Abstract

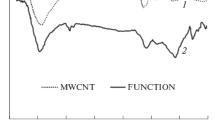

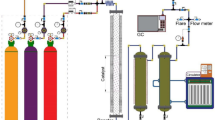

In this work, the nanostructure catalyst of Co–Ru/CNTs is prepared by chemical reduction technique. Then, a set of catalytic experiments are designed and conducted for the Fischer–Tropsch synthesis (FTS) using the synthesized catalyst in a fixed bed reactor. The physical and chemical properties of the support and the synthesized catalyst were determined using the BET, XRD, H2–TPR, TEM, and H2-chemisorption characterization techniques. Based on the alkyl mechanism and using the Langmuir–Hinshelwood–Hougen–Watson (LHHW) isotherm, a kinetic model is developed for FTS. In most of the previous kinetic models, the primary reactions have merely been used, but in the current derivation of the developed kinetic model, the secondary reactions (adsorption, hydrogenation and chain-growth) and re-adsorption of primary olefins at the secondary active sites are considered. The present comprehensive kinetic model is applied for the product distribution such that the rate equations parameters are acquired via optimization. To estimate the kinetic model parameters, FTS was accomplished via a series of tests under the operating conditions as pressure (P): 10–20 bar, temperature (T): 483–513 K, gas hourly space velocity (GHSV): 1400–2400 h−1 and the H2/CO ratio of 1–2. The rationality and significance of the suggested model were checked through the statistical and correlation tests. The obtained results indicated that the outcomes of the current kinetic model were in good agreement with the experimental data. Using the present kinetic model, the average absolute deviations (AAD%) for the prediction of methane, ethylene and heavier hydrocarbons (C5+) formation rates are obtained as 7.06%, 11.57% and 14.74%.

Similar content being viewed by others

Abbreviations

- FTS:

-

Fischer–Tropsch synthesis

- LHHW:

-

Langmuir–Hinshelwood–Hougen–Watson

- CNTs:

-

Carbon nanotubes

- ASF:

-

Anderson–Schulz–Flor

- F-B:

-

Fixed-bed reactor

- TPR:

-

Temperature-programmed reduction

- XRD:

-

X-ray diffractometer

- TEM:

-

Transmission electron microscopy

- RDS:

-

Rate-determining step

- FWHM:

-

Full width half maximum

- R:

-

Universal gas constant (8.314 × 10−5 bar m3/mol K)

- x:

-

Position within the catalyst bed

- T:

-

Reaction temperature (K)

- t:

-

Time consuming for Fischer–Tropsch reaction (s)

- Mw,j :

-

Molecular weight of component j

- P:

-

Productivity (kg) (mass of produced hydrocarbon in liquid phase product)

- F:

-

Molar flow of product in gas phase (mol/s)

- rj :

-

Formation rate of component j (mol/kg s)

- yj :

-

Molar fraction of component j in gas phase

- wj :

-

Weight fraction of component j in the liquid phase

- W:

-

The catalyst weight (kg)

- FCO,in :

-

Molar flow of carbon monoxide in the reactor inlet (mol/s)

- FCO,out :

-

Molar flow of carbon monoxide in the reactor outlet (mol/s)

- B:

-

FWHM of the Co3O4 at diffraction peak of 2θ = 36.8

- MC,out :

-

Mass of output carbon

- MC,in :

-

Mass of input carbon

- NC :

-

Total number of the species

- Fj :

-

Mole flow rates of jth component (mol/s)

- Ri :

-

Rate of ith reaction (mol/kg s)

- NR :

-

Number of total considered reactions

- XCO :

-

CO conversion (%)

- PT :

-

Total pressure in the reactor (bar)

- Pj :

-

Partial pressure of j component (bar)

- O:

-

Objective function of FTS reaction

- K1 :

-

Equilibrium constant for the H2 adsorption on the primary active site

- E:

-

Reaction activation energy (kJ/mol)

- k3 :

-

Rate constant of chain growth in FTS mechanism for primary active site (mol/kg s)

- k3,0 :

-

Pre-exponential factor of chain growth in FTS mechanism for primary active site (mol/kg s)

- k5 :

-

Rate constant of the formation of methane (mol/kg s)

- k5,0 :

-

Pre-exponential factor of the formation of methane (mol/kg s)

- k4 :

-

Rate constant of the formation of paraffins on primary active site (mol/kg s)

- k4,0 :

-

Pre-exponential factor of the formation of paraffins on primary active site (mol/kg s)

- k6 :

-

Rate constant of the formation of olefins (mol/kg s)

- k6,0 :

-

Pre-exponential factor of the formation of olefins (mol/kg s)

- K7 :

-

Equilibrium constant for the CO adsorption on the secondary active site

- k10 :

-

Rate constant for the forward reaction of olefin re-adsorption (mol/kg s bar)

- k10,0 :

-

Pre-exponential factor for the forward reaction of olefin re-adsorption (mol/kg s bar)

- k−10 :

-

Rate constant for the reverse reaction of olefin re-adsorption (mol/kg s)

- k−10,0 :

-

Pre-exponential factor for the reverse reaction of olefin re-adsorption (mol/kg s)

- k11 :

-

Rate constant of chain growth in FTS mechanism for secondary active site (mol/kg s)

- k11,0 :

-

Pre-exponential factor of chain growth in FTS mechanism for secondary active site (mol/kg s)

