Abstract

Purpose

Binary water - ethanol mixtures, by mimicking a clinically relevant medium’s polarity-driven extraction strength, facilitate experimental modeling of patient exposure to chemicals which can potentially leach from a plastic material for pharmaceutical applications. Estimates of patient exposure could consequently benefit from a quantitative concept for tailoring the extraction strength of the simulating solvent mixture towards the one of the clinically relevant medium.

Methods

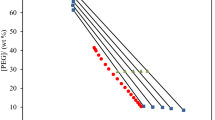

The hypothetical partition coefficient based upon the differential solubility between water-ethanol mixtures and water, \(\log\ \left({\mathrm{S}}_{\mathrm{i},{\mathrm{f}}_C}/{\mathrm{S}}_{\mathrm{i},\mathrm{W}}\right)\), has been calculated by the log-linear model from Yalkowsky and coworkers and a cosolvency model based on Abraham-type linear solvation energy relationships (LSERs). Then, by applying a thermodynamic cycle using the partition coefficient LDPE/water, \(\log \mathrm{K}_{{\mathrm{i}},\mathrm{LDPE/M}}\), partitioning between LDPE and the ethanol in water mixture was calculated and experimentally verified for a wide array of chemically diverse solutes.

Results

The partition coefficients between LDPE and volume fractions of 0.1, 0.2, 0.35 and 0.5 of ethanol in water calculated by this approach correlated well with experimentally obtained values. The LSER based model was found slightly superior over the log-linear cosolvency model.

Conclusions

Solubilization strength projection by means of cosolvency models in combination with LSER predicted partition coefficients LDPE/water enable the tailored preparation of water-ethanol simulating solvent mixtures when input parameters from the clinically relevant medium are available. This approach can increase the reliability of patient exposure estimations and avoid overly complex extraction profiles, thus minimizing time and resources for chemical safety risk assessments on plastic materials used in pharmaceutical applications.

Graphical Abstract

Similar content being viewed by others

Abbreviations

- C:

-

Concentration (molar, volume-based units)

- E, S, A, B, V, L:

-

Abraham-type LSER solute descriptors (-)

- e, s, a, b, v:

-

Abraham-type LSER system parameters (-)

- f:

-

Fraction (0 - 1)

- K:

-

Molar partition coefficient (L/L)

- S:

-

Solubility limit (molar, volume-based units)

- \(\sigma\) :

-

solubilization power of cosolvent (L/L)

- C:

-

Cosolvent

- EtOH:

-

Ethanol

- f:

-

Fraction

- fC = 0 − 1 :

-

Cosolvent fraction, Range 0 (purely aqueous) to 1 (pure cosolvent)

- fEtOH = 0 − 1 :

-

Ethanol fraction, Range 0 (purely aqueous) to 1 (pure ethanol)

- LDPE:

-

Low density polyethylene

- M:

-

Contacting Medium (CM)

- O:

-

Octanol phase

- P:

-

Polymer phase

- W:

-

Water (or aqueous) phase

- eq:

-

At equilibrium

- eff:

-

Effective

References

U.S. Food and Drug Administration (FDA). Guidance for industry: container closure Systems for Packaging Human Drugs and Biologics (chemistry, Manufacturing, and Controls Documentation) 1999.

European medicines agency (EMA). Guideline on Plastic Immediate Packaging Materials 2005.

International Standardization Organisation (ISO). ISO 10993-17:2009 Biological evaluation of medical devices Part 17: Establishment of allowable limits for leachables substances 2012.

International Standardization Organisation (ISO). ISO 10993-18:2020 Biological evaluation of medical devices. Part 18: Chemical characterization of medical device materials within a risk management process. 2020.

Jenke D. Identification, analysis and safety assessment of leachables and extractables. TrAC Trends Anal Chem. 2018;101:56–65. https://doi.org/10.1016/j.trac.2017.10.024.

Jenke D. Compatibility of pharmaceutical products and contact materials: safety considerations associated with Extractables and Leachables: John Wiley and Sons; 2008.

Ball DJ, Norwood DL, Stults CLM, Nagao LM. Safety evaluation, qualification, and best practices applied to inhalation drug products. Hoboken: John Wiley and Sons; 2012.

