Abstract

The plasma spray-physical vapor deposition technique (PS-PVD) is used to deposit various types of ceramic coatings. Due to the low operating pressure and high enthalpy transfer to the feedstock, deposition from the vapor phase is very effective. The particular process conditions allow for the deposition of columnar microstructures when applying thermal barrier coatings (TBCs). These coatings show a high strain tolerance similar to those obtained by electron beam-physical vapor deposition (EB-PVD). But compared to EB-PVD, PS-PVD allows significantly reducing process time and costs. The application-related properties of PS-PVD TBCs have been investigated in earlier work, where the high potential of the process was described and where the good resistance to thermo-mechanical loading conditions was reported. But until now, the elementary mechanisms which govern the material deposition have not been fully understood and it is not clear, how the columnar structure is built up. Shadowing effects and diffusion processes are assumed to contribute to the formation of columnar microstructures in classical PVD processing routes. For such structures, crystallographic textures are characteristic. For PS-PVD, however, no crystallographic textures could initially be found using X-ray diffraction. In this work a more detailed TEM investigations and further XRD measurements of the columnar PS-PVD microstructure were performed. The smallest build units of the columnar TBC structure are referred to as sub-columns. The observed semi-single crystal structure of individual sub-columns was analyzed by means of diffraction experiments. The absence of texture in PS-PVD coatings is confirmed and elementary nucleation and growth mechanisms are discussed.

Similar content being viewed by others

References

von Niessen K, Gindrat M, Refke A (2010) Vapor phase deposition using plasma spray PVD. J Therm Spray Technol 19(1–2):502–509

von Niessen K, Gindrat M (2011) Plasma spray PVD: a new thermal spray process to deposit out of the vapor phase. J Therm Spray Technol 20(4):736–743

Hospach A, Mauer G, Vaßen R, Stöver D (2011) Columnar-structured thermal barrier coatings (TBCs) by thin film low-pressure plasma spraying (LPPS-TF). J Therm Spray Technol 20(1–2):116–120

Hospach A, Mauer G, Vaßen R, Stöver D (2012) Characteristics of ceramic coatings made by thin film low pressure plasma spraying (LPPS-TF). J Therm Spray Technol 21:435–440

Hospach A (2012) Untersuchungen zum thin film low pressure plasma spraying (LPPS-TF) Prozess (in German). Ph.D. thesis, Ruhr Universität Bochum, Schriften des Forschungszentrums Jülich, Reihe Energie & Umwelt, Vol. 140

Rezanka S (2015) Abscheidung von Wärmedämmschichtsystemen mit dem Plasma Spray-Physical Vapor Deposition- (PS-PVD-) Prozess – Untersuchung des Prozesses und der hergestellten Schichten (in German). Ph.D. thesis, Ruhr Universität Bochum, Schriften des Forschungszentrums Jülich, Reihe Energie & Umwelt Vol. 290

Vaßen R, Kaßner H, Stuke A, Hauler F, Hathiramani D, Stöver D (2008) Advanced thermal spray technologies for applications in energy systems. Surf Coat Technol 202:4432–4437

Padture NP, Gell M, Jordan EH (2002) Thermal barrier coatings for gas-turbine applications. Science 296:280–284

Cao XQ, Vaßen R, Stöver D (2004) Ceramic materials for thermal barrier coatings. J Eur Ceram Soc 24:1–10

Vaßen R, Stuke A, Stöver D (2009) Recent developments in the field of thermal barrier coatings. J Therm Spray Technol 18:181–186

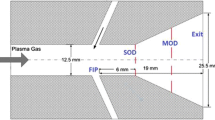

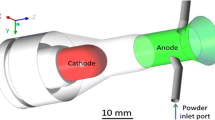

Mauer G (2014) Plasma characteristics and plasma-feedstock interaction under PS-PVD process conditions. Plasma Chem Plasma Proc 34(5):1171–1186

Rezanka S, Mauer G, Vaßen R (2014) Improved thermal cycling durability of thermal barrier coatings manufactured by PS-PVD. J Therm Spray Technol 23:182–189

Marcano D, Mauer G, Sohn YJ, Vaßen R, Garcia-Fayos J, Serra JM (2016) The role of oxygen partial pressure in controlling the phase composition of La1−x Srx Coy Fe1−y O3−δ oxygen transport membranes manufactured by means of plasma spray-physical vapor deposition. J Therm Spray Technol 25:631–638

