Abstract

The dramatically increasing nitrogen fertiliser prices and growing environmental awareness emphasise the need to optimise machine operability to avoid double overlapping of the target dose rate in different field units, including headlands and field bodies, to be more congruent with satellite-based nitrogen prescription maps. However, the map grids frequently do not correspond with farmers’ management practices, specifically machine operability. To this end, this study develops an algorithm that subdivides any given field into operable units by considering pneumatic spreaders based on the actual tramline on the field and placing the operable units along with this. The newly developed algorithm allows ex-ante specification of the required fertiliser amount. It shows how well such techniques can implement an optimised application map supported by the statistical information for each field unit. Uniform fertilizer application can further be compared with variable rate application (VRA) as well as machinery with and without section control, allowing the identification of areas with the greatest deviation and the excess amount of nitrogen applied. A more precise nitrogen application on both homogeneous or heterogeneous field units saves nitrogen and decreases the negative environmental impact.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The dramatically increasing nitrogen fertiliser prices and growing environmental awareness require a more precise nitrogen application to different field units, including headlands and interior parts of the fields, and more targeted applications to different field zones varying in productivity. Therefore, nitrogen application to fields must be optimized on both homogeneous and heterogeneous fields. Field contours frequently vary, necessitating consideration in fertiliser application, as well. The overlapping of target dose rates should be avoided, and heterogeneous fields should be fertilised according to site-specific yield potentials to target the nitrogen application to management zones and avoid nitrogen losses harming the environment (Balafoutis et al., 2017; Bongiovanni & Lowenberg-Deboer, 2004; English et al., 1999; Geesing et al., 2014; Jin et al., 2019).

Such strategies vary depending on the current fertiliser practice. Driven by high yield expectations, farmers, particularly in the highly productive regions of West Europe, tend to over-apply nitrogen; hence, strategies must be optimized. Massive problems exist in Germany and other European regions with intensive agriculture (Schuster et al., 2022). This requires avoiding overlapping nitrogen target dose rates in headlands and field bodies but not applying outside the field boundaries and improved site-specific fertiliser application strategies respecting productivity differences. No strict consensus on the latter exists. Recommendations on heterogeneous fields differ and include, for example, redistributing nitrogen by applying less nitrogen to the less productive, environmentally more vulnerable zones for the sake of the more productive zones but also increased application to less productive zones (Guerrero & Mouazen, 2021, Yara Deutschland, 2018). However, long-term field evaluation of different strategies has shown that nitrogen applications should be markedly reduced in less fertile zones. There may be even occasionally a potential for reducing nitrogen application in the more fertile zones considering that nitrogen applications still tend to be overly high and frequently overpass the specific crop demand (Ebertseder et al., 2005; Schmidhalter et al., 2008; Mittermayer et al., 2021). Nitrogen applications in heterogeneous fields should also be crop-demand oriented to align with the good code of agricultural practice. This is supported by the need to decrease further the excessive nitrogen budgets prevailing in many countries and the negative impacts of excessive nitrogen application on the environment, including groundwater, air quality, and health (Wang and Li, 2019; Hu & Schmidhalter 2021). The unsatisfactory groundwater quality status in nitrate-sensitive zones has resulted in several West European countries adopting legislative measures that require reduced nitrogen application even below the expected crop nitrogen demand in line with the Nitrate Directive requirements (BMEL 2020, 2017).

A further approach to reducing the fertiliser amount is to divide the working width into several sections, which reduces areas (with unwanted overlapping of target doses) receiving excessive fertiliser (Guerrero & Mouazen, 2021; Shockley et al., 2012).

Subdividing a field into management zones is challenging and frequently needs the support of service providers, leading farmers to rely on them. With the advancement of freely available Sentinel satellite data (esa, 2022a) as part of the Copernicus mission in 2016, a widespread offer and usage of such information can be observed. In rare cases, farmers will download the information alone, but most frequently, this will be offered and performed by commercial service suppliers. In Germany, for example, several commercial service providers are already offering varying solutions to farmers, including biomass maps and yield potential maps of individual fields (e.g., AGRAVIS, 2021; VISTA, 2019) or fertiliser application maps (Atfarm, 2021; geo-konzept, 2021; KleffmanDigital, 2021; Solorrow, 2021; VISTA, 2019).

Beyond the fact that the information offered for the same field may vary among providers, requesting strengthened efforts to assess the information critically, pixel- or management unit-based information is based on grids derived from satellite or drone data. However, these uniform grids are often unrelated to the fertiliser spreader technology used by farmers; hence, the boundaries of fertilisation zones and working widths will not frequently correspond.

Approaches that address the operability of these application maps with the application technique already exist (Griepentrog et al., 2007; Tisseyre & McBratney, 2008). In some cases, even the main tramline is considered here with application errors (Leroux et al., 2017; Roudier et al., 2011; Griepentrog, 1997) and additionally supplemented by the overlap representation at the headland (Zandonadi et al., 2011). However, it has not been investigated how accurately an application map can be implemented using the existing technique when considering the overlap at the first round along the field boundary and the change between the headland and the field interior. The previous attempts did not yet provide farmers with a map that allowed them to make the best use of his machine. So far, specific indices [which are not to be confused with spectral indices like the NDVI (ROUSE et al. 1974)] that use input parameters like working widths and management zones have been calculated to determine whether or not VRA is recommendable (Griepentrog et al., 2007; Leroux et al., 2017; Roudier et al., 2011) or which percentage overlap exists between the headland and the inner area of the field (Zandonadi et al., 2011).

