Abstract

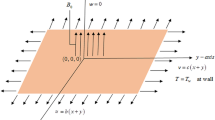

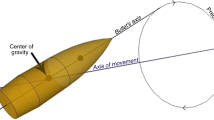

This article aims to study entropy generation and heat transfer due to free convection. Two types of base fluids (water and kerosene oil) are taken with a suspension of titanium alloy nanoparticles. An external magnetic field is applied in a perpendicular direction and the induced magnetic field is neglected. Scientific analysis is performed on magnetohydrodynamic flow through a Darcy medium. Free convection and the sudden motion of the heated plate cause the fluid to flow. The problem is formulated in terms of differential equations with associated physical conditions. Relations for entropy generation and Bejan numbers are also provided. The Laplace transform technique has been used for finding the exact solution to the problem. Results are plotted using Mathcad software and a comparison is made between water-titanium alloy and kerosene oil-titanium alloy nanoparticles for velocity, temperature, entropy generation, and Bejan number. It is concluded that kerosene oil base fluid has a greater velocity and temperature profile in all parametric studies as compared to water-based fluid. While in the case of entropy generation and Bejan number, near to the plate and for away the plate the behaver is distinct. Entropy generation and Bejan number are boosting up via using different base fluid. For larger estimation of Brinkman number, both Bejan number and entropy rate have the opposite effect. The volume fraction of nanofluid enhance the rate of heat transfer in case of both nanofluid. While the water base nanofluid enhance the rate of heat transfer up to 19.14% and kerosene oil base fluid is enhanced up to 30.01%.

Similar content being viewed by others

Abbreviations

- \(\rho\) :

-

Density

- \(\Theta_{\rm w}\) :

-

Wall temperature

- \(u\left( {y_{1} ,t_{1} } \right)\) :

-

Velocity of fluid

- \(U_{0}\) :

-

Constant velocity

- \(\mu\) :

-

Dynamic viscosity

- \(\Omega\) :

-

Dimensionless temperature difference

- \(g\) :

-

Gravitation acceleration

- \(\phi\) :

-

Volume fraction

- \(\beta_{\Theta }\) :

-

Thermal conductivity

- \(N_{\rm H}\) :

-

Entropy generation due to heat transfer

- \(\Theta \left( {y_{1} ,t_{1} } \right)\) :

-

Temperature profile

- \(C_{\rm p}\) :

-

Specific heat capacitance

- \(B_{0}^{2}\) :

-

Magnetic field

- \(N_{\rm F}\) :

-

Entropy generation due to fluid friction

- \(\Theta_{\infty }\) :

-

Imbedded temperature

- \(\sigma\) :

-

Electrical conductivity

- \(\psi\) :

-

Porous medium

- \(Ns\) :

-

Entropy generation

- \(k\) :

-

Permeability of the porous medium

- \(\Pr\) :

-

Prandtl number

- \(\left(\right)_{\rm f}\) :

-

Base fluid

- \(B_{{\text{e}}}\) :

-

Bejan number

- \(\left(\right)_{{\text{s}}}\) :

-

Nanoparticles

- \(K\) :

-

Pours medium permeability

- \(\left(\right)_{{{\text{nf}}}}\) :

-

Nanofluid

- \(Gr\) :

-

Grashof number

- \(M\) :

-

Magnetic parameter

- \(\nu\) :

-

Kinematic viscosity

- \(Br\) :

-

Brinkman number

References

Turkyilmazoglu M. Exact analytical solutions for heat and mass transfer of MHD slip flow in nanofluids. Chem Eng Sci. 2012;84:182–7.

Khalid A, Khan I, Shafie S. Exact solutions for free convection flow of nanofluids with ramped wall temperature. Eur Phys J Plus. 2015;130(4):57.

Ebaid A, Aly EH. Exact analytical solution of the peristaltic nanofluids flow in an asymmetric channel with flexible walls and slip condition: application to the cancer treatment. Comput Math Methods Med. 2013. https://doi.org/10.1155/2013/825376.

