Abstract

This paper proposes a MEMS resonant pressure sensor through implementing an out-of-plane repulsive (levitation) force to enhance the sensor detection threshold and consequently widen its sensing range. 2D and 3D finite-element simulations are conducted and compared to some available experimental data. The simulated results show an increase in the generated levitation force as outstanding merit owing to the added side upper electrodes. The levitation force is then further increased by lateral spacing optimization in association with the assumed applied voltage, which decreases the overall size (footprint) as well. The dynamical behavior around the static equilibrium is first numerically solved using the so-called shooting technique and then compared with an available online simulation tool: the “Matcont” package. The simulated results prove the capability of the online simulator to capture the dynamic response of the resonant micro-sensor when approaching its respective bifurcation points where the stable and unstable branches collide, when in contrary, the shooting technique failed to get the dynamic responses when passing by these bifurcations. Thanks to the fast converging outcomes of the “Matcont” online simulation equipped with simultaneous stability analysis, a comprehensive analysis of the micro-sensor dynamical response is conducted. Three sensing mechanisms as: measurements of frequency shift, amplitude alternation, and amplitude rise/fall near a bifurcation region are evaluated and characterized. Along with enumerating the strengths of the proposed sensor over the conventional capacitive pressure sensors, the advantage of measuring the amplitude rise/fall near the corresponding bifurcation region comparing to the two other sensing mechanisms is detailed, and its possible failure for performance repeatability is resolved by means of the slow-varying frequency sweep. Unlike the traditional parallel-plate configuration in which only one-side frequency shift is observed, in this proposed design, two-sides frequency shift is detected, and accordingly, the reinitialization is categorized based on that. As compared to the conventional MEMS pressure sensor, this revisited design equipped with the suggested sensing mechanism offers wider tunability and sensing range, resolution power enhancement, and simplification of the signal processing circuit.

Similar content being viewed by others

References

Ma, W., Ma, C., Wang, W.: Surface micromachined MEMS deformable mirror based on hexagonal parallel-plate electrostatic actuator. In: Journal of Physics: Conference Series, vol. 986. IOP Publishing, p. 012021 (2018)

Xiang, X., Dai, X., Wang, K., Yang, Z., Sun, Y., Ding, G.: A customized nonlinear micro-flexure for extending the stable travel range of MEMS electrostatic actuator. J. Microelectromech. Syst. 28, 199–208 (2019)

Ouakad, H.M., Younis, M.I.: Modeling the structural–thermal–electrical coupling in an electrostatically actuated MEMS switch and its impact on the switch stability. Math. Probl. Eng. 2013, 1–8 (2013)

Jrad, M., Younis, M.I., Najar, F.: Modeling and design of an electrically actuated resonant microswitch. J. Vib. Control 22(2), 559–569 (2016)

Jia, Y., Yan, J., Soga, K., Seshia, A.A.: Parametric resonance for vibration energy harvesting with design techniques to passively reduce the initiation threshold amplitude. Smart Mater. Struct. 23(6), 065011 (2014)

Madinei, H., Khodaparast, H.H., Adhikari, S., Friswell, M.: Design of MEMS piezoelectric harvesters with electrostatically adjustable resonance frequency. Mech. Syst. Signal Process. 81, 360–374 (2016)

Frangi, A., Guerrieri, A., Carminati, R., Mendicino, G.: Parametric resonance in electrostatically actuated micromirrors. IEEE Trans. Ind. Electron. 64(2), 1544–1551 (2017)

Al-Ghamdi, M., Alneamy, A., Park, S., Li, B., Khater, M., Abdel-Rahman, E., Heppler, G., Yavuz, M.: Nonlinear parameter identification of a resonant electrostatic MEMS actuator. Sensors 17(5), 1121 (2017)

Frangi, A., Laghi, G., Langfelder, G., Minotti, P., Zerbini, S.: Optimization of sensing stators in capacitive MEMS operating at resonance. J. Microelectromech. Syst. 24(4), 1077–1084 (2015)

Finkbeiner, S.: MEMS for automotive and consumer electronics. In: Proceedings of the ESSCIRC (ESSCIRC). IEEE 2013, pp. 9–14 (2013)

Sikarwar, S., Singh, S., Yadav, B.C., et al.: Review on pressure sensors for structural health monitoring. Photonic Sens. 7(4), 294–304 (2017)

Pang, C., Zhao, Z., Zhang, J., Shi, L., Du, L., Fang, Z., Liu, Y.: An advantageous fabrication technology to integrate pressure sensor into multi-sensor for micro weather station. In: 2009 4th IEEE International Conference on Nano/Micro Engineered and Molecular Systems, IEEE, pp. 270–273 (2009)