Jenke D. A general strategy for the chemical aspects of the safety assessment of extractables and leachables in pharmaceutical drug products: the chemical assessment triad. PDA J Pharm Sci Technol. 2012;66(2):168–83. https://doi.org/10.5731/pdajpst.2012.00855.

Paskiet D, Jenke D, Ball D, Houston C, Norwood DL, Markovic I. The product quality research institute (PQRI) leachables and extractables working group initiatives for parenteral and ophthalmic drug product (PODP). PDA J Pharm Sci Technol. 2013;67:430–47.

Brown RP. Allowable limits for toxic leachables: practical use of ISO 10993-17 standard. In: Boutrand J-P, editor. Biocompatibility and performance of medical devices. 2nd ed: Woodhead Publishing, Elsevier Ltd.; 2019. p. 101–18.

Broschard TH, Glowienke S, Bruen US, Nagao LM, Teasdale A, Stults CLM, Li KL, Iciek LA, Erexson G, Martin EA, Ball DJ. Assessing safety of extractables from materials and leachables in pharmaceuticals and biologics – current challenges and approaches. Regul Toxicol Pharmacol. 2016;81:201–11.

Jenke D. Essential aspects in assessing the safety impact of interactions between a drug product and its associated manufacturing system. PDA J Pharm Sci Technol. 2012;66:63–77.

Li K, Rogers G, Nashed-Samuel Y, Lee H, Mire-Sluis A, Cherney B, Forster R, Yeh P, Markovic I. Creating a holistic Extractables and Leachables (E&L) program for biotechnology products. PDA J Pharm Sci Technol. 2015;69:590–619.

Albert DE. A practical approach to analytical chemistry of medical devices. Biocompatibility and Performance of Medical Devices 2019. p. 49–100.

Albert DE. Material and chemical characterization for the biological evaluation of medical device biocompatibility. Biocompatibility and Performance of Medical Devices 2012. p. 65–94.

Jenke D, Egert T, Hendricker A, Castner J, Feinberg T, Houston C, et al. Simulated leaching (migration) study for a model container-closure system applicable to parenteral and ophthalmic drug products. PDA J Pharm Sci Technol. 2017;71(2):68–87. https://doi.org/10.5731/pdajpst.2016.007229.

Jenke D, Odufu A, Poss M. The effect of solvent polarity on the accumulation of leachables from pharmaceutical product containers. Eur J Pharm Sci. 2006;27:133–42.

Yu X, Decou D, Wood D, Zdravkovic S, Schmidt H, Stockmeier L, Piccoli R, Rude D, Ding X. A study of leachables for biopharmaceutical formulations stored in rubber-stoppered glass vials. BioPharm Int. 2010;23:26–36.

Dorey S, Pahl I, Uettwiller I, Priebe P, Hauk A. Theoretical and practical considerations when selecting solvents for use in Extractables studies of polymeric contact materials in single-use systems applied in the production of biopharmaceuticals. Ind Eng Chem Res. 2018;57:7077–89.

United States Pharmacopoeia (USP). <661> Plastic Containers. United States Pharmacopeia (USP) (n.d.).

United States Pharmacopoeia (USP). <1663> Assessment of Extractables associated with Pharmaceutical Packaging/Delivery Systems 2020.

United States Pharmacopoeia (USP). <1664> Assessment of Drug Product Leachables Associated with Pharmaceutical Packaging Delivery Systems. 2020.

United States Pharmacopoeial Forum (PF). Draft <665> Plastic Components and Systems Used to Manufacture Pharmaceutical Drug Products and Biopharmaceutical Drug Substances and Products. PF (45(2). 2020.

United States Pharmacopoeial Forum (PF). <1665> Characterization of plastic materials; components; and systems used in the manufacturing of pharmaceutical drug products and biopharamceutical drug substances and products. United States Pharmacopeial Forum (45(2) March 2019. PF (45(5). 2020.

Biophorum Operations Group (BPOG). Standardized Extractables Testing Protocol for Single Use Systems in Biomanufacturing. 2015.

Product Quality and Research Institute (PQRI). Safety Thresholds and Best Practices for Extractables and Leachables in Orally Inhaled and Nasal Drug Products. 2006.