Marcano D, Mauer G, Sohn YJ, Vaßen R, Garcia-Fayos J, Serra JM (2016) Controlling the stress state of La1−x Srx Coy Fe1−y O3−δ oxygen transport membranes on porous metallic supports deposited by plasma spray-physical vapor process. J Memb Sci 503:1–7

Jarligo MO, Mauer G, Bram M, Baumann S, Vaßen R (2014) Plasma spray physical vapor deposition of La1−x Srx Coy Fe1−y O3−δ thin-film oxygen transport membrane on porous metallic supports. J Therm Spray Technol 23:213–219

Zotov N, Hospach A, Mauer G, Sebold D, Vaßen R (2012) Deposition of La1−x Srx Coy Fe1−y O3−δ coatings with different phase compositions and microstructures by low-pressure plasma spraying-thin film (LPPS-TF) processes. J Therm Spray Technol 21:441–447

Rezanka S, Mack DE, Mauer G, Sebold D, Guillon O, Vaßen R (2017) Investigation of the resistance of open-column-structured PS-PVD TBCs to erosive and high-temperature corrosive attack. Surf Coat Technol 324:222–235

Mauer G, Hospach A, Zotov N, Vaßen R (2013) Process conditions and microstructures of ceramic coatings by gas phase deposition based on plasma spraying. J Therm Spray Technol 22(2–3):83–89

Martin PM (2010) Handbook of deposition technologies for films and coatings, 3rd edn. Elsevier, New York. ISBN 978-0-8155-2031-3

Wada K, Yamaguchi N, Matsubara H (2004) Crystallographic texture evolution in ZrO2–Y2O3 layers produced by electron beam physical vapor deposition. Surf Coat Technol 184:55–62

Singh J, Wolfe DE (2002) Review nano and macro-structured component fabrication by electron beam-physical vapor deposition (EB-PVD). J Mater Sci 37:3261–3267

Schulz U, Schmücker M (2000) Microstructure of ZrO2 thermal barrier coatings applied by EB-PVD. Mat. Sci. Eng. A276:1–8

Mauer G, Rezanka S, Hospach A, Vaßen R, Guillon O (2018) Conditions for nucleation and growth in the substrate boundary layer at plasma spray-physical vapor deposition. Surf Coat Technol

Traeger F, Vaßen R, Rauwald KH, Stöver D (2003) Thermal cycling setup for testing thermal barrier coatings. Adv Eng Mater 5(6):429–432

Yashima M, Sasaki S, Kakihana M, Yamaguchi Y, Arashi H, Yushimura M (1994) Oxygen-induced structural change of the tetragonal phase around the tetragonal-cubic phase boundary in ZrO2-YOl.5 solid solutions. Acta Cryst B50:663–672

Williams DB, Carter CB (2009) Transmission electron microscopy: a textbook for materials science. Springer, New York. ISBN 978-0-387-76501-3

He W, Mauer G, Gindrat M, Wäger R, Vaßen R (2017) Investigations on the nature of ceramic deposits in plasma spray-physical vapor deposition. J Therm Spray Technol 26(1–2):83–92

He W, Mauer G, Vaßen R (2017) Excitation temperature and constituent concentration profiles of the plasma jet under Plasma Spray-PVD conditions. Plasma Chem Plasma Proc 37(5):1293–1311

Acknowledgements

The authors gratefully acknowledge the co-operation with Dr. A. Barth, Dr. H.-M. Höhle and Dr. M. Gindrat, all Oerlikon Metco. CS, GE and RV acknowledge funding through the Collaborative Research Centre SFB/Transregio 103 “From atoms to turbine blades – a scientific basis for a new generation of single crystal superalloys”, Projects A2 and B6, respectively, by the German Research Foundation (DFG).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rezanka, S., Somsen, C., Eggeler, G. et al. A TEM Investigation of Columnar-Structured Thermal Barrier Coatings Deposited by Plasma Spray-Physical Vapor Deposition (PS-PVD). Plasma Chem Plasma Process 38, 791–802 (2018). https://doi.org/10.1007/s11090-018-9898-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-018-9898-y