Abstract

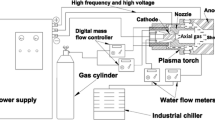

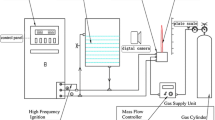

The non-transferred direct current (DC) plasma torch has been widely used in various industrial applications due to its special jet characteristics. The jet characteristics are determined by different factors, including the working parameters, the torch construction, the gas injection angle (GIA) etc. As there is little study on the influence of the GIA on the jet characteristics, experimental study on the GIA’s effects on the jet characteristics has been carried out on a specially designed non-transferred DC plasma torch, whose GIA can be changed by replacing a gas injection component. The arc voltages and thermal efficiencies of the plasma torch, the specific enthalpies and jet lengths of the plasma jets at different working conditions were obtained and analyzed. It has been found that the GIA greatly affects the arc voltage, the thermal efficiency, the specific enthalpy and the jet length. Based on these findings, plasma torch with appropriate GIA could be used to help generating the plasma jet with desired characteristics.

Similar content being viewed by others

References

Mostaghimi J, Boulos MI (2015) Thermal plasma sources: how well are they adopted to process needs? Plasma Chem Plasma Process 35:421–436

Fauchais P, Vardelle M, Goutier S, Vardelle A (2015) Key challenges and opportunities in suspension and solution plasma spraying. Plasma Chem Plasma Process 35:511–525

Fauchais P (2004) Topical review understanding plasma spraying. J Phys D-Appl Phys 37:86–108

Tendero C, Tixier C, Tristant P, Desmaison J, Leprince P (2006) Atmospheric pressure plasmas: a review. Spectrochim Acta Part B 61:2–29

Misra S, Yu L, Chen W, Foldyna M, Cabarrocas PR (2014) A review on plasma-assisted VLS synthesis of silicon nanowires and radial junction solar cells. J Phys D-Appl Phys 47:3001–3021

Solonenko OP, Smirnov AV (2014) Advanced oxide powders processing based on cascade plasma. J Phys Conf Ser 550:1–10

Suresh K, Selvarajan V, Vijay M (2008) Synthesis of nanophase alumina, and spheroidization of alumina particles, and phase transition studies through DC thermal plasma processing. Vacuum 82:814–820

Shigeta M, Murphy AB (2011) Thermal plasmas for nanofabrication. J Phys D Appl Phys 44:4025–4040

Heberlein J, Murphy AB (2008) Thermal plasma waste treatment. J Phys D-Appl Phys 41:3001–3020

Fabry F, Rehmet C, Rohani V, Fulcheri L (2013) Waste gasification by thermal plasma: a review. Waste Biomass Valor 4:421–439

Solonenko OP, Gulyaev IP, Smirnov AV (2011) Thermal plasma processes for production of hollow spherical powders: theory and experiment. J Therm Sci Technol 6:219–234

Cao X, Yu D, Xiao M, Miao J, Xiang Y, Yao J (2016) Design and characteristics of a laminar plasma torch for materials processing. Plasma Chem Plasma Process 36:693–710

Lermen RT, Machado IG (2012) Development of a new hybrid plasma torch for materials processing. J Mater Process Technol 212:2371–2379

Bobzin K, Bagcivan N, Petkovic I (2011) Numerical and experimental determination of plasma temperature during air plasma spraying with a multiple cathodes torch. J Mater Process Technol 211:1620–1628

Pan W, Meng X, Chen X, Wu C (2006) Experimental study on the thermal argon plasma generation and jet length change characteristics at atmospheric pressure. Plasma Chem Plasma Process 26:335–345

Trelles JP, Chazelas C, Vardelle A, Heberlein JVR (2009) Arc plasma torch modeling. J Therm Spray Technol 18:728–752

Miao J, Yu D, Cao X, Xiang Y, Xiao M, Yao J (2015) Experimental study on the characteristics of a miniature laminar plasma torch with different gas flow patterns. Plasma Chem Plasma Process 35:879–893

Osaki K, Fukumasa O, Kobayashi A (2000) High thermal efficiency-type laminar plasma jet generator for plasma processing. Vacuum 59:47–54

Zhou Q, Yin H, Li H, Xu X, Liu F, Guo S, Chang X, Guo W, Xu P (2009) The EFFECT OF PLASMA-GAS SWIRL flOW ON A HIGHLY CONSTRICTED PLASMA CUTTING ARc. J Phys D-Appl Phys 42:5208–5216

Acknowledgments

The authors appreciate the supports of the National Natural Science Foundation of China (No. 51405315).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cao, X., Yu, D., Xiang, Y. et al. Influence of the Gas Injection Angle on the Jet Characteristics of a Non-transferred DC Plasma Torch. Plasma Chem Plasma Process 36, 881–889 (2016). https://doi.org/10.1007/s11090-016-9702-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-016-9702-9