This is particularly noteworthy considering that Bavaria, the largest agricultural federal state of Germany, where exemplary field sites have been chosen for this study, only has 1.64 ha of average field size (Bayerische Landesanstalt für Landwirtschaft 2018). The 95% field size is smaller than 5 ha (Fig. 1); thus, the proportion of headlands is significantly larger compared to areas with larger field sizes (e.g., in East Germany or some East European countries), and many of them do not have regular field shapes.

Field size distribution in the German federal state of Bavaria (based on Bayerische Landesanstalt für Landwirtschaft 2018)

Using prescribed maps offered by service providers that do not match the given field subdivisions, it does not become evident how the recommended fertiliser application maps are derived and how they suit the fertiliser spreader technology on a given farm. With common machinery software, the weighted average of the entire working width is generally not created because only values from the exact position of the tractor are used (Sharipov et al., 2021).

In the present work, we focus on advanced spreaders, such as pneumatic spreaders or field sprayers, which allow precise site-specific application in both lateral and longitudinal distribution. In contrast, disc spreaders require a double overlapping to optimize the lateral distribution but also have a significant positional gap in the longitudinal position. The common overlapping required for disc spreaders is to be distinguished from the undesirable double overlapping of the target dose rate.

Seen that satellite information may be offered in 10 m pixel resolution, this represents a challenge for common working widths, particularly of centrifugal spreaders, but also pneumatic spreaders or sprayers how to optimize the congruence of such satellite information with common working widths. In this work, we concentrate on pneumatic spreaders or sprayers but will briefly also discuss the implications and optimizations for advanced disc spreaders offering a more distinct lateral distribution. For this work, we have chosen a pneumatic spreader or sprayer with a 27 m working width, allowing it to switch on and off in 3 m units. It is important to remember, as outlined above, that the positional information of 10 m satellite pixels does generally not match available working widths of fertiliser spreaders, is frequently not aligned along the tramline, and does, particularly along the field boundaries, often include only fractions of pixels which are often also irregularly shaped. To the best of our knowledge, the optimization of the congruency of the resolution of satellite-based fertiliser map information with common working widths of fertiliser spreaders and the option to control boom sections as well as the ex-ante quantification of the actual amount of fertiliser applied has not been addressed and represents the goal of this work. We further address six scenarios, with and without section control and including, for both cases, a uniform nitrogen application, a site-specific fertiliser application with a redistribution strategy (from the less fertile to the more fertile zones without changing the total application rate), and a variable rate application by reducing the application in the less favorable zones and keeping constant in the more productive zone in line with a demand-oriented application, thus overall reducing the applied amount of nitrogen. The potential to increase the precision in nitrogen application is demonstrated, and possible savings are indicated for five fields.

Materials and methods

Experimental fields

The investigated fields are in the federal state of Bavaria, Germany, and are managed following standard practices. These fields are located in Neuburg District on the Danube. Moderately heterogeneous fields of farmers with winter wheat were used for this study. Farm fields belonging to the Technical University of Munich located in Freising were also used. Figure 2 presents the field maps with their contours and sizes. Field 3 has variable soil types (more or less sandy), fields 3 and 4 have changing topography, and field 5 has backfilled soil in some parts of the field.

Fertiliser application maps

The fertilisation maps were based on satellite-based NDVI images for the respective fields. Figure 3 shows an exemplary field map. Reflectance values were obtained from the SENTINEL-2 mission of the European Space Agency (esa, 2022b). Satellite data were preferred over airplane or unmanned aerial vehicle reflectance information because of their widespread use and lower cost (Sozzi et al., 2021). Their spatial accuracy of 10 m for the necessary bands for calculating the NDVI is also sufficient for fertilisation.

The NDVI images were obtained shortly before or on the date of the second fertiliser application at BBCH 32. These dates were April 28, 2021, for field 1; April 26, 2020, for field 2; April 26, 2021, for field 3; April 21, 2020, for field 4; and April 16, 2020, for field 5. Two years were used because winter wheat was not grown in all fields in the same year. The different days in the same year are due to the different cloud cover on the fields.

In this work, six scenarios in total were investigated. We evaluated the usage of no section control or section control and, for both cases, three nitrogen application strategies (uniform application and two variable rate applications, termed VRA 1 and VRA 2). In the uniform strategy, 70 kg N/ha was applied. The VRA 1 strategy included a redistribution strategy (from the less fertile to the more fertile zones without changing the total application rate), and it was varied to be within ± 20 kg N/ha of the uniform application rate, and VRA 2 consisted of a demand-oriented strategy by reducing the application in the less favorable zones and keeping the applied nitrogen amount constant in the most productive zones (leveling at 70 kg N/ha comparable to the amount applied by the uniform application), thus overall reducing the applied amount of nitrogen.

