Abstract

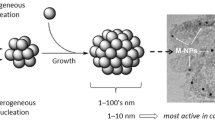

Five morphologically different nanostructured molybdenum disulfide (MoS2) samples were prepared, namely: nanoparticles, nanorods, nanoplatelets, nanoflowers and porous. These structures were characterized using X-ray diffraction and scanning electron microscope analyses. Afterwards, the up gradation of heavy oil was carried out in the presence of aforementioned nanostructures of molybdenum disulfide as catalysts. The results of catalytic and non-catalytic hydro-processing were compared. It was found that catalytic hydro-processing, due to lower sulfur contents, led to a more efficient and environmental friendly procedure as compared to non-catalytic hydro-processing. Furthermore, aromaticity, aromaticity condensation and branchiness index were also determined. In addition, nuclear magnetic resonance analyses were presented for the product of catalytic hydroprocessing. The nanoparticle morphology of molybdenum disulfide, catalyst, exhibited better result, due to its higher surface area, as compared to other morphologies of molybdenum disulfide catalysts, i.e., nanorods, nanoplatelets nanoflowers and porous structures.

Similar content being viewed by others

Abbreviations

- BI:

-

Branching index

- CT :

-

Total carbon

- f A :

-

Aromaticity

- HT :

-

Total hydrogen

- HA :

-

Aromatic hydrogen

- HAU/CA :

-

Aromaticity condensation

- Hα :

-

Aliphatic hydrogen on Cα to aromatic ring

- Hβ :

-

Aliphatic hydrogen on Cβ and CH2, CH beyond the Cβ to aromatic ring

- Hγ :

-

Aliphatic hydrogen on Cγ and CH3 beyond the Cγ to aromatic ring

References

Tian KP, Mohamed AR, Bhatia S (1998) Catalytic upgrading of petroleum residual oil by hydrotreating catalysts: a comparison between dispersed and supported catalysts. Fuel 11:1221–1227

Speight JG (2014) The chemistry and technology of petroleum. CRC Press, Boca Raton

Purón H, Pinilla JL, Berrueco C, Montoya de la Fuente J, Millán M (2013) Hydrocracking of Maya vacuum residue with NiMo catalysts supported on mesoporous alumina and silica–alumina. Energy Fuel 7:3952–3960

Uchisawa J, Tango T, Murakami T, Nakagawa H, Hara S, Nanba T, Obuchi A (2013) Diesel hydrocarbon oxidation over platinum on mesoporous silica doped with secondary component metals via a sol–gel methodology. Reac Kinet Mech Cat 2:359–370

Rana MS, Sámano V, Ancheyta J, Diaz J (2007) A review of recent advances on process technologies for upgrading of heavy oils and residua. Fuel 9:1216–1231

Parkhomchuk EV, Lysikov AI, Okunev AG, Parunin PD, Semeikina VS, Ayupov AB, Trunova VA, Parmon VN (2013) Meso/macroporous CoMo alumina pellets for hydrotreating of heavy oil. Ind Eng Chem Res 48:17117–17125

Speight JG (1998) Petroleum chemistry and refining. Taylor & Francis, Washignton DC

Rudrake A, Karan K, Horton JH (2009) A combined QCM and XPS investigation of asphaltene adsorption on metal surfaces. J Colloid Interface Sci 1:22–31

Chianelli R (1984) Fundamental studies of transition metal sulfide hydrodesulfurization catalysts. Catal Rev Sci Eng 3–4:361–393

Rivera-Muñoz E, Alonso G, Siadati M, Chianelli R (2004) Silica gel-supported, metal-promoted MoS2 catalysts for HDS reactions. Catal Lett 3–4:199–204

Yang Y, Luo HA, Tong G, Smith KJ, Tye CT (2008) Hydrodeoxygenation of phenolic model compounds over MoS2 catalysts with different structures. Chin J Chem Eng 5:733–739

Iwata Y, Araki Y, Honna K, Miki Y, Sato K, Shimada H (2001) Hydrogenation active sites of unsupported molybdenum sulfide catalysts for hydroprocessing heavy oils. Catal Today 2:335–341

Iwata Y, Sato K, Yoneda T, Miki Y, Sugimoto Y, Nishijima A, Shimada H (1998) Catalytic functionality of unsupported molybdenum sulfide catalysts prepared with different methods. Catal Today 1:353–359

Bellussi G, Rispoli G, Molinari D, Landoni A, Pollesel P, Panariti N, Millini R, Montanari E (2013) The role of MoS2 nano-slabs in the protection of solid cracking catalysts for the total conversion of heavy oils to good quality distillates. Catal Sci Technol 1:176–182

Jaramillo TF, Jørgensen KP, Bonde J, Nielsen JH, Horch S, Chorkendorff I (2007) Identification of active edge sites for electrochemical H2 evolution from MoS2 nanocatalysts. Science 5834:100–102

Pourabbas B, Jamshidi B (2008) Preparation of MoS2 nanoparticles by a modified hydrothermal method and the photo-catalytic activity of MoS2 TiO2 hybrids in photo-oxidation of phenol. Chem Eng J 1:55–62

