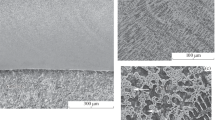

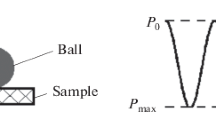

The influence of heat impact at 200 – 1050°C on the structure, phase composition, microhardness and tribological characteristics due to sliding over a NiCrBSi fixed abrasive (corundum) is studied for a PG-10N-01 coating deposited by a gas-powder laser method. A combined laser-and-heat treatment is suggested, which yields a heat-resistant chromium-nickel coating containing a thermally stable high-strength wear-resistant skeleton of coarse carbides and chromium borides.

Similar content being viewed by others

References

Da-Wei Zhang, T. C. Lei, Ji-ge Zhang, and Jia-hu Ouyang, “The effect of heat treatment on microstructure and erosion properties of laser surface-clad Ni-base alloys,” Surf. Coat. Technol., 115, 176 – 183 (1999).

E. Fernandez, M. Cadenas, R. Gonzales, et al., “Wear behavior of laser clad NiCrBSi coating,” Wear, 259, 870 – 875 (2005).

C. Navas, R. Colaco, J. De Damborenea, and R. Vilar, “Abrasive wear behavior of laser clad and flame sprayed-melted NiCrBSi coatings,” Surf. Coat. Technol., 200, 6854 – 6862 (2006).

O. I. Shevchenko, V. M. Farber, V. I. Zhuravlev, et al., “Interrelation of structure, phase composition and surface properties of the working layer of N73Kh16S3R3 rolls formed by plasmapowder surfacing,” Izv. Vysh. Ucheb. Zaved., Chern. Metall., No. 8, 57 – 61 (1995).

Ch. Guoa, J. Zhoua, J. Chena, et al., “High temperature wear resistance of laser cladding NiCrBSi and NiCrBSi/WC-Ni composite coatings,” Wear, 270, 492 – 498 (2011).

A. Zikin, I. Hussainova, C. Katsich, et al., “Advanced chromium-carbide-based hardfacings, Surf. Coat. Technol., 206, 4270 – 4278 (2012).

A. Zikin, M. Antonov, I. Hussainova, et al., “High temperature wear of cermet particle reinforced NiCrBSi hardfacings,” Tribology Int., 68, 45 – 55 (2013).

A. Martin, J. Rodriguez, J. I. Fernández, and R. Vijande, “Sliding wear behavior of plasma sprayed WC-NiCrBSi coatings at different temperatures,” Wear, 251, 1017 – 1022 (2001).

J. Rodriguez, A. Martin, R. Fernández, and J. E. Fernández, “An experimental study of the wear performance of NiCrBSi thermal spray coatings,” Wear, 255, 950 – 955 (2003).

K. Gurumoorthy, M. Kamaraj, K. Prasad Rao, et al., “Microstructural aspects of plasma transferred arc surfaced Ni-based hardfacing alloy,” Mater. Sci. Eng. A, 456, 11 – 19 (2007).

A. G. Grigor’yants and A. N. Safonov, Laser Engineering and Technology, in 7 books. Book 3, Methods of Surface Laser Treatment [in Russian], Vysshaya Shkola, Moscow (1987).

O. I. Shevchenko, V. M. Farber, and G. E. Trekin, “Effect of high-temperature heating on the structure of N73Kh16S3R3 coating formed by plasma-powder surfacing,” Izv. Vysh. Ucheb. Zaved., Chern. Metall., No. 10, 76 – 77 (1994).

H. Skulev, S. Malinov, P. A. M. Basheer, and W. Sha, “Modification of phases, microstructure and hardness of Ni-based alloy plasma coatings due to heat treatment,” Surf. Coat. Technol., 185(1), 18 – 29 (2004).

Quian Ming, L. C. Lim, and Z. D. Chen, “Laser cladding of nickel-based hardfacing alloys,” Surf. Coat. Technol., 106, 174 – 182 (1998).

H. Yan, P. Zhang, Zh. Yu, et al., “Microstructure and tribological properties of laser-clad Ni – Cr/TiB2 composite coatings on copper with the addition of CaF2 ,” Surf. Coat. Technol., 206, 4046 – 4053 (2012).

A. V. Makarov, R. A. Savray, A. L. Osintseva, and I. Yu. Malygina, “Effect of chemical composition on the tribological properties of chromium-nickel coatings formed by gas-powder laser cladding,” Izv. Chelyabinsk Nauch. Tsentra, No. 2(44), 28 – 33 (2009).

A. V. Makarov, E. S. Gorkunov, I. Yu. Malygina, et al., “Eddycurrent control of the hardness, wear resistance and thickness of coatings formed by gas-powder laser cladding,” Defektoskopiya, No. 11, 68 – 78 (2009).

H.-Y. Kim, S.-Y Hwang, C.-H. Lee, and P. Juvanon, “Assessment of wear performance of flame sprayed and fused Ni-based coatings,” Surf. Coat. Technol., 172, 262 – 269 (2003).

S. Lebaili, M. Durand-Charee, and S. Hamar-Thibault, “The metallurgical structure of as-solidified Ni – Cr – B – Si – C hardfacing alloys,” J. Mater. Sci., 23(10), 3603 – 3611 (1988).

N. I. Ganina, A. M. Zakharov, V. G. Olenicheva, and L. A. Petrova, Phase Diagrams of Metallic Systems Published in 1984, Issue XXIX [in Russian], VINITI, Moscow (1986), 524 p.

A. V. Makarov, N. N. Soboleva, I. Yu. Malygina, and A. L. Osintseva, “A method for depositing heat-resistant coating, RF Patent No. 2492980, MPK B23K26/34, B23K26/14,” Byull. Izobr. Polezn. Modeli, No. 26 (2013).

The work has been performed with support of the Program for Fundamental Research of the Ural Branch of the Russian Academy of Sciences, Project No. 12-T-1-1010, within OEMMPU RAN No. 13. The experiments were performed at the Multiple-Access Center “Plastometriya” of the Institute for the Science of Machines of the Ural Branch of the Russian Academy of Sciences.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 3, pp. 39 – 46, March, 2015.

Rights and permissions

About this article

Cite this article

Makarov, A.V., Soboleva, N.N., Malygina, I.Y. et al. Formation of Wear-Resistant Chromium-Nickel Coating with Extra High Thermal Stability by Combined Laser-and-Heat Treatment. Met Sci Heat Treat 57, 161–168 (2015). https://doi.org/10.1007/s11041-015-9856-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-015-9856-8