Yu, Z., Zhao, Y., Sun, L., Tian, B., Jiang, Z.: Incorporation of beams into bossed diaphragm for a high sensitivity and overload micro pressure sensor. Rev. Sci. Instrum. 84(1), 015004 (2013)

Yu, L., Kim, B., Meng, E.: Chronically implanted pressure sensors: challenges and state of the field. Sensors 14(11), 20620–20644 (2014)

Zamanzadeh, M., Rezazadeh, G., Jafarsadeghi-Poornaki, I., Shabani, R.: Static and dynamic stability modeling of a capacitive FGM micro-beam in presence of temperature changes. Appl. Math. Model. 37(10–11), 6964–6978 (2013)

Zhang, W.-M., Yan, H., Peng, Z.-K., Meng, G.: Electrostatic pull-in instability in MEMS/NEMS: a review. Sens. Actuators A 214, 187–218 (2014)

Ghayesh, M.H., Farokhi, H.: Nonlinear behaviour of electrically actuated microplate-based MEMS resonators. Mech. Syst. Signal Process. 109, 220–234 (2018)

Towfighian, S., Seleim, A., Abdel-Rahman, E., Heppler, G.: A large-stroke electrostatic micro-actuator. J. Micromech. Microeng. 21(7), 075023 (2011)

Han, J., Zhang, Q., Wang, W.: Design considerations on large amplitude vibration of a doubly clamped microresonator with two symmetrically located electrodes. Commun. Nonlinear Sci. Numer. Simul. 22(1–3), 492–510 (2015)

Alneamy, A., Al-Ghamdi, M., Park, S., Khater, M., Abdel-Rahman, E., Heppler, G.: Dimpled electrostatic MEMS actuators. J. Appl. Phys. 125(2), 024304 (2019)

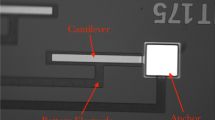

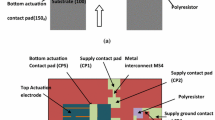

He, S., Mrad, R.B.: Design, modeling, and demonstration of a mems repulsive-force out-of-plane electrostatic micro actuator. J. Microelectromech. Syst. 17(3), 532–547 (2008)

He, S., Mrad, R.B., Chang, J.: Development of a high-performance microelectrostatic repulsive-force rotation actuator. J. Microelectromech. Syst. 19(3), 561–569 (2010)

He, S., Mrad, R.B., Chong, J.: Repulsive-force out-of-plane large stroke translation micro electrostatic actuator. J. Micromech. Microeng. 21(7), 075002 (2011)

Chong, J., He, S., Mrad, R.B.: Development of a vector display system based on a surface-micromachined micromirror. IEEE Trans. Ind. Electron. 59(12), 4863–4870 (2012)

Fan, C., He, S.: A microelectrostatic repulsive-torque rotation actuator with two-width fingers. J. Micromech. Microeng. 25(9), 095006 (2015)

Fan, C., He, S.: A two-row interdigitating-finger repulsive-torque electrostatic actuator and its application to micromirror vector display. J. Microelectromech. Syst. 24(6), 2049–2061 (2015)

He, S., Mrad, R.B.: Large-stroke microelectrostatic actuators for vertical translation of micromirrors used in adaptive optics. IEEE Trans. Ind. Electron. 52(4), 974–983 (2005)

Pallay, M., Daeichin, M., Towfighian, S.: Dynamic behavior of an electrostatic mems resonator with repulsive actuation. Nonlinear Dyn. 89(2), 1525–1538 (2017)

Pallay, M., Towfighian, S.: A parametric electrostatic resonator using repulsive force. Sens. Actuators A 277, 134–141 (2018)

Pallay, M., Towfighian, S.: A reliable MEMS switch using electrostatic levitation. Appl. Phys. Lett. 113(21), 213102 (2018)

Pallay, M., Miles, R.N., Towfighian, S.: Merging parallel-plate and levitation actuators to enable linearity and tunability in electrostatic mems. J. Appl. Phys. 126(1), 014501 (2019)

Pallay, M., Miles, R.N., Towfighian, S.: A tunable electrostatic MEMS pressure switch. IEEE Tran. Ind. Electron. (2019). https://doi.org/10.1109/TIE.2019.2956377

Ren, S., Yuan, W., Qiao, D., Deng, J., Sun, X.: A micromachined pressure sensor with integrated resonator operating at atmospheric pressure. Sensors 13(12), 17006–17024 (2013)

