Abstract

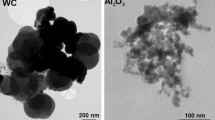

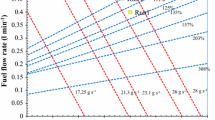

The use of co-electrodeposited nickel-based cermet coatings has been recently considered as a low cost method for protecting the surface of mechanical equipment and machinery against corrosion and high temperature oxidation that are being used in a new oil extraction techniques known as the in situ combustion (ISC) process. In the ISC process, the presence of high temperature atmospheric air can degrade the surface of commercially alloyed components rapidly. This paper investigates the high-temperature oxidation behaviour of novel nanostructured cermet coatings composed of two types of dispersed nanosized ceramic particles (Al2O3 and TiO2) in a nickel matrix and produced by co-electrodeposition technique. For this purpose, high temperature oxidation tests were conducted in dry air for 96 h at 500, 600 and 700 °C to obtain the mass changed per unit of area at specific time intervals. Statistical techniques as described in ASTM G16 were used to formulate the oxidation mass change as a function of time. The cross-section and surface of the oxidized coatings were examined for both visual and chemical analyses using wavelength dispersive X-ray spectroscopy element mapping, X-ray diffraction and energy-dispersive X-ray spectroscopy. The results showed sub-parabolic oxidation behavior up to 600 °C and quasi-liner at temperatures between 600 and 700 °C for the coatings. The spectroscopy results showed formation of two Ni–Ti–O compounds (Ni3TiO5 and NiTiO3) between the dispersed TiO2 and nickel that can ultimately reduce the oxidation rate for the coatings.

Similar content being viewed by others

References

L. M. Castanier and W. E. Brigham, Journal of Petroleum Science and Engineering 39, 125–136 (2003).

Q. Feng, T. Li, H. Teng, X. Zhang, Y. Zhang, Ch Liu and J. Jin, Surface & Coating Technology 202, 4137–4144 (2008).

L. M. Chang, J. H. Liu and R. J. Zhang, Materials and Corrosion, No.999, (Wiley, Weinheim, 2010).

C. Ernest Birchenall, High Temperature Corrosion—NACE-6, (National Association of Corrosion Engineers, Houston, 1982), pp. 3–7.

N. Birks, G. H. Meier and F. S. Pettit, Introduction to the High-Temperature Oxidization, 2nd ed, (Cambridge University Press, Cambridge, 2006).

J. M. West, Basic Corrosion and Oxidation, 1st ed, (Ellis Horwood Ltd., Chichester, 1980).

S. A. Bradford, Fundamental of Corrosion in Gases, Corrosion, vol. 13, (ASM, Materials Park, 2001), pp. 62–76.

J. R. Davis, Heat-Resistant Materials, (ASM International Handbook, Materials Park, 1999), p. 36.

M. A. Wahab, Solid State Physics—Structure and Properties of Materials, Chapter 6, 2nd edn. (Alpha Science International Ltd., Middlesex, 2005).

D. F. Susan and A. R. Marder, Oxidation of Metals 57, 131–158 (2002).

D. F. Susan and A. R. Marder, Oxidation of Metals 57, 159–180 (2002).

R. K. Saha, I. U. Haq, T. I. Khan and L. B. Glenesk, Key Engineering Material 442, 187–194 (2010).

P. Baghery, M. Farzam, A. B. Mousavi and M. Hosseini, Surface & Coatings Technology 204, 3804–3810 (2010).

L. Chen, L. Wang, Zh Zeng and J. Zhang, Material Science and Engineering A 434, 319–325 (2006).

H. Gül, F. Kilic, S. Aslan, A. Alp and H. Akbulut, Wear 267, 976–990 (2009).

C. L. Zeng, M. C. Li, G. Q. Liu and W. T. Wu, Oxidation of Metals 58, 171–184 (2002).

M. A. Farrokhzad and T. I. Khan, Key Engineering Materials 510–511, 32–42 (2012).

M. A. Farrokhzad, G. C. Saha, and T. I. Khan, Surface and Coating Technology. doi:10.1016/j.surfcoat.2013.07.015.

ASTM International, ASTM G16-95, Standard Guide for Applying Statistics to Analysis of Corrosion Data (ASTM International Ltd., West Conshohocken, PA, 2010). doi:10.1520/G0016-95R10.

J. S. Milton and J. C. Arnold, Introduction to Probability and Statistics, 3rd ed, (McGraw-Hill, New York, 1995), pp. 391–398.

D. R. Gabe, Principle of Metal Surface Treatment and Protection, 2nd ed, (Pergamon, Oxford, 1978).

G. Parida, D. Chaira, M. Chopkar and A. Basu, Surface and Coating Technology 205, 4871–4879 (2011).

B. Phillips, et al., Journal of the American Ceramic Society 46, 579–583 (1963).

M. A. Rhamdhani, et al., Metallurgical and Materials Transactions B 40B, 25–37 (2009).

K. P. Trumble and M. Rühle, Acta Metallica Materialia 39, 1915–1924 (1991).

K. P. Lopes, et al., Journal of Alloys and Compounds 468, 327–332 (2009).

A. Qiu et al., Transactions of Nonferrous Metals Society of China, vol. 21. (Nonferrous Metall Society of China Editorial Office, Changsha, 2011), pp. 1808–1816. http://www.elsevier.com/journals/transactions-of-nonferrous-metals-society-of-china/1003-6326.

D. Ortiz de Zarate, et al., New Journal of Chemistry 29, 141–144 (2005).

G. M. Kale, Metallurgical and Materials Transactions B 29B, 31–38 (1998).

W. Laqua and H. Schmalzried, High Temperature Corrosion—NACE-6, (National Association of Corrosion Engineers, Houston, 1982), pp. 110–114.

D. J. Taylor, P. F. Fleig, S. T. Schwab and R. A. Page, Surface and Coating Technology 120–121, 465–469 (1999).

Acknowledgments

The authors would like to thank the department of Mechanical and Manufacturing Engineering University of Calgary, Alberta, Canada and NSERC Canada, and Statoil Canada Ltd. for their financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Farrokhzad, M.A., Khan, T.I. High Temperature Oxidation of Nickel-Based Cermet Coatings Composed of Al2O3 and TiO2 Nanosized Particles. Oxid Met 81, 267–285 (2014). https://doi.org/10.1007/s11085-013-9453-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-013-9453-4