Pixel-specific N fertilisation values were determined; hence, specific management zones were not created. This allowed a weighted average for later allocation to the operable subunits using the existing machinery width, considering that the previous zoning would affect the accuracy (Fig. 3).

Software

Data processing was performed using self-written programs in Python (Python Software Foundation, 2022) with Jupyter notebook (Project Jupyter, 2022). The packages used for processing the field boundaries were GeoPandas (Jordahl, 2014) and Shapely (Sean Gillies, 2007). The satellite data were downloaded using the Earth Engine (google 2022) and eeconvert (Hofste, 2018) packages. The pandas (McKinney, 2010), NumPy (Oliphant, 2006), and scikit-learn (Pedregosa et al., 2011) packages were used for further data processing. Lastly, Matplotlib (Hunter, 2007) visualized the data and results.

Input parameters

The field contour, working width, and changeover distance served as the input parameters for the field map creation, like those reported by Tisseyre & McBratney (2008) and Roudier et al., (2011). Individually switchable boom sections and the main tramline were also added. The changeover distance represents the distance the fertiliser spreader does not change the application rate. The distance the machine needs to adjust the application rate, termed positional gap (Griepentrog & Persson, 2001; Fulton et al., 2005), was not taken into account for reasons of simplicity, and an immediate change in the application rate was assumed.

The number of boom sections is defined as how often the working width can be subdivided to switch individual boom sections on and off, for example, in narrow tracks. The main tramline indicates the line on which the farmer drives in his field apart from the round along the field boundary.

The input parameters used to create the field maps refer to any pneumatic spreader with a working width of 27 m and nine boom sections. A pneumatic spreader was chosen because it allows more precise switch-on and offs than a disc spreader. The application rate remained the same over the entire working width. The changeover distance was set to 20 m, and the switch-on and switch-off points of the boom sections were considered optimally set. A treatment considering no subdivision of the working widths into boom sections was also evaluated to outline the possible advantages of using boom sections.

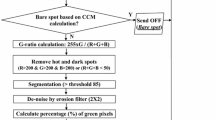

Procedure defining operable subunits

The field contour was first divided into individual tramlines. For this purpose, the contour was divided into individual straight lines and reassembled depending on the selected curve angle at which the curve can no longer be driven, and a new line begins. The main tramline was also selected from these tramlines because it is important for the subsequent field subdivision (Fig. 4).

The field was divided into a round along the boundary and the inner part. Accordingly, the boundary lines were shifted inwards by the working width. The field was then divided at this inner boundary line (Fig. 5).

The final operable subunits were separately created for the two parts of the field, the round along the field boundary and the body part.

Creation of operable subunits inside the field

The field was first divided into strips by choosing the selected working width and using parallels of the main travel line to divide the inner part into operable subunits. These working widths were cut into smaller strips using the selected number of boom sections. Each strip corresponds to the selected working width divided by the number of boom sections. The individual strips of the boom sections were cut again at a 90° angle to simulate the switch off and on of the machine when entering the inner field body from the round along the field boundary and vice versa.

The strips belonging to one working width were then reassembled into one. This reassembled strip was subdivided into the final individual operable subunits with the selected changeover distance. The cutting process was continued on the opposite side of the previous working width to simulate the travel process (Fig. 6).

Creating operable subunits in the round along the field boundary

When creating operable subunits in the round along the field boundary, the field boundary was shifted inward by the working width. The area between the actual and shifted field boundary formed a frame with the thickness of a working width (Fig. 5 right, remaining blue area). For this frame, the creation of the final operable subunits was like that of the operable subunits inside the field (previous subsection). In contrast, no parallels of a line were created here. All tramlines were used to drive once around the field. The assumed travel direction was counterclockwise because the common boundary spreading systems on disk spreaders can either spread on both sides of the boundary (Amazone; RAUCH Landmaschinenfabrik GmbH) or only on the right side (Bogballe, 2019), allowing most farmers to work in this direction. This step is necessary to use the approach for disc spreaders and not only for pneumatic spreaders.

After that, the finalised operable subunits of the round along the field boundary were merged with those of the interior of the field. The operable subunit creation was then finally completed (Fig. 7).

Comparison with the given fertilisation maps

Next, the fertilisation map and the operable subunits created in the previous section were overlaid to assess whether and how well the fertilisation map can be addressed using the chosen technology. The weighted average (Eq. 1) of all fertiliser values within each operable subunit was calculated to determine the specific application rate for the given operable subunits.

\(\stackrel{-}{x}\) is the weighted average, n the number of pixels in the operable subunit, \({x}_{i}\) the corresponding nitrogen application rate for every pixel and \({w}_{i}\) the size of the intersection of the pixel and the operable subunit. This step was necessary because different fertiliser amounts may be recommended within an operable subunit. Deciding on the dominant fertilising amount, as described by Leroux et al., (2017) and Roudier et al., (2011), was no longer necessary with today’s technology because modern fertiliser spreaders no longer have such large intervals between differing fertilisation rates.

Subsequently, the root mean square error (RMSE, Eq. 2) was determined for each operable subunit for both the uniform and VRA treatments.

