Abstract

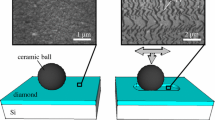

To understand mechanisms of chemical mechanical planarization (CMP), an atomic force microscope (AFM) was used to characterize polished layer surfaces formed by selective transfer after a set of polishing experiments. It is know that in the process of friction of two materials and in the presence of own lubricants, wear phenomenon itself manifests as a transfer of material from an element of a friction couple on the other, this phenomenon being characteristic to the selective transfer process. A selective transfer can be safely achieved in a friction couple, if there is a favorable energy, and in the presence of relative movement, if in the friction area is a material made by copper and the lubricant is adequate (glycerin or special lubricant). The forming selective layer on the contact surfaces makes that the friction force to be very low because of the structure formed by selective transfer. To optimize the CMP process, one needs to obtain information on the interaction between the slurry abrasive particles (with the size range of about 30–70 nm) and the polished surface. To study such interactions, we used AFM. Surface analysis of selective layer using the AFM revealed detailed surface characteristics obtained by CMP. Studying the selective layer CMP, of which the predominated one is copper (in proportion of over 85%), we found that the AFM scanning removes the surface oxide layer in different rates depending on the depth of removal and the pH of the solution. Oxide removal happens considerably faster than the copper CMP removal from the selective layer. This is in agreement with generally accepted models of copper CMP. It was found that removal mechanisms depend on the slurry chemistry, potential per cent of oxidizer, and the applied load. This presentation discusses these findings. Both load force and the friction forces acting between the AFM tip and surface during the polishing process were measured. One big advantage of using the AFM tip (of radius about 50 nm) as abrasive silica particle is that we can measure forces acting between the particle-tip and the surface being polished. Here, we report measurement of the friction force while scratching and polishing. The correlation between those forces and removal rate is discussed.

Similar content being viewed by others

References

Bielmann M, Mahajan U, Singh RK (1999) Enhanced tungsten chemical mechanical polishing using stable alumina slurries. Electrochem Solid-State Lett 2(3):148–150

Du T, Desai V (2003) CMP of copper pH effect. J Mater Sci Lett 22:1623–1625

Du T, Tamboli D, Desai V (2003) Electrochemical characterization of copper. Chemical mechanical polishing. Microelectron Eng 69:1–9

Fisher T, Liang H, Mullins W (1989). New directions in tribology. In: Pope L, Fehrenbacher L, Winer W (eds) Materials Research Society Symposium Proceedings (MRS), Pittsburgh, pp 339–344

Garkunov DN (1981) Erhonung der Verschleissfestigkeit auf der selektiven Ubertragung. VEB Verlag Technik, Berlin

Ilie F (2002) Study tribological of thin superficial layers formed in the friction couples through selective transfer. Technical Publishing House, Bucharest

Ilie F, Tita C (2006) Comparative analysis of tribological performances of materials that can achieve thin layers from selective transfer. J Balk Tribol Assoc 12(4):404–411

Ilie F, Tita C (2011) Selective layer chemical mechanical planarization process mimicked with atomic force microscope. Proc Inst Mech Eng Part J 225(5):289–297

Kaufman FB, Thompson DB, Broadie RE, Jaso MA, Guthrie WL, Pearson DJ, Small MB (1991) A model of chemical mechanical polishing of surfaces coating. J Electrochem Soc 138:3460

Liang H (2005) Chemical boundary lubrification in chemical mechanical planarization. Tribol Int 38:235–242

Liang H, Xu H, Martin J, Mongue Th (2003) Transfer wear during copper CMP. In: Materials Research Society Symposium Proceedings, vol 767. FCMP, San Francisco, pp 111–118

Lu J, Garland J, Petili C, Dobre S, Roy D (2003) Electrochemical studies of copper CMP, mechanism: effects of oxidizer concentration. Mat Res Soc Symp Proc 767:F.6.4.1–6.4.6

Meyer E, Overney RM, Dansfeld K, Gyalog T (1998) Nanoscience: friction and rheology on the nanometer scale. World Scientific, Singapore

Steigerwald DJ, Muraka SP, Gutmann RJ, Duquett D (1995) Chemical processes in the CMP polishing copper. Mater Chem Phys 41:212–228

Steigerwald DJ, Muraka SP, Gutmann RJ (1997) CMP of microelectronics materials. John Wiley, New York

Xu H, Liang H (2002) Effects of electrical potential on CMP of copper. J Electr Mater 31(4):272–277

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ilie, F. Investigation into layers formed by selective transfer CMP mechanisms with atomic force microscope. J Nanopart Res 13, 5519–5526 (2011). https://doi.org/10.1007/s11051-011-0540-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11051-011-0540-7