Aly EH, Vajravelu K. Exact and numerical solutions of MHD nano boundary-layer flows over stretching surfaces in a porous medium. Appl Math Comput. 2014;232:191–204.

Gohar M, Ali F, Khan I, Sheikh NA, Shah A. The unsteady flow of generalized hybrid nanofluids: applications in cementitious materials. J Aust Ceram Soc. 2019;55(3):657–66.

Ali F, Murtaza S, Khan I, Sheikh NA, Nisar KS. Atangana–Baleanu fractional model for the flow of Jeffrey nanofluid with diffusion-thermo effects: applications in engine oil. Adv Differ Equ. 2019;1:346.

Khan A, Khan D, Khan I, Ali F, ul Karim F, Imran M. MHD flow of sodium alginate-based Casson type nanofluid passing through a porous medium with Newtonian heating. Sci Rep. 2018;8(1):8645.

Saqib M, Ali F, Khan I, Sheikh NA, Shafie SB. Convection in ethylene glycol-based molybdenum disulfide nanofluid. J Therm Anal Calorim. 2019;135(1):523–32.

Wakif A, Boulahia Z, Ali F, Eid MR, Sehaqui R. Numerical analysis of the unsteady natural convection MHD couette nanofluid flow in the presence of thermal radiation using single and two-phase nanofluid models for Cu–Water nanofluids. Int J Appl Comput Math. 2018;4(3):81.

Ali F, Gohar M, Khan I. MHD flow of water-based Brinkman type nanofluid over a vertical plate embedded in a porous medium with variable surface velocity, temperature and concentration. J Mol Liq. 2016;223:412–9.

Atieh AM, Khan TI. Application of Ni and Cu nanoparticles in transient liquid phase (TLP) bonding of Ti-6Al-4V and Mg-AZ31 alloys. J Mater Sci. 2014;49(22):7648–58.

Mohan L, Durgalakshmi D, Geetha M, Narayanan TS, Asokamani R. Electrophoretic deposition of nanocomposite (HAp+ TiO2) on titanium alloy for biomedical applications. Ceram Int. 2012;38(4):3435–43.

Besinis A, Hadi SD, Le HR, Tredwin C, Handy RD. Antibacterial activity and biofilm inhibition by surface modified titanium alloy medical implants following application of silver, titanium dioxide and hydroxyapatite nanocoatings. Nanotoxicology. 2017;11(3):327–38.

Falodun OE, Obadele BA, Oke SR, Olubambi PA, Westraadt J. Characterization of spark plasma sintered TiN nanoparticle strengthened titanium alloy using EBSD and TKD. Mater Res Bull. 2019;117:90–5.

Mechighel F, Armour N, Dost S. Modeling of the effect of the presence of a free surface on transport structures and mixing during the dissolution process of silicon into germanium melt. J Therm Anal Calorim. 2020;2021(146):61–91. https://doi.org/10.1007/s10973-020-09957-5.

Raju CSK, Hoque MM, Anika NN, Mamatha SU, Sharma P. Natural convective heat transfer analysis of MHD unsteady Carreau nanofluid over a cone packed with alloy nanoparticles. Powder Technol. 2017;317:408–16.

Yu W, Xie H. A review on nanofluids: preparation, stability mechanisms, and applications. J Nanomater. 2012;2012:1–17. https://doi.org/10.1155/2012/435873.

Alkanhal TA, Sheikholeslami M, Arabkoohsar A, Haq RU, Shafee A, Li Z, Tlili I. Simulation of convection heat transfer of magnetic nanoparticles including entropy generation using CVFEM. Int J Heat Mass Transf. 2019;136:146–56. https://doi.org/10.1016/j.ijheatmasstransfer.2019.02.095.

Shah Z, Kumam P, Selim MM, Alshehri A. Impact of nanoparticles shape and radiation on the behavior of nanofluid under the Lorentz forces. Case Stud Therm Eng. 2021;26:101161.