\({RMSE}_{os}\) is the root-mean-square error for each operable subunit, \(\hat{y}_{i}\) the weighted mean application rate in the chosen operable subunit, \({y}_{i}\) the application rate of the respective NDVI pixels in the operable subunit. \(N\) is the number of different Sentinel-2 pixels in the operable subunit, \({a}_{\text{i}}\) is the number of square meters multiplied by 100 in each pixel overlaid with the operable subunit and \({\text{a}}_{\text{O}\text{S}}\) is the number of square meters in the operable subuinit multiplied by 100. This last step is necessary to account for the different-sized pixel overlays in the operable subunit.

The created operable subunits allow calculating the applied amount of fertiliser for the different treatments. Due to the overlap on the round along the field boundary and the non-parallel field boundaries, the actual amount of applied fertiliser will not correspond with that of the pre-set fertiliser amount, even with uniform fertiliser application, but will mostly be higher.

In short, a total of six variants were compared with each other: (i) uniform application without section control, (ii) uniform application with section control, (iii) VRA 1 without section control, (iv) VRA 1 with section control, (v) VRA 2 without section control and (vi) VRA 2 with section control.

Results

Figure 8 illustrates the NDVI values of the selected experimental fields for the previously indicated dates. The mean NDVI values for fields 1–5 were 0.77, 0.81, 0.57, 0.68, and 0.79, respectively. The respective coefficients of variations were 4%, 5%, 13%, 8%, and 7%, respectively, indicating overall moderate heterogeneity of the investigated fields.

Figure 9 illustrates the fertilisation map, fertiliser amounts assigned to the created operable subunits, and corresponding RMSE values for the uniform and the VRA 1 treatment without section control. Fig. 10 illustrates this for the uniform and VRA 1 treatment using section control.

Fertilisation map, fertiliser amounts assigned to the created operable subunits and corresponding RMSE values for the uniform and VRA 1 treatment without section control: (a) pixel-oriented fertilisation map based on the NDVI map using an average N application rate of 70 kg/N ha; (b) overlay of the created operable subunits without section control and the corresponding fertilisation map derived from Fig. 9a; (c) RMSE and average RMSE values of 10.3 kg N/ha using a uniform application, with an applied amount of 76.0 kg N/ha; (d) RMSE and average RMSE values of 8.6 kg N/ha using VRA 1, with an applied amount of 75.7 kg N/ha

Fertilisation map, fertiliser amounts assigned to the created operable subunits, and corresponding RMSE values for uniform and VRA 1 treatments with nine boom sections: (a) Pixel-oriented fertilisation map based on the NDVI map using an average N application rate of 70 kg/N ha; (b) overlay of the created operable subunits with section control and the corresponding fertilisation map derived from Fig. 10a; (c) RMSE values and average RMSE value of 6.1 kg N/ha using a uniform application, with an applied amount of 71.0 kg N/ha; (d) RMSE values and average RMSE value of 4.0 kg N/ha using a VRA 1, with an applied amount of 71.0 kg N/ha.

Using a 27 m working width by choosing no subdivision into boom sections and adopting a uniform N application of 70 kg N/ha (Fig. 9) resulted in an RMSE value of 10.3 kg N/ha, which indicated that, on average, each operable subunit deviated from the fertilisation map by 10.3 kg N/ha. This error was reduced to 8.6 kg N/ha by switching to VRA 1. The amount of nitrogen applied in both treatments was slightly below 76 kg N/ha, 6 kg N/ha more than planned.

Figure 10 illustrates the same parameters presented in Fig. 9 but using nine boom sections. This option reduced the RMSE compared to the uniform treatment by approximately 4 kg N/ha to 6.1 kg N/h a. In addition, the actual amount of nitrogen applied decreased to 71.0 kg N/ha. The error became even smaller with the VRA 1 treatment using section control. The RMSE was 4.0 kg N/ha, decreasing thus by over 4.5 kg N/ha. The amount of nitrogen applied amounted to 71.0 kg N/ha and was very close to the prescribed one.

The results for VRA 2 are indicated in Table 1.

Table 1 presents the RMSE values, and the actual amounts of nitrogen applied using uniform or VRA treatments for different fields. The VRA treatments always reduced the RMSE values. Meanwhile, the actual amount of nitrogen applied hardly differed between the VRA 1 and the uniform treatment.

Table 2 illustrates how the RMSE values and the applied amount of nitrogen were reduced using section control and compares it to Table 1. Consequently, the applied amount of nitrogen became significantly closer to the planned values, and the error was comparably reduced.

Overall, the VRA 1 treatment, with and without section control, did not decrease the applied amount of nitrogen (ranging from 0.0 to 0.3 kg N/ha) as compared to the uniform treatment, whereas the RMSE values were decreased but to a variable degree depending on the investigated field site (from 0.3 up to 3.7 kg N/ha). This was different for the VRA 2 treatment compared to the uniform treatment, where the applied amount of nitrogen (ranging from 1.2 to 3.9 kg N/ha) together with the RMSE values (between 1.4 and 5.3 kg N/ha) was decreased.

Figure 11 shows the difference between a redistribution strategy of fertilizer as used in the VRA 1 treatment versus a reduction of fertilizer as adopted in the VRA 2 treatment.

