Special features of the structural and mechanical behavior of aluminum alloy D16 under equal-channel angular pressing (ECAP) and subsequent cooling to cryogenic temperatures are studied. The mean grain size, the conventional yield strength, and the elongation are determined. It is shown that the ECAP refines the grains and raises the strength properties of the alloy.

Similar content being viewed by others

References

V. Yu. Slesarenko, D. A. Gunderov, P. G. Ulyanov, and R. Z. Valiev, “Formation of amorphous states in Ti50Ni25Cu25 alloy subjected to severe plastic deformation: Nanoglass issue, IOP Conf. Series,” Mater. Sci. Eng., 63 (2014).

D. V. Pavlenko, D. V. Tkach, V. Yu. Kotsyuba, and Ya. E. Beigel’zimer, “Analysis of the conditions of formation of submicrocrystalline structure in iron-nickel alloys under helical extrusion,” Metalloved. Term. Obrab. Met., No. 5(743), 8 – 14 (2017).

S. Lezhnev, A. Nayzabekov, A. Volokitin, and I. Volokitina, “New combined process pressing-drawing and impact on properties of deformable aluminum wire,” Proc. Eng., 81, 1505 (2014).

G. Raab, R. Valiev, T. Lowe, and Y. Zhu, “Continuous processing of ultrafine grained Al by ECAP-conform,” Mater. Sci. Eng., 382, 30 – 34 (2004).

I. E. Volokitina, S. N. Lezhnev, E. P. Orlova, and G. G. Kurapov, “Research of the microstructure and mechanical properties of copper and CuZn36 developing during deformation into the equal channel speed matrix with high-intensity cooling,” Key Eng. Mater., 684, 346 (2016).

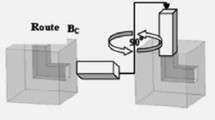

Liu Junway, Ouyang Zipeng, Lu Shiqiang, Jiang Yong, and Huang Yuanzhi, “Effect of ECAP by routes Bc and C on the microstructure and temperature of martensitic transformation of alloy NITINB, Metalloved. Term. Obrab. Met., No. 1(739), 48 – 53 (2017).

A. Naizabekov, S. Lezhnev, and I. Volokitina, “Change in copper microstructure and mechanical properties with deformation in an equal channel stepped die,” Metal Sci. Heat Treat., 57(5 – 6), 254 (2015).

I. Yu. Khmelevskaya, R. D. Karelin, S. D. Prokoshkin, et al., “Effect of quasi-continuous equal channel angular pressing on the structure and functional properties of shape memory Ti – Ni alloys,” Fiz. Met. Metalloved., No. 118(3), 293 (2017).

V. A. Bratov and E. N. Borodin, “Comparison of dislocation density based approaches for prediction of defect structure evolution in aluminum and copper processed by ECAP,” Mater. Sci. Eng. A, 631, 10 – 17 (2015).

I. E. Volokitina and G. G. Kurapov, “Effect of initial structural state on formation of structure and mechanical properties of steel under ECAP,” Metalloved. Term. Obrab. Met., No. 12, 44 – 50 (2017).

K. Venkateswarlu, M. Ghosh, A. K. Ray, et al., “On the feasibility of using a continuous processing technique incorporating a limited strain imposed by ECAP,” Mater. Sci. Eng. A, 485, 476 – 480 (2008).

S. N. Lezhnev, I. E. Volokitina, and T. Koinov, “Document research of influence of equal channel angular pressing on the microstructure of copper,” J. Chem. Technol. Metall., 49(6), 621 (2014).

Yu. M. Vainblat, S. Yu. Klepachevskaya, and P. Sh. Lantsman, “Diagrams of phase states and recrystallization of hot-deformed alloy AK4-1,” Fiz. Met. Metalloved., 44(4), 834 (1977).

Yu. M. Vainblat, “Structural states of semiproducts from deformable aluminum alloys,” Tekhnol. Legk. Splav., No. 8, 34 (1992).

M. A. Vasil’ev, S. M. Voloshko, and L. F. Yatsenko, “Microstructure and mechanical properties of metals and alloys deformed in liquid nitrogen,” Usp. Fiz. Met., 13, 303 – 343 (2012).

S. K. Panigrahi, R. Jayaganthan, V. Pancholi, and M. Gupta, “A DSC study on the precipitation kinetics of cryorolled Al 6063 alloy,” Mater. Chem. Phys., 122, 188 – 193 (2010).

S. Ramesh Kumar, Gudimetla Kondaiah, B. Tejaswi, and B. Ravisankar, “Effect of microstructure and mechanical properties of Al – Mg alloy processed by ECAP at room temperature and cryo temperature,” Trans. Indian Inst. Met., 70, 639 – 648 (2017).

V. L. Niranjani, K. C. H. Kumar, and V. S. Sarma, “Development of high strength Al – Mg – Si AA6061 alloy through cold rolling and aging,” Mater. Sci. Eng. A, 515, 169 – 174 (2009).

A. P. Zhilyaev, A. A. Gimazov, G. L. Raab, and T. G. Langdon, Mater. Sci. Eng. A, 486, 123 (2008).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 4, pp. 31 – 34, April, 2019.

Rights and permissions

About this article

Cite this article

Volokitina, I.E. Effect of Cryogenic Cooling After Ecap on Mechanical Properties of Aluminum Alloy D16. Met Sci Heat Treat 61, 234–238 (2019). https://doi.org/10.1007/s11041-019-00406-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-019-00406-1