Abstract

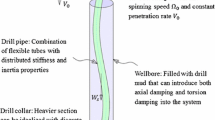

In this article, a discrete model of a drill-string system is developed taking into account stick-slip and time-delay aspects, and this model is used to study the nonlinear motions of this system. The model has eight degrees-of-freedom and allows for axial, torsional, and lateral dynamics of both the drill pipes and the bottom-hole assembly. Nonlinearities that arise due to dry friction, loss of contact, and collisions are considered in the development. State variable dependent time delays associated with axial and lateral cutting actions of the drill bit are introduced in the model. Based on this original model, numerical studies are carried out for different drilling operations. The results show that the motions can be self-exited through stick-slip friction and time-delay effects. Parametric studies are carried out for different ranges of friction and simulations reveal that when the drill pipe undergoes relative sticking motion phases, the drill-bit motion is suppressed by absolute sticking. Furthermore, the sticking phases observed in this work are longer than those reported in previous studies and the whirling state of the drill pipe periodically alternates between the sticking and slipping phases. When the drive speed is used as a control parameter, it is observed that the system exhibits aperiodic dynamics. The system response stability is seen to be largely dependent upon the driving speed. The discretized model presented here along with the related studies on nonlinear motions of the system can serve as a basis for choosing operational parameters in practical drilling operations.

Similar content being viewed by others

References

Navarro-Lopez, E.M., Suarez, R.: Practical approach to modeling and controlling stick-slip oscillations in oilwell drillstrings. In: Proceedings of the 2004 IEEE International Conference on Control Applications, vol. 2, Tapei, Taiwan, September 2004, pp. 1454–1460 (2004)

Liao, C.-M., Balachandran, B., Karkoub, M., Abdel-Magid, Y.L.: Drill-string dynamics: reduced-order models and experimental studies. J. Vib. Acoust. 133(4), 041008 (2011)

Pavone, D.R., Desplans, J.P.: Application of high sampling rate downhole measurements for analysis and cure of stick-slip in drilling. In: SPE Annual Technical Conference and Exhibition, New Orleans, Lousiana, USA, pp. 335–345 (1994). 28324

Brett, J.F.: The genesis of torsional drillstring vibrations. SPE Drill. Eng. 7(3), 168–174 (1992)

Mihajlović, N., van Veggel, A.A., van de Wouw, N., Nijmeijer, H.: Analysis of friction-induced limit cycling in an experimental drill-string system. J. Dyn. Syst. Meas. Control 126(4), 709–720 (2004)

Yigit, A.S., Christoforou, A.P.: Stick-slip and bit-bounce interaction in oil-well drillstrings. J. Energy Resour. Technol. 128(4), 268–274 (2006)

Leine, R.I., van Campen, D.H., Keultjes, W.J.G.: Stick-slip whirl interaction in drillstring dynamics. J. Vib. Acoust. 124(2), 209–220 (2002)

Richard, T., Germay, C., Detournay, E.: Self-excited stick-slip oscillations of drill bits. C. R., Méc. 332(8), 619–626 (2004)

Richard, T., Germay, C., Detournay, E.: A simplified model to explore the root cause of stick-slip vibrations in drilling systems with drag bits. J. Sound Vib. 305(3), 432–456 (2007)

Germay, C., van de Wouw, N., Nijmeijer, H., Sepulchre, R.: Nonlinear drillstring dynamics analysis. SIAM J. Appl. Dyn. Syst. 8(2), 527–553 (2009)

Besselink, B., van de Wouw, N., Nijmeijer, H.: A semi-analytical study of stick-slip oscillations in drilling systems. Journal of Computational and Nonlinear Dynamics 6(2), 021006 (2011)

Brett, J.F., Warren, T.M., Behr, S.M., Amoco Production Co: Bit whirl—a new theory of pdc bit failures. SPE Drill. Eng. 5(4), 275–281 (1990)

Li, Z.: Tubular Mechanics in Oil–Gas Wells and Its Applications, pp. 4–27 (2007). Petroleum Industry Press

Germay, C., Denoėl, V., Detournay, E.: Multiple mode analysis of the self-excited vibrations of rotary drilling systems. J. Sound Vib. 325(1–2), 362–381 (2009)

Kreuzer, E., Struck, H.: Active damping of spatio-temporal dynamics of drill-strings. In: IUTAM Symposium on Chaotic Dynamics and Control of Systems and Processes in Mechanics, vol. 122, pp. 407–417 (2005)

Detournay, E., Defourny, P.: A phenomenological model for the drilling action of drag bits. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 29(1), 13–23 (1992)

Tlusty, J., Ismail, F.: Basic non-linearity in machining chatter. CIRP Ann. 30(1), 299–304 (1981)

Balachandran, B.: Nonlinear dynamics of milling processes. Philos. Trans. R. Soc. Lond. Ser. A, Math. Phys. Sci. 359(1781), 793–819 (2001)

Leine, R.I., van Campen, D.H., de Kraker, A., van den Steen, L.: Stick-slip vibrations induced by alternate friction models. Nonlinear Dyn. 16, 41–54 (1998)

Warren, T.M., Oster, J.H.: Torsional resonance of drill collars with pdc bits in hard rock. In: SPE Annual Technical Conference and Exhibition, New Orleans, Lousiana, USA, pp. 625–637 (1998)