Discussion

In this work, an algorithm was developed to improve the congruency of satellite-based fertiliser map information with field-operable units and was evaluated for advanced fertiliser application technologies using a pneumatic spreader. Optimisation potentials of section control and variable rate applications were further investigated.

Advantages of using boom sections

With only slight modifications, the new algorithm will allow the creation of adapted operable subunits for different working widths, also taking into account the number of available boom sections, but is illustrated here for a pneumatic sprayer having nine boom sections.

Comparing the application without boom sections and nine boom sections revealed a distinct reduction of the applied nitrogen amount (Table 2). The nitrogen amounts applied were also found to correspond better with the planned application. The usage of boom sections reduces the overlap in the round along the field boundary and wedges due to narrowing tracks and, consequently, the amount of nitrogen applied, which is economically and ecologically desirable. Fertiliser savings will further be augmented by increasing the number of boom sections and/or reducing the working width on fields with no rectangular shape by reducing the overlapping of the target dose rates in such areas. These advantages have already been demonstrated in fertilisation, crop protection measures, and seeding operations (Guerrero & Mouazen, 2021; Runge et al., 2014; Shockley et al., 2012). This positive effect is greater with irregularly shaped fields, especially if they are small and have a high percentage of the headland.

Advantages of using variable rate applications

The new algorithm allows for a better match of satellite map-based fertiliser application with field operable units by using pneumatic spreaders and implicitly also sprayers. Optimized values from VRA and uniform fertilisation treatments assigned to these zones made it possible to compare how much the application in each operable subunit deviated from the planned application map.

The precision in nitrogen application was increased by both VRA strategies compared to the uniform management, as shown by decreased RMSE values (Table 1). This can be attributed to a more needs-based fertiliser distribution over the entire field and is advantageous because plants are supplied with nitrogen according to their specific needs in the given field sites. Accordingly, over-fertilisation within partial field zones with less vigorous plant growth is reduced and decreases potential nitrogen losses contributing to groundwater contamination. The benefits of site-specific N fertilisation on N use efficiency and the environment have already previously been demonstrated (Balafoutis et al., 2017; Bongiovanni & Lowenberg-Deboer, 2004; Ebertseder et al., 2003, 2005; Geesing et al., 2014; Raun et al., 2002; Schmidhalter et al., 2008; Stamatiadis et al., 2017; Vizzari et al., 2019).

However, the amount of nitrogen applied did not significantly change when the VRA 1 fertilisation strategy was used since a simple redistribution was adopted, meaning that the overall application would not change. In contrast, considering that frequently current applications are over-optimal (Ebertseder et al., 2005; Schmidhalter et al., 2008), adopting a decreased application to the more fertile zones and decreased application to the less fertilised zones reduced the total amount of fertiliser applied (VRA 2). However, a simple redistribution may also benefit plant growth and contribute to environmental improvements since plant growth may be enhanced in the more fertile zones and be accompanied by increased nitrogen uptake.

The higher reduction of the applied amount in the VRA 2 compared to the VRA 1 treatment is because the average amount of applied nitrogen in the VRA 2 treatment was reduced compared to the VRA 1 treatment due to the cut-off at 70 kg N/ha (Table 4). This reduction also caused larger changes in the RMSE values since many adjacent areas require exactly these 70 kg, as illustrated in Fig. 11.

Ex-ante quantification of the actual amounts of nitrogen fertiliser to be applied

As a novelty, this report presents an ex-ante analysis of the amount of fertiliser applied and allows the calculation of the exact amount of fertiliser needed for a given field. Until now, overlaps have only been determined as percentage values (Shockley et al., 2012; Zandonadi et al., 2011). The actual amounts of applied fertiliser were determined only after the completed fertiliser application as a post-hoc analysis by dividing the fertilised amount by the area.

Positioning of the formed operable subunits

A particular feature of this approach is the shape and positioning of individual operable subunits that do not correspond with the zoning of a field or a uniform grid. They represent the actual units through which the machine passes and where the application rate can be changed. Such an approach combined with boom sections has not been previously reported. Previous reports have either described an index that evaluates the possibility of variable rate application (Tisseyre & McBratney, 2008) or placed a uniform grid within the working width and the switching distance over the field (Leroux et al., 2017), which do not correspond with the actual cultivation and do not include the round along the field boundaries. Griepentrog (1997) described similar operable subunits for application within a field but did not address the headland and the associated overlap.

Most commercial offers by manufacturers provide only a ready-made map for fertilisation that corresponds with field zoning but do not consider machine-specific field operable units (geo-konzept, 2021; Solorrow, 2021; VISTA 2019). Transferring information from these maps into a fertilisation decision must be made by the farmer or the agricultural equipment manufacturer. Various inaccuracies might occur here; for example, in the conversion of the specified fertiliser quantities in the current area to an output quantity that is applied (e.g., many ISO bus terminals do not calculate the weighted average for all information at hand as regards pixel-oriented fertilisation specified for the working width but use only the value at the actual tractor position).