- k12 :

-

Rate constant of the formation of paraffins on secondary active site (mol/kg s bar)

- k12,0 :

-

Pre-exponential factor of the formation of paraffins on secondary active site (mol/kg s bar)

- ψ:

-

Primary active site on catalyst surface

- θ:

-

Secondary active site on catalyst surface

- σji :

-

Stoichiometric coefficient of jth component in ith reaction

- αn :

-

Chain growth factor of FTS reaction for carbon number (n > 1)

References

Pardo-Tarifa F, Cabrera S, Sanchez-Dominguez M, Boutonnet M (2017) Int J Hydrogen Energy 42:9754–9765

Mohr SH, Wang J, Ellem G, Ward J, Giurco D (2015) Fuel 141:120–135

Abas N, Kalair A, Khan N (2015) Futures 69:31–49

Liu Y, Li Zh, Zhang Y (2016) Reac Kinet Mech Cat 119:457–468

Bukur DB, Todic B, Elbashir NO (2016) Catal Today 275:66–75

Dry ME (1982) J Mol Catal 17:133–144

Mosayebi A, Haghtalab A (2015) Chem Eng J 259:191–204

Farzad S, Haghtalab A, Rashidi A (2013) J Energy Chem 22:573–581

Trepanier M, Dorval Dion CA, Dalai AK (2011) Can J Chem Eng 89:1441–1450

Sari A, Zamani Y, Taheri SA (2009) Fuel Process Technol 90:1305–1313

Todic B, Bhatelia T, Froment GF, Ma W, Jacobs G, Davis BH, Bukur DB (2013) Ind Eng Chem Res 52:669–679

Shiva M, Atashi H, Tabrizi F, Mirzaei AA, Zare A (2013) Fuel Process Technol 106:631–640

Elbashir NO, Roberts CB (2004) Prepr-Am Chem Soc Div Pet Chem 49:57–160

Mogalicherla AK, Elbashir NO (2011) Energy Fuels 25:878–889

Haghtalab A, Nabipour M, Farzad S (2011) Fuel Process Technol 34:546–553

Fabiano A, Fernandes N (2005) Chem Eng Technol 28:1–9

Nabipoor M, Haghtalab A (2013) Chem Eng Commun 200:1170–1186

Zhang X, Liu Y, Liu G, Tao K, Jin Q, Meng F, Wang D, Tsubaki N (2012) Fuel 92:122–129

Qian W, Zhang H, Ying W, Fang D (2013) Chem Eng J 228:526–534

Vaniice AM, Bell AT (1981) J Catal 70:418–432

Vander laan GP, Beenackers ACM (1999) Ind Eng Chem 38:1277–1290

Visconti CG, Tronconi E, Lietti L, Zennaro R, Forzatti P (2007) Chem Eng Sci 62:5338–5343

Shariati J, RamazaniSaadatabadi A, Khorasheh F (2012) J Macromol Sci A 49:749–757

Tavasoli A, Karimi S, Taghavi S, Zolfaghari Z, Amirfirouzkouhi H (2012) J Energy Chem 21:605–613

Karimi S, Tavasoli A, Mortazavi Y, Karimi A (2015) Appl Catal A Gen 499:188–196

Irandoust A, Haghtalab A (2017) Catal Lett 147:2967–2981

Irankhah A, Haghtalab A (2008) Chem Eng Technol 31:525–536

Shariati J, Haghtalab A, Mosayebi A (2019) J Energy Chem 28:9–22

Da Silva JF, Braganca LFFPG, Pais da Silva MI (2018) Reac Kinet Mech Cat 124:563–574

Trépanier M, Tavasoli A, Dalai AK, Abatzoglou N (2009) Appl Catal A Gen 353:193–202

Tavasoli A, Sadagiani K, Khorashe F, Seifkordi AA, Rohani AA, Nakhaeipour A (2008) Fuel Process Technol 89:491–498

Xie Z, Frank B, Huang X, Schlögl R, Trunschke A (2016) Catal Lett 146:2417–2424

Phaahlamohlaka TN, Kumi DO, Dlamini MW, Forbes R, Jewell LL, Billing DG, Coville NJ (2017) ACS Catal 7:1568–1578

Teng BT, Chang J, Zhang CH, Cao DB, Yang J, Liu Y, Guo XH, Xiang HW, Li YW (2006) Appl Catal A 301:39–50

Lente G (2015) Deterministic kinetics in chemistry and systems biology. Springer, New York

Mosayebi A, Abedini R (2017) Int J Hydrogen Energy 42:27013–27023

Chang J, Bai L, Teng B, Li Y (2007) Chem Eng Sci 62:4983–4991

Todic B, Ma W, Jacobs G, Davis BH, Bukur DB (2014) Catal Today 228:32–39

NakhaeiPour A, Housaindokht MR (2013) J Nat Gas Sci Eng 14:204–210

Rao PVR, Shafer WD, Jacobs G, Martinelli M, Sparks DE, Davis BH (2017) RSC Adv 7:7793–7800

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Haghtalab, A., Shariati, J. & Mosayebi, A. Experimental and kinetic modeling of Fischer–Tropsch synthesis over nano structure catalyst of Co–Ru/carbon nanotube. Reac Kinet Mech Cat 126, 1003–1026 (2019). https://doi.org/10.1007/s11144-019-01535-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-019-01535-7