Warren, T.M., Brett, J.F., Allen, S.L., Amoco Production Co: Development of a whirl-resistant bit. SPE Drill. Eng. 5(4), 267–275 (1990)

Wan, M., Zhang, W.H., Dang, J.W., Yang, Y.: A unified stability prediction method for milling process with multiple delays. International Journal of Machine Tools and Manufacture 50(1), 29–41 (2010)

Wan, M., Wang, Y.-T., Zhang, W.-H., Yang, Y., Dang, J.-W.: Prediction of chatter stability for multiple-delay milling system under different cutting force models. International Journal of Machine Tools and Manufacture 51(4), 281–295 (2011)

Long, X.-H., Balachandran, B., Mann, B.: Dynamics of milling processes with variable time delays. Nonlinear Dynamics 47, 49–63 (2007)

Feng, Z.C., Zhang, X.Z.: Rubbing phenomena in rotor-stator contact. Chaos Solitons Fractals 14(2), 257–267 (2002)

Vlajic, N., Liao, C.M., Karki, H., Balachandran, B.: Stick-slip and whirl motions of drill strings: numerical and experimental studies. In: ASME 2011 International Design Engineering Technical Conference & Computers and Information in Engineering Conference, Washington DC, USA, August 2011, p. 47949 (2011)

Arfken, G.B.: Mathematical Methods for Physicists, vol. 1, 2nd edn. pp. 578–579. Academic Press, New York (1970). 1970

Liao, C.M., Vlajic, N., Karki, H., Balachandran, B.: Parametric studies on drill-string motions. Int. J. Mech. Sci. 54(1), 260–268 (2012)

Nayfeh, A.H., Balachandran, B.: Applied Nonlinear Dynamics, pp. 461–557. Wiley, New York (2006)

Logan, D., Mathew, J.: Using the correlation dimension for vibration fault diagnosis of rolling element bearings—I. Basic concepts. Mech. Syst. Signal Process. 10(3), 241–250 (1996)

Acknowledgements

The authors from Shanghai Jiao Tong University gratefully acknowledge the support received through 973 Grant No. 2011CB706803.

Author information

Authors and Affiliations

Corresponding author

Appendix: Model coefficients and development

Appendix: Model coefficients and development

The kinetic energy of the rotating system shown in Fig. 2 can be written as

where m 1 and m 2 are the respective translational disk inertias for Disks 1 and 2, and J 1 and J 2 are the respective rotary disk inertias for Disks 1 and 2. An overdot indicates a derivative with respect to t. Assuming linear elasticity and neglecting the buoyancy force from the drill mud, the potential energy of the rotating structure can be constructed as

where EA, GI 0, and EI x are the associated mechanical properties of the drill-pipe’s cross section and g=9.8 m/s2 is the acceleration due to gravity. Here, a prime denotes a partial derivative with respect to z. Making use of shape functions and boundary conditions for each pipe, the spatial integrations in Eq. (27) are carried out, as detailed later in this appendix. To account for the viscous damping of the drill mud acting on each disk, the Rayleigh’s dissipation function is used and obtained as

where c a , c t , and c b are the viscous damping coefficients associated with axial, bending, and torsional motions, respectively.

The discrete translational inertia mass and rotary inertia used in Eq. (26) take the forms

The corresponding geometry parameters for a cross-section of drill pipe are given in Eq. (27).

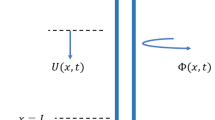

The axial displacement field u(z,t) of the drill pipe used in Eq. (27) is defined as follows

where the coefficients a i , b i (for i=1,2) are functions of time through the displacement variables x 1 and x 2. The boundary conditions are then

On substituting these boundary conditions into Eq. (31), u′ can be obtained as follows:

Following the same procedure as that for the axial motions, the torsional displacement field θ(z,t) of the drill pipe can be defined as

with the associated boundary conditions being

Subsequently, θ′ can be obtained as

The bending displacement field in the x direction can be defined by using polynomials as follows:

Here, the coefficients a i , b i (for i=1,2,3,4) are functions of time through the displacement variables x 1 and x 2. The boundary conditions are of the form

After substituting Eq. (38) into Eq. (37), the different coefficients are obtained and v″ can be determined as

Bending in the y direction is symmetric to that along the x direction, and on this basis, w″ can be written as

After substituting Eqs. (33) to (40) into Eq. (27) and constructing the potential energy, the result is

After making use of Lagrange’s equations

where the Lagrangian L is L=T−V and q i , which are identified as x i ,y i ,z i ,φ i for i=1,2, are the generalized coordinates used to describe the motions of the two disks. The generalized forces \(Q_{q_{i}}\) contain contributions from the centrifugal forces and contact forces as shown in Fig. 2. On substituting Eqs. (26), (28), and (41) into Eq. (42), one obtains the equations of motion as shown in Eq. (1), where the coefficients k i are as follows

Rights and permissions

About this article

Cite this article

Liu, X., Vlajic, N., Long, X. et al. Nonlinear motions of a flexible rotor with a drill bit: stick-slip and delay effects. Nonlinear Dyn 72, 61–77 (2013). https://doi.org/10.1007/s11071-012-0690-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-012-0690-x