This feature of the approach can be used not only with new advanced technology but also partly with older application technology that supports VRA. Creating the weighted average of all recommended N values of the application map for the individual operable subunits leads to an application rate closer to the application map, no matter at which point of the working width the machine reads the application value.

Outlook

This approach can also partly be adopted by disc spreaders allowing to some degree for a partial variation in the lateral application of fertiliser. When looking at new disc spreaders, the option is now to gradually reduce the working width from either the left or right side (Bogballe, 2019b). Although this is not as sharp a distinction as with pneumatic spreaders, it would also already lead to a significant savings potential and could be used by more farmers due to the lower investment costs.

In analogy to the fertilisation map, this procedure could be adopted for any application map, including seeding, growth regulator, or pesticide application and harvesting.

In future work, it will be interesting to consider different parameters in varying the working width and the number of boom sections, along with the economic costs and benefits. Lower working widths and/or a higher number of boom sections could lead to enhanced fertiliser savings but increase the application and machinery costs. The difference between the described pneumatic fertiliser spreader and a disk spreader or even a more advanced pneumatic fertiliser spreader with different application rates per boom section and sub-meter plant information would be interesting to investigate the impact of the positional gap on the distribution accuracy. This work did not yet consider the positional lag, which, however, has very recently significantly been reduced in advanced pneumatic spreaders, amounting to approximately 8 m at the outermost exhaust manifold of a 27 m boom and decreasing linearly to 3 m at the middle outlet manifold when driving at 12 km/h (personal communication Romain Muckensturm, Rauch company, 2022), thus being reduced compared to previous reports (Griepentrog and Petterson, 2001; Fulton et al., 2005).

Conclusion

This study developed a new algorithm that allows dividing a field into manageable subunits by adopting different working widths and boom section numbers depending on the used machinery. As a result, an ordinary application map with operable subunits in a regular raster or management zone can be converted to one manageable with the given machinery. The operable subunits are suited to the tramlines and working width, several boom sections, and changeover distance of the machinery used.

With this new approach, the applied amount of fertiliser can be determined ex-ante, contributing to improved planning. Operable subunits better matching the actual application also allow a more accurate fertiliser application on the field because the weighted average of pre-planned fertiliser amounts can be calculated separately for each operable subunit. Likewise, this algorithm can be applied on the supplier side to provide farmers with fertiliser maps tailored to their farm technology.

The approach further allows determining whether there is a potential to save fertiliser by dividing the working width into several boom sections, which is desirable from both economic and environmental points of view.

References

AGRAVIS (2021). AGRAVIS Digital GmbH. https://www.netfarming.de/de/netfarming_de/nf_produkte/managementzonenkarte/standard_240.html. last accessed 13 December 2021.

Amazone. Betriebsanleitung, Z. A. T. S. (January 2022). https://et.amazone.de/files/pdf/MG3656.pdf. last accessed 11

Atfarm (2021). Variable rate fertilisation. https://www.at.farm/variable-rate-fertilisation/. last accessed 13 December 2021.

Balafoutis, A., Beck, B., Fountas, S., Vangeyte, J., Wal, T., Soto, I., et al. (2017). Precision agriculture technologies positively contributing to GHG emissions mitigation, farm productivity and economics. Sustainability, 9, 1339. https://doi.org/10.3390/su9081339.

Bayerische Landesanstalt für Landwirtschaft (2018). Agrarumweltmaßnahmen in Bayern: Analyse der Inanspruchnahme 2007–2017 - „Agri-environmental measures in Bavaria: Analysis of utilisation 2007–2017“.

BMEL. Verordnung über die Anwendung von Düngemitteln, Bodenhilfsstoffen, Kultursubstraten und Pflanzenhilfsmitteln nach den Grundsätzen der guten fachlichen Praxis beim Düngen: Düngeverordnung – DüV - „Ordinance on the application of fertilisers, soil additives, growing media and plant aids in accordance with the principles of good fertiliser practice:Fertiliser Ordinance – DüV. “

BMEL (2020). Verordnung zur Änderung der Düngeverordnung und anderer Vorschriften - „Ordinance amending the Fertiliser Ordinance and other regulations“.

Bogballe (2019). Bogballe Media Portal. https://media.bogballe.com/#!/asset/5315. Accessed 11 January 2022.

Bongiovanni, R., & Lowenberg-Deboer, J. (2004). Precision agriculture and sustainability. Precision Agriculture, 5, 359–387. https://doi.org/10.1023/B:PRAG.0000040806.39604.aa.

Ebertseder, T., Gutser, R., Hege, U., Brandhuber, R., & Schmidhalter, U. (2003). Strategies for site-specific nitrogen fertilization with respect to long-term environmental demands. In Precision Agriculture. In Proceedings of the 4th European Conference on Precision Agriculture, Berlin, Germany, 15–19 June, pp. 193–198.

Ebertseder, T., Schmidhalter, U., Gutser, R., Hege, U., & Jungert, S. (2005). Evaluation of mapping and on-line nitrogen fertilizer application strategies in multi-year and multi-location static field trials for increasing nitrogen use efficiency of cereals. In: Stafford, J. V. (ed.) Proceedings of the 5th European Conference on Precision Agriculture, Wageningen Academic Publisher, The Netherlands, pp. 327–335.

