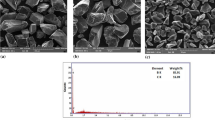

In the present study, an investigation has been carried out into the influence of ZrO2 content and casting temperature on the mechanical properties and fracture behavior of A356 Al/ZrO2 composites. A356 aluminum alloy matrix composites reinforced with 5, 10 and 15 vol.% ZrO2 were fabricated at 750, 850, and 95 0°C via the stir-casting method. Based on the results obtained, the optimum amount of reinforcement and casting temperature were determined by evaluating the density and mechanical properties of the composites through the use of hardness and tensile tests. The fracture surfaces of composite specimens were also studied to identify the main fracture mechanisms of the composites. The results obtained indicated that all samples fractured due to the interdendritic cracking of the matrix alloy. Reinforcing the Al matrix alloy with ZrO2 particles increased the hardness and ultimate tensile strength of the alloy to the maximum values of 70 BHN and 232 MPa, respectively. The best mechanical properties were obtained for the specimens with 15 vol.% of ZrO2 produced at 75 0°C.

Similar content being viewed by others

References

J. P. Davima, J. Silva, and A. M. Baptista, “Experimental cutting model of metal matrix composites (MMCs),” J. Mater. Process. Technol., 183, 358-362 (2007).

M. Kok, “Production and mechanical properties of Al2O3 particle-reinforced 2024 aluminium alloy composites,” J. Mater. Process. Technol., 161, 381–387 (2005).

W. Shyan Lee, W. Chung Sue, and C. Feng Lin, “The effects of temperature and strain rate on the properties of carbon-fiber-reinforced 7075 aluminum alloy metal-matrix composite,” J. Compos. Sci. Technol., 60, 1975-83 (2000).

S. Amirkhanlou, M. R. Rezaei, B. Niroumand, and M. R. Toroghinejad, “Refinement of microstructure and improvement of mechanical properties of Al/Al2O3 cast composite by accumulative roll bonding process,” Mater. Sci. Eng. A, 528, 2548-2553 (2011).

R. Rahmani Fard and F. Akhlaghi, “Effect of extrusion temperature on the microstructure and porosity of A356-SiCp composites,” J. Mater. Process. Technol., 187-188, 433–436 (2007).

J. Hashim, L. Looney, and M. S. J. Hashmi, “Particle distribution in cast metal matrix composites-Part I,” J. Mater. Process. Technol., 123, 251-257 (2002).

R. Jamaati, and M. R. Toroghinejad, “Manufacturing of high-strength aluminum/alumina composite by accumulative roll bonding,” J. Mater. Sci. Eng. A, 527, 4146-4151 (2010).

The American Society for Testing Materials. Standard test method of tension testing wrought and cast aluminum and magnesium alloy products – B557. Handbook of ASTM Standards, Philadelphia—New York (1994).

J. E. Spowart, B. Maruyama, and D. B. Miracle, “Multi-scale characterization of spatially heterogeneous systems: implications for discontinuously reinforced metal–matrix composite microstructures,” J. Mater. Sci. Eng. A, 307, 51-66 (2001).

M. A.Baghchesara, H. Abdizadeh, and H. R. Baharvandi, “Fractography of stir casted Al-ZrO2 composites,” Iran. J. Sci. Technol. Trans. B Eng., 33, 453-462 (2010).

S. Das, S. Das, and K. Das, “Abrasive wear of zircon sand and alumina reinforced Al–4.5 wt.% Cu alloy matrix composites – A comparative study,” J. Comp. Sci. Technol., 67, 746-751 (2007).

W. S. Miller and F. J. Humpherys, “Strengthening mechanisms in particulate metal matrix composites,” J. Scripta Metall. Mater., 25, 33-38 (1991).

V. V. Ganesh and N. Chawla, “Effect of particle orientation anisotropy on the tensile behavior of metal matrix composites:experiments and microstructure-based simulation,” J. Mater. Sci. Eng. A, 391, 342-353 (2005).

Q. Zhang, H. Zhang, M. Gu, and Y. Jin, “Studies on the fracture and flexural strength of Al/Sip composite,” J. Mater. Letters, 58, 3545-3550 (2004).

Y. Li, K. T. Ramesha, and E. S. C. Chin, “Comparison of the plastic deformation and failure of A359/SiC and 6061-T6/Al2O3 metal matrix composites under dynamic tension,” J. Mater. Sci. Eng. A, 371, 359-370 (2004).

B. Y. Lou and J. C. Huang, “Failure characteristics of 6061/ Al2O3/15p and 2014/Al2O3/15p composites as a function of loading rate,” J. Metall. Mater. Trans. A, 27A, 3095-3107 (1996).

J. J. Lewandiwski, C. Liu, and W. H. Hunt, “Effects of matrix microstructure and particle distribution on fracture of an aluminum metal matrix momposite,” J. Mater. Sci. Eng. A, 107, 241-255 (1989).

P. M. Mummery, B. Derby, and C. B. Scruby, “Acoustic emission from particulate-reinforced metal matrix composites,” J. Acta Metall. Mater., 41, 1431-1445 (1993).

Y. Brechet, J. D. Embumy, and L. Luo, “Damage initiation in metal matrix composites,” J. Acta Metall. Mater., 39, 1781-1786 (1991).

R. J. Arsenault, N. Shi, C. R. Feng, and L. Wang, “Localized deformation of SiC-Al composites,” J. Mater. Sci. Eng. A, 131, 55-68 (1991).

J. Llorca, A. Needleman, and S. Suresh, “ An analysis of the effects of matrix void growth on deformation and ductility in metal-ceramic composites,” J. Acta Metall, Mater., 39, 2317-2335 (1991).

S. Tahamtan, A. Fadavi Boostani, “Microstructural characteristics of thixoforged A356 alloy in mushy state,” J. Trans. Nonferrous Met. Soc. China, 20,781–787 (2010).

S. Min, “Effects of volume fraction of SiC particles on mechanical properties of SiC/Al composites,” Trans. Nonferrous met. Soc. China, 19, 1400-1404 (2009).

Author information

Authors and Affiliations

Corresponding author

Additional information

Russian translation published in Mekhanika Kompozitnykh Materialov, Vol. 49, No. 5, pp. 849-858, September-October, 2013.

Rights and permissions

About this article

Cite this article

Abdizadeh, H., Baghchesara, M.A. Investigation into the Mechanical Properties and Fracture Behavior of A356 Aluminum Alloy-Based ZrO2-Particle-Reinforced Metal-Matrix Composites. Mech Compos Mater 49, 571–576 (2013). https://doi.org/10.1007/s11029-013-9373-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11029-013-9373-z