Abstract

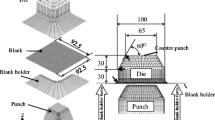

This paper proposes a springback reduction technique with the control of punch speed and blank holder force (BHF) via sequential approximate optimization (SAO). Springback is one of the major defects in sheet forming and its reduction is a crucial issue for improving product quality. Computer-aided-engineering is one of the helpful tools for predicting springback and widely used in automotive industries. Various approaches are considered for springback reduction, and we optimize the punch speed as well as BHF (variable BHF). Sheet forming simulation is generally costly and time-consuming, and the SAO with the radial basis function network is used to determine the optimal punch speed and variable BHF. The U-shaped forming in NUMISHEET’93 is used in the numerical simulation. The standard deviation of the bending moment is minimized subject tearing evaluated with the forming limit diagram. The punch speed and the variable BHF are taken as the design variables. The validity is examined through numerical simulation.

Similar content being viewed by others

References

Bonte, M.H.A., van den Boogaard, A.H., Huetink, J.: An optimization strategy for industrial metal forming processes. Struct. Multidiscip. Optim. 35, 571–586 (2008)

Bonte, M.H.A., Fourment, L., Do, T.T., van den Boogaard, A.H., Huetink, J.: Optimization of forging processes using finite element simulations. Struct. Multidiscip. Optim. 42, 797–810 (2010)

Cao, J., Kinsey, B., Solla, S.A.: Consistent and minimal springback using a stepped binder force trajectory and neural network control. J. Eng. Mater. Technol. 122, 113–118 (2000)

Choi, K.K., Kim, N.H.: Design optimization of springback in a deepdrawing process. AIAA J. 40(1), 147–153 (2002)

Hillmann, M., Kubli, W.: Optimization of sheet metal forming processes using simulation programs. In: NUMISHEET’99, Beasnc, France, 1999, vol. 1, pp. 287–292

Ingaroa, G., Di Lorenzo, R.: Analysis of stamping performances of dual phase steels: a multi-objective approach to reduce springback and thinning failure. Mater. Des. 30, 4421–4433 (2009)

Jakumeit, J., Herdy, M., Nitsche, M.: Parameter Optimization of the sheet metal forming process using an iterative parallel Kriging algorithm. Struct. Multidiscip. Optim. 29, 498–507 (2005)

Jiang, C., Han, X., Liu, G.R., Li, G.Y.: The optimization of the variable binder force in U-shaped forming with uncertain friction coefficient. J. Mater. Process. Technol. 182, 262–267 (2007)

Kitayama, S., Arakawa, M., Yamazaki, K.: Sequential approximate optimization using radial basis function network for engineering optimization. Optim. Eng. 12(4), 535–557 (2011)

Lee, S.W., Yang, D.Y.: An assessment of numerical parameters influencing springback in explicit finite element analysis of sheet metal forming process. J. Mater. Process. Technol. 80–81, 60–67 (1998)

Lepadatu, D., Hambli, R., Kobi, A., Barreau, A.: Optimisation of springback in bending processes using FEM simulation and response surface. Int. J. Adv. Manuf. Technol. 25, 40–47 (2005)

Li, E.: Reduction of springback by intelligent sampling-based LSSVR metamodel-based optimization. Int. J. Mater. Form. 6, 103–114 (2013)

Liu, G., Lin, Z., Xu, W., Bao, Y.: Variable blank holder force in U-shaped part forming for eliminating springback error. J. Mater. Process. Technol. 120, 259–264 (2002)

Nakayama, H., Arakawa, M., Sasaki, R.: Simulation-based optimization using computational intelligence. Optim. Eng. 3, 201–214 (2002)

Papeleux, L., Ponthot, J.P.: Finite element simulation of springback in sheet metal forming. J. Mater. Process. Technol. 125–126, 785–791 (2002)

Song, J.H., Huh, H., Kim, S.H.: Stress-based springback reduction of a channel shaped auto-body part with high-strength steel using response surface methodology. J. Eng. Mater. Technol. 129, 397–406 (2007)

Sunseri, M., Cao, J., Karafillis, A.P., Boyce, M.C.: Accommodation of springback error in channel forming using active binder force control: numerical simulation and experiments. J. Eng. Mater. Technol. 118, 426–435 (1996)

Tozawa, Y.: Theoretical analysis on springback of thin plate. J. Jpn Soc. Mech. Eng. 68(559), 1090–1097 (1965)

Wang, H., Li, E., Li, G.Y.: Optimization of drawbead design in sheet metal forming based on intelligent sampling by using response surface methodology. J. Mater. Process. Technol. 206, 45–55 (2008a)

Wang, H., Li, G.Y., Zhong, Z.H.: Optimization of sheet metal forming processes by adaptive response surface based on intelligent sampling method. J. Mater. Process. Technol. 197, 77–88 (2008b)

Wang, H., Li, E., Li, G.Y.: The least square support vector regression coupled with parallel sampling scheme metamodeling technique and application in sheet forming optimization. Mater. Des. 30, 1468–1479 (2009)

Wang, H., Li, E., Li, G.Y.: Parallel boundary and best neighbor searching sampling algorithm for drawbead design optimization in sheet metal forming. Struct. Multidiscip. Optim. 41, 309–324 (2010)

Wang, H., Li, G., Li, E.: A Comparative study of boundary-based intelligent sampling approaches for nonlinear optimization. Appl. Soft Comput. 11(2), 2227–2238 (2011)

Xu, W.L., Ma, C.H., Li, C.H., Feng, W.J.: Sensitive factors in springback simulation for sheet metal forming. J. Mater. Process. Technol. 151, 217–222 (2004)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kitayama, S., Yoshioka, H. Springback reduction with control of punch speed and blank holder force via sequential approximate optimization with radial basis function network. Int J Mech Mater Des 10, 109–119 (2014). https://doi.org/10.1007/s10999-013-9234-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10999-013-9234-x