English, B. C., Mahajanashetti, S. B., & Roberts, R. K. (1999). Economic and environmental benefits of variable rate application of nitrogen to corn fields: Role of variability and weather. 1999 Annual Meeting, August 8–11, Nashville, TN(21533).

esa (2022a). Sentinel-2 - Missions - Sentinel Online. https://sentinel.esa.int/web/sentinel/missions/sentinel-2. last accessed 2 May 2022.

esa (2022b). Sentinel-2 - Missions - Sentinel Online. https://sentinel.esa.int/web/sentinel/missions/sentinel-2. last accessed 2 May 2022.

Fulton, J. P., Shearer, S. A., Higgins, S. F., Darr, M. J., & Stombaugh, T. S. (2005). Rate response assessment from various granular VRT applicators. Transactions of the ASAE, 48(6), 2095–2103.

Geesing, D., Diacono, M., & Schmidhalter, U. (2014). Site-specific effects of variable water supply and nitrogen fertilisation on winter wheat. Journal of Plant Nutrition and Soil Science, 177, 509–523. https://doi.org/10.1002/jpln.201300215.

geo-konzept (2021). Fernerkundung_Produktuebersicht_Anwendungen_Landwirtschaft - geo-konzept. https://geo-konzept.de/uebersicht-fernerkundung/anwendungen-landwirtschaft/. last accessed 13 December 2021.

Google (2022). earth engine-API. https://github.com/google/earthengine-api. Last accessed 2 May 2022.

Griepentrog, H. W. (1997). Teilflächenspezifische Düngung. LANDTECHNIK, 52(1), 12–13. https://doi.org/10.15150/lt.1997.2573.

Griepentrog, H. W., & Persson, K. (2001). A model to determine the positional lag for fertilizer spreaders. In Precision Agriculture 2001. Proceedings of the 3rd European conference on precision agriculture, eds. S. Blackmore and G. Grenier, Agro Montpellier, pp. 671–676.

Griepentrog, H. W., Thiessen, E., Kristensen, H., & Knudsen, L. (2007). A patch-size index to assess machinery to match soil and crop spatial variability. Precision Agriculture, ‘07, 407–413.

Guerrero, A., & Mouazen, A. M. (2021). Evaluation of variable rate nitrogen fertilization scenarios in cereal crops from economic, environmental and technical perspective. Soil and Tillage Research, 213, 105110. https://doi.org/10.1016/j.still.2021.105110.

Hofste, R. (2018). eeconvert. https://github.com/gee-community/eeconvert. last accessed 2 May 2022.

Hu, Y., & Schmidhalter, U. (2021). Urease inhibitors: opportunities for meeting EU national obligations to reduce ammonia emission ceilings by 2030 in EU countries. Environmental Research Letters, 16, 8. https://doi.org/10.1088/1748-9326/ac16fe.

Hunter, J. D. (2007). Matplotlib: a 2D graphics environment. Computing in Science & Engineering, 9, 90–95. https://doi.org/10.1109/MCSE.2007.55.

Jin, Z., Archontoulis, S. V., & Lobell, D. B. (2019). How much will precision nitrogen management pay off? An evaluation based on simulating thousands of corn fields over the US Corn Belt. Field Crops Research, 240, 12–22.

Jordahl, K. (2014). GeoPandas: Python tools for geographic data. URL: https://github.com/geopandas/geopandas.

KleffmanDigital (2021). Applikationskarten / MyDataPlant. https://mydataplant.com/de/application-maps.html. last accessed 13 December 2021.

Leroux, C., Jones, H., Clenet, A., & Tisseyre, B. (2017). A new approach for zoning irregularly-spaced, within-field data. Computers and Electronics in Agriculture, 141, 196–206. https://doi.org/10.1016/j.compag.2017.07.025.

McKinney, W. (2010). Data structures for statistical computing in python. Proceedings of the 9th python in science conference, – 58–61.

Mittermayer, M., Gilg, A., Maidl, F. X., Nätscher, L., & Hülsbergen, K. J. (2021). Site-specific nitrogen balances based on spatially variable soil and plant properties. Precision Agriculture, 22, 1416–1436. https://doi.org/10.1007/s11119-021-09789-9.

Oliphant, T. E. (2006). A guide to NumPy (1 vol.). Trelgol Publishing USA.

Pedregosa, F., Varoquaux, G., Gramfort, A., Michel, V., Thirion, B., Grisel, O., et al. (2011). Scikit-learn: machine learning in Python. Journal of Machine Learning Research, 12, 2825–2830.

Project Jupyter (2022). Jupyter Notebook. https://jupyter.org/. last accessed 2 May 2022.

Python Software Foundation (2022). Python. https://www.python.org/. last accessed 2 May 2022.

RAUCH Landmaschinenfabrik GmbH. AXIS-M 50.2 Mineral fertiliser spreader. https://rauch.de/fileadmin/downloads/betriebsanleitungen/AXIS-M_50_2/5902381-a-de-1217.pdf. Last accessed 11 January 2022.

