe microanalysis in metallurgy,” Proc. Conf. Moscow. Technol. Inst (1974).

E. S. Abdrakhimova and V. Z. Abdrakhimov, “Mullitization of glass phase during firing clay materials of differ3ent chemical and mineral composition,” Bashkir. Khim. Zh., 13, No. 4, 130 – 132 (2005).

V. F. Pavlov, “Features of silica transformation contained in clay,” Trudy Inst. NIIstroikeramika, No. 38, 3 – 11 (1973).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 11, pp. 16 – 20, November, 2016.

Rights and permissions

About this article

Cite this article

Abdrakhimova, E.S. Effect of Aluminum-Containing Nanotechnogenic Raw Material and Pyrophillite on Glass Phase Mullitization in Composite Acid-Resistant Ceramic. Refract Ind Ceram 57, 569–573 (2017). https://doi.org/10.1007/s11148-017-0024-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-017-0024-0