Abstract

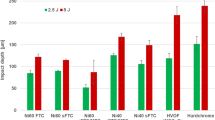

This paper presents the results of our study of the contact endurance of laser-clad chromium–nickel coatings of the NiCrBSi system with different contents of chromium, boron, and carbon (PG-SR2, containing 0.48% C, 14.8% Cr, 2.1% B wt %; and PG-10N-01, containing 0.92% C, 18.2% Cr, 3.3% B wt %) and with additions of carbides of titanium TiC (15 and 25 wt %) and chromium Cr3C2 (15 wt %) upon contact fatigue loading according to the scheme of the pulsing non-impact “sphere-to-surface” contact. It has been established that the contact endurance of chromium–nickel coatings with different chemical compositions and different dispersity of structure is determined by their ability to resist plastic deformation under the conditions of repeated elastic–plastic deformation upon the mechanical non-impact contact action. This study has shown that composite coatings can be created, which contain large (50–150 μm) particles of the strengthening phases, whose contact endurance will not be substantially inferior to the contact endurance of coatings with fine (1–10 μm) strengthening phases. An estimation of the ability of the surface of the coatings to resist the mechanical contact action was made with the use of the data on microindentation. It has been shown that the method of microindentation (single loading) can be used for determining the ability of chromium–nickel coatings to withstand repeated contact loadings.

Similar content being viewed by others

REFERENCES

A. G. Grigor’yants and A. N. Safonov, Laser Techniques and Technology. In 7 books. Book. 3. Methods of Surface Laser Treatment (Vysshaya Shkola, Moscow, 1987) [in Russian].

C. Navas, R. Colaço, J. de Damborenea, and R. Vilar, “Abrasive wear behavior of laser clad and flame sprayed-melted NiCrBSi coatings,” Surf. Coat. Technol. 200, 6854–6862 (2006).

E. Fernández, M. Cadenas, R. González, C. Navas, R. Fernández, and J. de Damborenea, “Wear behaviour of laser clad NiCrBSi coating,” Wear 259, 870–875 (2005).

A. V. Makarov and N. N. Soboleva, “Formation of wear-resistant NiCrBSi coatings by laser surfacing and combined treatments.” in Promising Materials. Vol. VII: A Textbook, Ed. by D. L. Merson (TGU, Tolyatti, 2017) [in Russian], ch. 5, pp. 167–238.

C. Katsich and E. Badisch, “Effect of carbide degradation in a Ni-based hardfacing under abrasive and combined impact/abrasive conditions,” Surf. Coat. Technol. 206, 1062–1068 (2011).

K. Gurumoorthy, M. Kamaraj, K. Rao Prasad, A. Rao Sambasiva, and S. Venugopal, “Microstructural aspects of plasma transferred arc surfaced Ni-based hardfacing alloy,” Mater. Sci. Eng., A 456, 11–19 (2007).

B. Cai, Y.-f. Tan, He L., Tan H., and Gao L., “Tribological properties of TiC particles reinforced Ni-based alloy composite coatings,” Trans. Nonferrous Met. Soc. China 23, 1681–1688 (2013).

A. V. Makarov, N. N. Soboleva, I. Yu. Malygina, and A. L. Osintseva, “Formation of wear-resistant chromium-nickel coating with extra high thermal stability by combined laser-and-heat treatment,” Met. Sci. Heat Treat. 57, 161–168 (2015).

T. Liyanage, G. Fisher, and A. P. Gerlich, “Influence of alloy chemistry on microstructure and properties in NiCrBSi overlay coatings deposited by plasma transferred arc welding (PTAW),” Surf. Coat. Technol. 205, 759–765 (2010).

A. V. Makarov, R. A. Savrai, A. L. Osintseva, and I. Yu. Malygina, “The influence of the chemical composition on the tribological properties of chromium–nickel coatings obtained by the method of gas-powder laser cladding,” Izv. Chelyabinsk NTs UrO RAN, No. 2 (44), 28–33 (2009).

A. V. Makarov, E. S. Gorkunov, I. Yu. Malygina, L. Kh. Kogan, R. A. Savrai, and A. L. Osintseva, “Eddy-current testing of the hardness, wear resistance, and thickness of coatings prepared by gas-powder laser cladding,” Russ. J. Nondestr. Test. 45, 797–805 (2009).

N. N. Soboleva, I. Yu. Malygina, A. L. Osintseva, and N. A. Pozdeeva, “The influence of the microstructure and phase composition on tribological performances of NiCrBSi laser coatings,” Izvestia of RAS SamSC 13, 869–873 (2011).

A. V. Makarov, N. N. Soboleva, and I. Yu. Malygina, “Role of the strengthening phases in abrasive wear resistance of laser-clad NiCrBSi coatings,” J Frict. Wear 38, 272–278 (2017).

