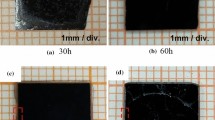

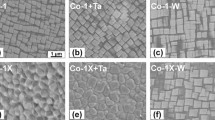

The phase composition, phase growth kinetics, and structures of diffusion zones formed under microwave heating (24 GHz) (MWH) and conventional heating (CH) in two-layer Al2O3–Y2O3 samples are studied by optical and scanning electron microscopy and electron microprobe analysis. Diffusion annealing was conducted at 1700°C for 5 h in vacuum, the heating rate being 10°C/min in all experiments. The diffusion couples included alumina layers, such as coarse-grained polycore or sintered Al2O3–5 vol.% ZrO2 layers, and yttria layers, such as sintered coarse-grained samples or fine Y2O3 powder layers on the Al2O3 surface. It is shown that the phases formed during reactive diffusion do not uniquely correspond to the phase diagram, but depend on the initial structure of contacting layers and the type of heating. This is attributed to the contribution of kinetic factors to the competitive phase growth, particularly to the structural sensitiveness of diffusion coefficients whereby the diffusive phases grow and the stresses appearing when new phases form. It is found that MWH influences the competitive phase growth in the Al2O3–Y2O3 system, which involves both the change in the phase composition of the diffusion zone compared to that formed under CH and the acceleration of phase growth. The maximum effect of the phase growth acceleration under MWH is observed for the YAG phase, which is 30 times as fast as that under CH. It is suggested that the structure of grain boundaries changes and, accordingly, their permeability increases under MWH. The accelerated GB diffusion under MWH promotes the YAG phase growth in both oxides as a result of opposite diffusion flows of Al and Y ions along GBs. Under TH the YAG phase is formed only in Y2O3 oxide because of the unipolar diffusion of Al3+ ions to Y2O3. The validity of the proposed mechanism is confirmed by numerical evaluations.

Similar content being viewed by others

References

Y. J. Su, R. W. Trice, K. T. Faber, et al., “Thermal conductivity, phase stability and oxygen resistance of Y3Al5O12 (YAG)/ Y2O3–ZrO2 thermal-barrier coatings,” Oxid. Met., No. 3–4, 253–271 (2004).

R. S. Roth, Phase Equilibria Diagrams: Phase Diagrams for Ceramics, The American Ceramic Society, Westville, Ohio (1995), Vol. XI, p. 107.

V. B. Glushkova, V. A. Krzhyzhanovskaya, O. N. Egorova, et al., “Interaction of yttrium and aluminum oxides,” Izv. AN SSSR. Neorg. Mater., 19, No. 1, 95–99 (1983).

M. Le Gall, B. Lesage, and J. Bernardini, “Self-diffusion in α-Al2O3. I. Aluminum diffusion in single crystals,” Philos. Mag. A, 70, No. 5, 761–773 (1994).

R. J. Gaboriaud, “Self-diffusion of yttrium in monocrystalline yttrium oxide: Y2O3,” J. Solid State Chem., 35, No. 2, 252–261 (1980).

E. G. Moya, F. Moya, B. Lesage, et al., “Yttrium diffusion in α-alumina single crystal,” J. Europ. Ceram. Soc., 18, 591–594 (1998).

Yu. V. Bykov, O. I. Get’man, S. V. Egorov, et al., “Effect of microwave field on Y3Al5O12 synthesis,” in: Proc. 7th Int. Conf. Materials and Coatings in Extreme Conditions [in Russian], Inst. Probl. Materialoved. NAN Ukrainy, Kiev (2012), p. 186.

K. I. Rybakov and V. E. Semenov, “Mass transport in ionic crystals induced by the ponderomotive action of a high-frequency electric field,” Phys. Rev. B, 52, No. 5, 3030–3033 (1995).

Yu. Bykov, A. Eremeev, M. Glyavin, et al., “24-84-GHz gyrotron systems for technological microwave applications,” IEEE Trans. Plasma Sci., 32, No. 1, 67–72 (2004).

SIAMS600, SIAMS Ltd., Ekaterinburg, http://siams.com.

O. I. Get’man, V. V. Panichkina, L. N. Paritskaya, et al., “Interdiffusion and structural changes in the Cr2O2–Al2O3(ZrO2) diffusion couple under microwave heating,” Powder Metall. Met. Ceram., 51, No. 11–12, 666–676 (2012).

L. N. Paritskaya, Yu. S. Kaganovskii, V. V. Bogdanov, and W. Lojkowski, “Intermetallic growth under high hydrostatic pressure,” Defect Diff. Forum, 208–209, 151–160 (2002).

Ken Suzuki, Satoru Kano, Masanori Kajihara, et al., “Reactive diffusion between Ag and Sn at solid state temperatures,” Mat. Trans., 46, No. 5, 969–973 (2005).

Acknowledgments

The study has been partially funded under Joint Project of the Ukrainian and Russian Fundamental Research Funds, No. A40.2/033, 2011.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 53, No. 1–2 (495), pp. 12–25, 2014.

Rights and permissions

About this article

Cite this article

Get’man, O.I., Panichkina, V.V., Paritskaya, L.N. et al. Effect of Microwave Heating on the Mass Transfer, Phase Formation, and Microstructural Transformations in the Y2O3–Al2O3 Diffusion Couple. Powder Metall Met Ceram 53, 8–18 (2014). https://doi.org/10.1007/s11106-014-9582-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-014-9582-6