Feigenbaum AE, Riquet AM, Scholler D. Fatty food simulants: Solvents to mimic the behavior of fats in contact with packaging plastics. ACS Symp Ser. 753 ed2000:71–81.

Baner AL, Franz R, Piringer O. Alternative fatty food simulants for polymer migration testing: experimental confirmation. J Polym Eng. 1996;15(1–2):161–80.

Riquet AM, Feigenbaum A. Food and packaging interactions: tailoring fatty food simulants. Food Addit Contam. 1997;14(1):53–63.

Riquet AM, Bosc V, Feigenbaum A. Tailoring fatty food simulants made from solvent mixtures (1): comparison of methanol, ethanol and isopropanol behaviour with polystrene. Food Addit Contam. 2001;18(2):165–76. https://doi.org/10.1080/02652030010008797.

Reynier A, Dole P, Feigenbaum A. Integrated approach of migration prediction using numerical modelling associated to experimental determination of key parameters. Food Addit Contam. 2002;19:42–55.

Reynier A, Dole P, Feigenbaum A. Migration of additives from polymers into food simulants: numerical solution of a mathematical model taking into account food and polymer interactions. Food Addit Contam. 2002;19:89–102.

Riquet AM, Scholler D, Feigenbaum A. Tailoring fatty food simulants made from solvent mixtures (2): determining the equivalent migration behaviour of olive oil and of solvents in the case of polyolefins. Food Addit Contam. 2002;19(6):582–93. https://doi.org/10.1080/02652030110105194.

Jenke DR, Brennan J, Doty M, Poss M. Use of binary ethanol/water model solutions to mimic the interaction between a plastic material and pharmaceutical formulations. J Appl Polym Sci. 2003;89(4):1049–57.

Jenke D. Experimental Design Considerations for Extractables Simulation Studies (FDA Workshop, Washington DC, November 2016). In: FDA Workshop WD, editor. 2016.

Jenke D, Liu N, Hua Y, Swanson S, Bogseth R. A means of establishing and justifying binary ethanol/water mixtures as simulating solvents in extractables studies. PDA J Pharm Sci Technol. 2015;69(3):1–19. https://doi.org/10.5731/pdajpst.2015.01046.

Zdravkovic S. Comparison of the extraction properties of binary Polysorbate 80/water and isopropanol/water solutions for organic substances originating from a parenteral infusion pump. 2019.

Zdravkovic SA. Comparison of the Solubilization properties of Polysorbate 80 and isopropanol/water solvent Systems for Organic Compounds Extracted from three pharmaceutical packaging configurations. Eur J Pharm Sci. 2016;93:475–83. https://doi.org/10.1016/j.ejps.2016.08.052.

Dorival-García N, Bones J. Evaluation of solvent systems for optimized extractables studies of single use bioprocessing solutions. J Chromatogr A. 2017;1513:69–77. https://doi.org/10.1016/j.chroma.2017.06.066.

Off J Eur Union Commission Regulation (EU) No 10/2011 of 14 January 2011 On plastic materials and articles intended to come into contact with food. 2011.

Guidance for Industry: Preparation of Premarket Submissions for Food Contact Substances: Chemistry Recommendations. U.S. Department of Health and Human Services, Food and Drug Administration, Center for Food Safety and Applied Nutrition. April 2002; 2007.

Snyder LR. Classification of the solvent properties of common liquids. J Chromatogr Sci. 1978;16(6):223–34.

Reichardt C. Solvents and solvent effects: an Introduction. Org Process Res Dev. 2007;11(1):105–13. https://doi.org/10.1021/op0680082.

Reichardt C, Welton T. Solvents and solvent effects in organic chemistry solvents and solvent effects in organic chemistry. 4th ed; 2010.

Schwarzenbach RPG, Philip M, Imboden DM. Chapter 4: background thermodynamics, equilibrium partitioning and acidity constants. Environmental organic chemistry. Hoboken: John Wiley & Sons; 2016.

Banerjee S, Yalkowsky SH. Cosolvent-induced solubilization of hydrophobic compounds into water. Anal Chem. 1988;60(19):2153–5.