A. Zikin, E. Badisch, I. Hussainova, C. Tomastik, and H. Danninger, “Characterisation of TiC–NiMo reinforced Ni-based hardfacing,” Surf. Coat. Technol. 236, 36–44 (2013).

X. H. Wang, M. Zhang, X. M. Liu, S. Y. Qu, and Z. D. Zou, “Microstructure and wear properties of TiC/FeCrBSi surface composite coating prepared by laser cladding,” Surf. Coat. Technol. 202, 3600–3606 (2008).

S. Yang, W. Liu, M. Zhong, and Z. Wang, “TiC reinforced composite coating produced by powder feeding laser cladding,” Mater. Lett. 58, 2958–2962 (2004).

A. V. Makarov, N. N. Soboleva, I. Yu. Malygina, and A. L. Osintseva, “The formation of NiCrBSi–TiC composite coating with increased abrasive wear resistance by gas powder laser cladding,” Uprochn. Tekhnol. Pokr., No. 11 (107), 38–44 (2013).

A. V. Makarov, N. N. Soboleva, I. Yu. Malygina, and A. L. Osintseva, “The tribological performances of a NiCrBSi–TiC laser-clad composite coating under abrasion and sliding friction [Digital resource],” Diagn. Resour. Mech. Mater. Struct., No. 3, 83–97 (2015). http://dream-journal.org/Issues/2015-3/2015-3_33.html.

L. I. Tushinskii, V. A. Bataev, V. M. Potapov, A. A. Bataev, and A. P. Timofeev, “Life of hardened materials under the conditions of contact load,” Met. Sci. Heat Treat. 30, 363–365 (1988).

A. Yonezu, B. Xu, and X. Chen, “An experimental methodology for characterizing fracture of hard thin films under cyclic contact loading,” Thin Solid Films 518, 2082–2089 (2010).

G. Ramírez, A. Mestra, B. Casas, I. Valls, R. Martinez, R. Bueno, A. Goez, A. Mateo, and L. Llanes, “Influence of substrate microstructure on the contact fatigue strength of coated cold-work tool steels,” Surf. Coat. Technol. 206, 3069–3081 (2012).

G. Ramírez, E. Tarrés, B. Casas, I. Valls, R. Martínez, and L. Llanes, “Contact fatigue behavior of PVD-coated steel,” Plasma Processes Polym. 6, S588–S591 (2009).

E. Tarrés, G. Ramírez, Y. Gaillard, E. Jiménez-Piqué, and L. Llanes, “Contact fatigue behavior of PVD-coated hardmetals,” Int. J. Refract. Met. Hard Mater. 27, 323–331 (2009).

I. A. Bataev, A. A. Bataev, M. G. Golkovski, D. S. Krivizhenko, A. A. Losinskaya, and O. G. Leniv-tseva, “Structure of surface layers produced by non-vacuum electron beam boriding,” Appl. Surf. Sci. 284, 472–481 (2013).

R. A. Savrai, A. V. Makarov, N. N. Soboleva, I. Yu. Malygina, and A. L. Osintseva, “The contact endurance of NiCrBSi coatings obtained by gas powder laser cladding,” Obrab. Met., No. 4 (65), 43–51 (2014).

R. A. Savrai, A. V. Makarov, E. S. Gorkunov, L. Kh. Kogan, N. N. Soboleva, I. Yu. Malygina, and A. L. Osintseva, “Eddy-current testing of fatigue degradation under contact loading of NiCrBSi coatings obtained through gas–powder laser cladding,” Russ. J. Nondestr. Test. 51, 692–704 (2015).

R. A. Savrai, A. V. Makarov, N. N. Soboleva, I. Yu. Malygina, and A. L. Osintseva, “The behavior of gas powder laser clad NiCrBSi coatings under contact loading,” J. Mater. Eng. Perform. 25, 1068–1075 (2016).

R. A. Savrai, A. V. Makarov, E. S. Gorkunov, N. N. Soboleva, L. Kh. Kogan, I. Yu. Malygina, A. L. Osintseva, and N. A. Davydova, “Eddy-current testing of the fatigue degradation of a gas powder laser clad NiCrBSi–Cr3C2 composite coating under contact fatigue loading,” AIP Conf. Proc. 1915, No. 040049, 1–4 (2017).

H.-F. Xuan, Q.-Y. Wang, S.-L. Bai, Z.-D. Liu, H.‑G. Sun, and P.-Ch. Yan, “A study on microstructure and flame erosion mechanism of a graded Ni–Cr–B–Si coating prepared by laser cladding,” Surf. Coat. Technol. 244, 203–209 (2014).

Š. Houdková, E. Smazalová, M. Vostřák, and J. Schubert, “Properties of NiCrBSi coating, as sprayed and remelted by different technologies,” Surf. Coat. Technol. 253, 14–26 (2014).