Raun, W. R., Solie, J. B., Johnson, G. V., Stone, M. L., Mullen, R. W., Freeman, K. W., et al. (2002). Improving nitrogen use efficiency in cereal grain production with optical sensing and variable rate application. Agronomy Journal, 94, 815. https://doi.org/10.2134/agronj2002.0815.

Roudier, P., Tisseyre, B., Poilvé, H., & Roger, J. M. (2011). A technical opportunity index adapted to zone-specific management. Precision Agriculture, 12, 130–145. https://doi.org/10.1007/s11119-010-9160-y.

Rouse, J., Haas, R., Schell, J., Deering, D., Harlan, J. (1974): Monitoring the vernal advancements and retrogradation of natural vegetation. NASA/GSFC, Final Report, Greenbelt, MD, USA, 1–137.

Runge, M., Fulton, J., Griffin, T., Virk, S., & Brooke, A. (2014). Automatic section control technology for row crop planters. Alabama extension.

Schmidhalter, U., Maidl, F. X., Heuwinkel, H., Demmel, M., Auernhammer, H., Noack, P. O. (2008). Chapter 2.3 - Precision farming – adaptation of land use management to small scale heterogeneity. In P. Schröder, J. Pfadenhauer, & J. C. Munch (Eds.), Perspectives for Agroecosystem Management (pp. 121–199). San Diego: Elsevier.

Schuster, J., Mittermayer, M., Maidl, F. X., Nätscher, L., & Hülsbergen, K. J. (2022). Spatial variability of soil properties, nitrogen balance and nitrate leaching using digital methods on heterogeneous arable fields in southern Germany. Precision Agriculture. https://doi.org/10.1007/s11119-022-09967-3.

Sean Gillies (2007-). Shapely: manipulation and analysis of geometric objects. https://github.com/Toblerity/Shapely.

Sharipov, G., Heiß, A., Eshkabilov, S., Griepentrog, H., & Paraforos, D. (2021). Variable rate application accuracy of a centrifugal disc spreader using ISO 11783 communication data and granule motion modeling. Computers and Electronics in Agriculture, 182, 106006.

Shockley, J., Dillon, C. R., Stombaugh, T., & Shearer, S. (2012). Whole farm analysis of automatic section control for agricultural machinery. Precision Agriculture, 13, 411–420. https://doi.org/10.1007/s11119-011-9256-z.

Solorrow (2021). Applikationskarte — Solorrow. https://www.solorrow.com/applikationskarte. last accessed 13 December 2021.

Sozzi, M., Kayad, A., Gobbo, S., Cogato, A., Sartori, L., & Marinello, F. (2021). Economic comparison of satellite, plane and UAV-acquired NDVI images for site-specific nitrogen application: observations from Italy. Agronomy Journal, 11(11), 2098. https://doi.org/10.3390/agronomy11112098.

Stamatiadis, S., Schepers, J. S., Evangelou, E., Tsadilas, C., Glampedakis, A., Glampedakis, M., et al. (2017). Variable-rate nitrogen fertilization of winter wheat under high spatial resolution. Precision Agriculture, 19, 5. https://doi.org/10.1007/s11119-017-9540-7.

Tisseyre, B., & McBratney, A. B. (2008). A technical opportunity index based on mathematical morphology for site-specific management: an application to viticulture. Precision Agriculture, 9, 101–113. https://doi.org/10.1007/s11119-008-9053-5.

VISTA (2019). Düngung smart! - talkingfields - Betrieblicher Einsatz von Satellitendaten im Pflanzenbau. https://www.talkingfields.de/alle-produkte/duengung-smart/. last accessed 13 December 2021.

Vizzari, M., Santaga, F., & Benincasa, P. (2019). Sentinel 2-based nitrogen VRT fertilization in wheat: comparison between traditional and simple precision practices. Agronomy, 9(6), 278. https://doi.org/10.3390/agronomy9060278.

Wang, Z.-H., & Li, S.-X. (2019). Chapter Three - Nitrate N loss by leaching and surface runoff in agricultural land: A global issue (a review). In D. L. Sparks (Ed.), Advances in Agronomy (Vol. 156, pp. 159–217). Academic Press.

Yara Deutschland (2018). : Yara N-Sensor | Precision Farming | Teilflächenspezifisch Düngen | Yara Deutschland, Available online: https://www.yara.de/pflanzenernaehrung/tools-und-services/n-sensor/. (accessed on 21.11.2022).

Zandonadi, R. S., Luck, J. D., Stombaugh, T. S., Sama, M. P., & Shearer, S. A. (2011). A computational tool for estimating off-target application areas in agricultural fields. Transactions of the ASABE, 54, 41–49. https://doi.org/10.13031/2013.36251.

Acknowledgements

This work was supported as part of the GreenWindows4_0 project by funds of the Federal Ministry of Food and Agriculture 516 (BMEL) based on a decision of the Parliament of the Federal Republic of Germany via the 517 Federal Office for Agriculture and Food (BLE) under the innovation support program.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lösch, M., Schmidhalter, U. Improving the congruency of satellite-based fertilizer maps with field-operable units using pneumatic spreaders. Precision Agric 24, 1312–1332 (2023). https://doi.org/10.1007/s11119-023-09991-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11119-023-09991-x