Abstract

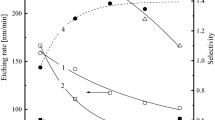

For the purpose of realizing a low-cost production process of silane (SiH4) gas, we have proposed the high-rate etching of metallurgical-grade Si by narrow-gap microwave hydrogen plasma. In this paper, effect of hydrogen gas flow rate (0–10 L/min) on the etch rate has been investigated and correlated with the relative variation of hydrogen-atom density estimated by actinometry. By decreasing hydrogen gas flow rate, the etch rate gradually increases up to the maximum value of 11 μm/min at 2 L/min. This increase is well correlated with the increase of hydrogen-atom density due to the longer residence time of hydrogen molecules in the plasma. On the other hand, when the gas flow rate is lower than 2 L/min, the etch rate abruptly decreases with decreasing gas flow rate in spite of the increase of hydrogen-atom density. From the surface observations and Raman measurements, it is found that the decrease in etch rate in the lower flow rate range is attributed to the formation of microcrystalline Si particles due to the decomposition of generated-SiH4 molecules in the plasma.

Similar content being viewed by others

References

O’Mara WC, Herring RB, Hunt LP (1990) Handbook of semiconductor silicon technology. Noyes, New Jersey

Zulehner W (2000) Mater Sci Eng B 73:7

De Wild-Scholten M, Alsema E (2004) Refocus 5:46

Pizzini S (1982) Sol Energy Mater 6:253

Ma X, Yoshikawa T, Morita K (2012) J Alloys Compd 529:12

Pizzini S (2009) Appl Phys A 96:171

Pires JCS, Braga AFB, Mei PR (2003) Sol Energy Mater Sol Cells 79:347

Hanazawa K, Yuge N, Kato Y (2004) Mater Trans 45:844

Pires JCS, Otubo J, Braga AFB, Mei PR (2005) J Mater Process Technol 169:16

Osokin VA, Shpak PA, Ishchenko VV, Panibratskii VA, Piyuk EL (2008) Metallurgist 52:121

Jiang D, Tan Y, Shi S, Dong W, Gu Z, Guo X (2012) Vacuum 86:1417

Mei PR, Moreira SP, Cardoso E, Côrtes ADS, Marques FC (2012) Sol Energy Mater Sol Cells 98:233

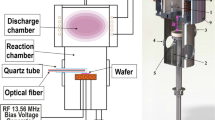

Ohmi H, Kakiuchi H, Hamaoka Y, Yasutake K (2007) J Appl Phys 102:023302

Ohmi H, Goto A, Kamada D, Hamaoka Y, Kakiuchi H, Yasutake K (2009) Appl Phys Lett 95:181506

Yasutake K, Ohmi H, Kakiuchi H (2010) Mater Res Soc Symp Proc 1245:1245-A10-01

Ohmi H, Yamada T, Kakiuchi H, Yasutake K (2011) Jpn J Appl Phys 50:08JD01

Badding JV, Hemley RJ, Mao HK (1991) Science 253:421

Sandrock G, Reilly J, Graetz J, Zhou WM, Johnson J, Wegrzyn J (2005) Appl Phys A 80:687

Borchers C, Khomenko TI, Lenov AV, Morozova OS (2009) Thermochim Acta 493:80

Astashkevich SA, Käning M, Käning E, Kokina NV, Lavrov BP, Ohl A, Röpcke J (1996) J Quant Spectrosc Radiat Transf 56:725

Xiao B, Kado S, Kajita S, Yamasaki D (2004) Plasma Phys Control Fusion 46:653

Yamasaki D, Kado S, Xiao B, Iida Y, Kajita S, Tanaka S (2006) J Phys Soc Jpn 75:044501

Gicquel A, Chenevier M, Hassouni Kh, Tserepi A, Dubus M (1998) J Appl Phys 83:7504

Geng ZC, Xu Y, Yang XF, Wang WG, Zhu AM (2005) Plasma Sources Sci Technol 14:76

Coburn JW, Chen M (1980) J Appl Phys 51:3134

Lavrov BP, Pipa AV (2002) Opt Spectrosc 92:647

Chutjian A, Cartwright DC (1981) Phys Rev A 23:2178

Gicquel A, Derkaoui N, Rond C, Benedic F, Cicala G, Moneger D, Hassouni K (2012) Chem Phys 398:239

Umemoto H, Ohara K, Morita D, Nozaki Y, Masuda A, Matsumura H (2002) J Appl Phys 91:1650

Veprek S, Wang C, Veprek-Heijman MGJ (2008) J Vac Sci Technol A 26(3):313

Izumi A, Sato H, Hashioka S, Kubo M, Matsumura H (2000) Microelectron Eng 51–52:495

Chabert P, Rousseau A, Gousset G, Leprince P (1998) J Appl Phys 84:161

Abrefah J, Olander DR (1989) Surf Sci 209:291

Gates SM, Kunz RR, Greenlief CM (1989) Surf Sci 207:364

Inagaki K, Kanai R, Hirose K, Yasutake K (2011) J Nanosci Nanotechnol 11:2952

Yamada T, Ohmi H, Kakiuchi H, Yasutake K (2012) Jpn J Appl Phys 51:10NA09

Ma Y, Huang YL, Düngen W, Job R, Fahrner WR (2005) Phys Rev B 72:085321

Lengsfeld P, Nickel NH, Fuhs W (2000) J Non Cryst Solids 266–269:659

Acknowledgments

The author thanks Yasushi Oshikane for all his advices in plasma emission measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yamada, T., Ohmi, H., Kakiuchi, H. et al. Effect of H2 Flow Rate on High-Rate Etching of Si by Narrow-Gap Microwave Hydrogen Plasma. Plasma Chem Plasma Process 33, 797–806 (2013). https://doi.org/10.1007/s11090-013-9461-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-013-9461-9