A. V. Makarov, N. A. Pozdejeva, R. A. Savrai, A. S. Yurovskikh, and I. Yu. Malygina, “Improvement of wear resistance of quenched structural steel by nanostructuring frictional treatment,” J. Friction Wear 33, 433–442 (2012).

V. P. Kuznetsov, A. V. Makarov, S. G. Psakhie, R. A. Savrai, I. Yu. Malygina, and N. A. Davydova, “Tribological aspects in nanostructuring burnishing of structural steels,” Phys. Mesomech. 17, 250–264 (2014).

A. V. Makarov, N. N. Soboleva, R. A. Savrai, and I. Yu. Malygina, “Improving the micromechanical properties and wear resistance of nickel-chromium laser clad coating using finishing frictional treatment,” Vektor Nauki TGU, No. 4 (34), 60–67 (2015).

N. B. Pugacheva, E. B. Trushina, and T. M. Bykova, “Research on the tribological properties of iron borides as diffusion coatings,” J. Friction Wear 35, 489–496 (2014).

N. B. Pugacheva, T. M. Bykova, and E. B. Trushina, “The steel-basis structure influence on the diffuzion boride coatings structure and properties,” Uprochn. Tekhnol. Pokr., No. 4 (100), 3–7 (2013).

R. A. Savrai and A. V. Makarov, RF Patent No. 162959, Byull. Izobret., No. 19 (2016).

GOST R 8.748-2011 (ISO 14577-1:2002) State system for ensuring the uniformity of measurements (ICG). Metals and alloys. Measurement of hardness and other characteristics of materials in tool indenting. Part 1. Testing method.

E. V. Kharanzhevskiy, “Separation in liquid and the formation of supersaturated solid solutions in Fe–Cu alloys upon rapid laser melting,” Phys. Met. Metallogr. 117, 889–895 (2016).

L. Llanes, E. Tarrés, G. Ramírez, C. A. Botero, and E. Jiménez-Piqué, “Fatigue susceptibility under contact loading of hardmetals coated with ceramic films,” Procedia Eng. 2, 299–308 (2010).

A. I. Popelyukh, P. A. Popelyukh, A. A. Bataev, A. A. Nikulina, and A. I. Smirnov, “Specific features of the nucleation and growth of fatigue cracks in steel under cyclic dynamic compression,” Phys. Met. Metallogr. 117, 279–287 (2016).

CRC Materials Science and Engineering Handbook, Third Edition, Ed. by W. Alexander and J. F. Shackelford (CRC Press, Boca Raton, 2000).

J. Kováčik, “Correlation between Young’s modulus and porosity in porous materials,” J. Mater. Sci. Lett. 18, 1007–1010 (1999).

Y. T. Cheng and C. M. Cheng, “Relationships between hardness, elastic modulus and the work of indentation,” Appl. Phys. Lett. 73, 614–618 (1998).

S. A. Firstov, V. F. Gorban’, and E. P. Pechkovskii, “Measurement of ultimate values of hardness, elastic strain and stress of materials by an automatic indentation method,” Materialovedenie, No. 8, 15–21 (2008).

T. F. Page and S. V. Hainsworth, “Using nanoindentation techniques for the characterization of coated systems: A critique,” Surf. Coat. Technol. 61, 201–208 (1993).

P. H. Mayrhofer, C. Mitterer, and J. Musil, “Structure–property relationships in single- and dual-phase nanocrystalline hard coatings,” Surf. Coat. Technol. 174–175, 725–731 (2003).

Yu. V. Milman, S. I. Chugunova, and I. V. Goncharova, “Plasticity characteristic obtained by indentation,” Vopr. At. Nauki Tekh., No. 4, 182–187 (2011).

ACKNOWLEDGMENTS

The work was performed within the framework of the state task for the Institute of Engineering Science, Ural Branch, Russian Academy of Sciences, according to the theme no. AAAA-A18-118020790147-4. The scanning electron microscopy and the mechanical and micromechanical tests were performed at the Center of the Collaborative Access “Plastometriya” of the Institute of Engineering Science, Ural Branch, Russian Academy of Sciences. The author is grateful to the Doct. of Eng. Sci. A.V. Makarov for participation in the discussion of results, to Cand. of Eng. Sci. I.Yu. Malygina and to Cand. of Eng. Sci. N.N. Soboleva for their assistance in conducting these studies, and to Cand. of Eng. Sci. A.L. Osintseva for the application of coatings by the method of laser cladding.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by S. Gorin

Rights and permissions

About this article

Cite this article

Savrai, R.A. Resistance of Laser-Clad Chromium–Nickel Coatings to Failure under Contact Fatigue Loading. Phys. Metals Metallogr. 119, 1013–1021 (2018). https://doi.org/10.1134/S0031918X18100113

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X18100113