Afanasiev P, Xia G-F, Berhault G, Jouguet B, Lacroix M (1999) Surfactant-assisted synthesis of highly dispersed molybdenum sulfide. Chem Mater 11:3216–3219

Raybaud P, Hafner J, Kresse G, Kasztelan S, Toulhoat H (2000) Structure, energetics, and electronic properties of the surface of a promoted MoS2 catalyst: an ab initio local density functional study. J Catal 1:128–143

Schweiger H, Raybaud P, Toulhoat H (2002) Promoter sensitive shapes of Co (Ni) MoS nanocatalysts in sulfo-reductive conditions. J Catal 1:33–38

Bokhimi X, Toledo J, Navarrete J, Sun X, Portilla M (2001) Thermal evolution in air and argon of nanocrystalline MoS2 synthesized under hydrothermal conditions. Int J Hydrog Energy 12:1271–1277

Li W-J, Shi E-W, Ko J-M, Chen Z-Z, Ogino H, Fukuda T (2003) Hydrothermal synthesis of MoS2 nanowires. J Cryst Growth 3:418–422

Wilcoxon J, Newcomer P, Samara G (1997) Synthesis and optical properties of MoS2 and isomorphous nanoclusters in the quantum confinement regime. J Appl Phys 12:7934–7944

Li Q, Newberg J, Walter E, Hemminger J, Penner R (2004) Polycrystalline molybdenum disulfide (2H-MoS2) nano-and microribbons by electrochemical/chemical synthesis. Nano Lett 2:277–281

Sano N, Wang H, Chhowalla M, Alexandrou I, Amaratunga GA, Naito M, Kanki T (2003) Fabrication of inorganic molybdenum disulfide fullerenes by arc in water. Chem Phys Lett 3:331–337

Vollath D, Szabo D (1998) Synthesis of nanocrystalline MoS2 and WS2 in a microwave plasma. Mater Lett 3:236–244

Zach M, Inazu K, Ng K, Hemminger J, Penner R (2002) Synthesis of molybdenum nanowires with millimeter-scale lengths using electrochemical step edge decoration. Chem Mater 7:3206–3216

Li Q, Walter E, Van der Veer W, Murray B, Newberg J, Bohannan E, Switzer J, Hemminger J, Penner R (2005) Molybdenum disulfide nanowires and nanoribbons by electrochemical/chemical synthesis. J Phys Chem B 8:3169–3182

Speight JG (2004) New approaches to hydroprocessing. Catal Today 1:55–60

Burriel-Marti F, Vidán AM (1962) Precipitation from homogeneous solution: precipitation of molybdenum as sulfide with thioacetamide. Anal Chim Acta 26:163–167

Tian Y, Zhao J, Fu W, Liu Y, Zhu Y, Wang Z (2005) A facile route to synthesis of MoS2 nanorods. Mater Lett 27:3452–3455

Wang Y, Chen Y, He J, Li P, Yang C (2010) Mechanism of catalytic aquathermolysis: influences on heavy oil by two types of efficient catalytic ions: Fe3+ and Mo6+. Energy Fuel 3:1502–1510

Chen Y, Yang C, Wang Y (2010) Gemini catalyst for catalytic aquathermolysis of heavy oil. J Anal Appl Pyrolysis 2:159–165

Chen Y, Wang Y, Wu C, Xia F (2008) Laboratory experiments and field tests of an amphiphilic metallic chelate for catalytic aquathermolysis of heavy oil. Energy Fuel 3:1502–1508

Mochida I, Zhao XZ, Sakanishi K (1988) Catalyst deactivation during the hydrotreatment of asphaltene in an Australian brown coal liquid. Fuel 8:1101–1105

Melo Faus F, Grange P, Delmon B (1984) Influence of asphaltene deposition on catalytic activity of cobalt molybdenum on alumina catalysts. Appl Catal 2:281–293

Hauser A, Bahzad D, Stanislaus A, Behbahani M (2007) Thermogravimetric analysis studies on the thermal stability of asphaltenes: pyrolysis behavior of heavy oil asphaltenes. Energy Fuel 1:449–454

Martinez MT, Benito AM, Callejas MA (1997) Thermal cracking of coal residues: kinetics of asphaltene decomposition. Fuel 9:871–877

Nassar NN (2010) Asphaltene adsorption onto alumina nanoparticles: kinetics and thermodynamic studies. Energy Fuel 8:4116–4122

Maity S, Ancheyta J, Marroquín G (2010) Catalytic aquathermolysis used for viscosity reduction of heavy crude oils: a review. Energy Fuel 5:2809–2816

Acknowledgments

The technical and financial support of Korea Science and Engineering Foundation (KOSEF) is highly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bano, S., Ahmad, S.W., Woo, S.I. et al. Heavy oil hydroprocessing: effect of nanostructured morphologies of MoS2 as catalyst. Reac Kinet Mech Cat 114, 473–487 (2015). https://doi.org/10.1007/s11144-014-0822-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-014-0822-z