Strobel AB, Egert T, Langguth P. Predicting Leachables Solubilization in Polysorbate 80 solutions by a linear solvation energy relationship (LSER). Pharm Res. 2021. https://doi.org/10.1007/s11095-021-03096-8.

Jouyban A. Review of the cosolvency models for predicting solubility of drugs in water-cosolvent mixtures. J Pharm Pharm Sci. 2008;11(1):32–58.

Yalkowsky SH, Roseman TJ. Solubilization of drugs by cosolvents. Drugs Pharm Sci. 1981;12(Tech. Solubilization Drugs):91–134.

Li A, Yalkowsky SH. Solubility of organic solutes in ethanol/water mixtures 115. J Pharm Sci. 1994;83(12):1735–40.

Millard JW, Alvarez-Nunez FA, Yalkowsky SH. Solubilization by cosolvents: establishing useful constants for the log-linear model. Int J Pharm. 2002;245:153–66.

Li A, Yalkowsky SH. Predicting Cosolvency. 1. Solubility ratio and solute log Kow. Ind Eng Chem Res. 1998;37(11):4470–5. https://doi.org/10.1021/IE980232V.

Abraham MH, Acree J. Partition coefficients and solubilities of compounds in the water-ethanol solvent system. J Solut Chem. 2011;40(7):1279–90. https://doi.org/10.1007/s10953-011-9719-x.

Abraham MH, McGowan JC. The use of characteristic volumes to measure cavity terms in reversed phase liquid chromatography. Chromatographia. 1987;23(4):243–6. https://doi.org/10.1007/BF02311772.

Ulrich N, Endo S, Brown TN, Watanabe N, Bronner G, Abraham MH, et al. UFZ-LSER database v 3.2 [Internet], http://www.ufz.de/lserd. 2017.

Egert T. Linear solvation energy relationships (LSERs) for accurate prediction of partition coefficients between low density polyethylene and water - part I: experimental partition coefficients and model calibration. Eur J Pharm Sci. 2022;in submission.

Baner L. Partition coefficients of aroma compounds between polyethylene and aqueous ethanol and their estimation using Unifac and GCFEOS. 1992.

Ozaki A, Gruner A, Störmer A, Brandsch R, Franz R. Correlation between partition coefficients polymer/food simulant, K P,F, and octanol/water, log POW - A new approach in support of migration modeling and compliance testing. Dtsch Lebensm-Rundsch. 2010;106(4):203–8.

Collander R. The partition of organic compounds between higher alcohols and water. Acta Chem Scand. 1951;5:774–80.

Goss KU. Free energy of transfer of a solute and its relation to the partition constant. J Phys Chem B. 2003;107:14025–9.

Seiler A, Bach A, Driffield M, Paseiro Losada P, Mercea P, Tosa V, et al. Correlation of foodstuffs with ethanol-water mixtures with regard to the solubility of migrants from food contact materials. Food Addit Contam Part A Chem Anal Control Exposure Risk Assess. 2014;31(3):498–511. https://doi.org/10.1080/19440049.2014.880518.

Abraham MH, Acree WE Jr. Equations for the Partition of Neutral Molecules, Ions and Ionic Species from Water to Water–Methanol Mixtures. J Solut Chem. 2016:1–14. https://doi.org/10.1007/s10953-016-0479-5.

Abraham MH, Acree WE Jr, Rafols C, Roses M. Equations for the correlation and prediction of partition coefficients of neutral molecules and ionic species in the water–isopropanol solvent system. J Solut Chem. 2021. https://doi.org/10.1007/s10953-021-01063-w.

Acknowledgments and Disclosures

The author would like to acknowledge the support of Boehringer Ingelheim Pharma GmbH. The author reports no competing financial interest.

Funding

This research was funded by Boehringer Ingelheim Pharma GmbH.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

ESM 1

(DOCX 52 kb)

Rights and permissions

About this article

Cite this article

Egert, T., Langowski, HC. Evaluation of Two Cosolvency Models to Predict Solute Partitioning between Polymers (LDPE) and Water - Ethanol Simulating Solvent Mixtures. Pharm Res 39, 733–751 (2022). https://doi.org/10.1007/s11095-022-03210-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-022-03210-4