Hasan, M.H., Alsaleem, F.M., Ouakad, H.M.: Novel threshold pressure sensors based on nonlinear dynamics of MEMS resonators. J. Micromech. Microeng. 28(6), 065007 (2018)

Kumar, V., Boley, J.W., Yang, Y., Ekowaluyo, H., Miller, J.K., Chiu, G.T.-C., Rhoads, J.F.: Bifurcation-based mass sensing using piezoelectrically-actuated microcantilevers. Appl. Phys. Lett. 98(15), 153510 (2011)

Kumar, V., Yang, Y., Boley, J.W., Chiu, G.T.-C., Rhoads, J.F.: Modeling, analysis, and experimental validation of a bifurcation-based microsensor. J. Microelectromech. Syst. 21(3), 549–558 (2012)

Rao, S.S., Yap, F.F.: Mechanical Vibrations, vol. 4. Prentice Hall, Upper Saddle River (2011)

Zamanzadeh, M., Ouakad, H.M., Azizi, S.: Theoretical and experimental investigations of the primary and parametric resonances in repulsive force based MEMS actuators. Sens. Actuators A Phys. 303, 111635 (2019)

Younis, M.I., Abdel-Rahman, E.M., Nayfeh, A.: A reduced-order model for electrically actuated microbeam-based MEMS. J. Microelectromech. Syst. 12(5), 672–680 (2003)

Ouakad, H.M.: The response of a micro-electro-mechanical system (MEMS) cantilever-paddle gas sensor to mechanical shock loads. J. Vib. Control 21(14), 2739–2754 (2015)

Ouakad, H.M.: Electrostatic fringing-fields effects on the structural behavior of MEMS shallow arches. Microsyst. Technol. 24(3), 1391–1399 (2018)

Ouakad, H.M.: Static response and natural frequencies of microbeams actuated by out-of-plane electrostatic fringing-fields. Int. J. Non-Linear Mech. 63, 39–48 (2014)

Mohammad, T.F., Ouakad, H.M.: Static, eigenvalue problem and bifurcation analysis of MEMS arches actuated by electrostatic fringing-fields. Microsyst. Technol. 22(1), 193–206 (2016)

De Pasquale, G., Somà, A.: Dynamic identification of electrostatically actuated MEMS in the frequency domain. Mech. Syst. Signal Process. 24(6), 1621–1633 (2010)

Ozdogan, M., Daeichin, M., Ramini, A., Towfighian, S.: Parametric resonance of a repulsive force MEMS electrostatic mirror. Sens. Actuators A 265, 20–31 (2017)

Zamanzadeh, M., Azizi, S.: Static and dynamic characterization of micro-electro-mechanical system repulsive force actuators. J. Vib. Control (2019). https://doi.org/10.1177/1077546319892131

Shampine, L.F., Kierzenka, J., Reichelt, M.W.: Solving boundary value problems for ordinary differential equations in MATLAB with bvp4c. Tutorial notes 2000, pp. 1–27 (2000)

Nayfeh, A.H., Balachandran, B.: Applied Nonlinear Dynamics: Analytical, Computational, and Experimental Methods. Wiley, New York (2008)

Meijer, H.: Matcont tutorial: ODE GUI version (2016)

Younis, M.I.: MEMS Linear and Nonlinear Statics and Dynamics, vol. 20. Springer, Berlin (2011)

Dhooge, A., Govaerts, W., Kuznetsov, Y.A., Mestrom, W., Riet, A., Sautois, B.: MATCONT and CL MATCONT: Continuation Toolboxes in Matlab. Universiteit Gent and Utrecht University, Gent and Utrecht (2006)

Burkardt, J.: The continuation method for algebraic nonlinear equations (2014). https://people.sc.fsu.edu/~jburkardt/presentations/continuation_2014_fsu.pdf

Towfighian, S., He, S., Ben Mrad, R.: A low voltage electrostatic micro actuator for large out-of-plane displacement. In: ASME 2014 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. American Society of Mechanical Engineers Digital Collection (2015)

Nguyen, V.-N., Baguet, S., Lamarque, C.-H., Dufour, R.: Bifurcation-based micro-/nanoelectromechanical mass detection. Nonlinear Dyn. 79(1), 647–662 (2015)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Rights and permissions

About this article

Cite this article

Zamanzadeh, M., Jafarsadeghi-Pournaki, I. & Ouakad, H.M. A resonant pressure MEMS sensor based on levitation force excitation detection. Nonlinear Dyn 100, 1105–1123 (2020). https://doi.org/10.1007/s11071-020-05579-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-020-05579-6