Shah Z, Alzahrani EO, Alghamdi W, Ullah MZ. Influences of electrical MHD and Hall current on squeezing nanofluid flow inside rotating porous plates with viscous and joule dissipation effects. J Therm Anal Calorim. 2020;140(3):1215–27.

Shah Z, Dawar A, Islam S. Influence of Brownian motion and thermophoresis parameters on silver-based di-hydrogen CNTs between two stretchable rotating disks. Phys Scr. 2021;96(5):055205.

Babazadeh H, Shah Z, Ullah I, Kumam P, Shafee A. Analysis of hybrid nanofluid behavior within a porous cavity including Lorentz forces and radiation impacts. J Therm Anal Calorim. 2021;143(2):1129–37.

Khan U, Zaib A, Khan I, Nisar KS. Activation energy on MHD flow of titanium alloy (Ti6Al4V) nanoparticle along with a cross flow and streamwise direction with binary chemical reaction and non-linear radiation: dual solutions. J Market Res. 2019;9(1):188–99. https://doi.org/10.1016/j.jmrt.2019.10.044.

Sooppy Nisar K, Khan D, Khan A, Khan WA, Khan I, Aldawsari AM. Entropy generation and heat transfer in drilling nanoliquids with clay nanoparticles. Entropy. 2019;21(12):1226. https://doi.org/10.3390/e21121226.

Bejan A. Second-law analysis in heat transfer and thermal design. Adv Heat Transf. 1982;15:1–58. https://doi.org/10.1016/S0065-2717(08)70172-2.

Bejan A. Entropy generation minimization. Boca Raton: CRC Press; 1996.

Bejan A. A study of entropy generation in fundamental convective heat transfer. J Heat Transf. 1979;101:718–25. https://doi.org/10.1115/1.3451063.

Bejan A. The thermodynamic design of heat and mass transfer processes and devices. Int J Heat Fluid Flow. 1987;8:259–76. https://doi.org/10.1016/0142-727X(87)90062-2.

Hosseini SR, Sheikholeslami M. Investigation of the nanofluid convective flow and entropy generation within a microchannel heat sink involving magnetic field. Powder Technol. 2019;351:195–202. https://doi.org/10.1016/j.powtec.2019.04.022.

Abbasi FM, Shanakhat I, Shehzad SA. Entropy generation analysis for peristalsis of nanofluid with temperature dependent viscosity and Hall effects. J Magn Magn Mater. 2019;474:434–41. https://doi.org/10.1016/j.jmmm.2018.10.132.

Ellahi R, Sait SM, Shehzad N, Mobin N. Numerical simulation and mathematical modeling of electro-osmotic Couette–Poiseuille flow of MHD power–law nanofluid with entropy generation. Symmetry. 2019;11(8):1–25. https://doi.org/10.3390/sym11081038.

Shashikumar NS, Gireesha BJ, Mahanthesh B, Prasannakumara BC, Chamkha AJ. Entropy generation analysis of magneto-nanoliquids embedded with aluminium and titanium alloy nanoparticles in microchannel with partial slips and convective conditions. Int J Numer Methods Heat Fluid Flow. 2018;29(10):3638–58. https://doi.org/10.1108/HFF-06-2018-0301.

Zaib A, Khan U, Khan I, Seikh AH, Sherif ESM. Entropy generation and dual solutions in mixed convection stagnation point flow of micropolar Ti6Al4V nanoparticle along a Riga surface. Processes. 2020;8(1):1–14. https://doi.org/10.3390/pr8010014.

Satyanarayanaraju CV, Dixit R, Miryalkar P, Karunanidhi S, AshokKumar A, NagaLakshmi J, et al. Effect of heat treatment on microstructure and properties of high entropy alloy reinforced titanium metal matrix composites. Mater Today Proc. 2019;18:2409–14. https://doi.org/10.1016/j.matpr.2019.07.088.

Khan SA, Hayat T, Alsaedi A, Ahmad B. Melting heat transportation in radiative flow of nanomaterials with irreversibility analysis. Renew Sustain Energy Rev. 2021;140: 110739. https://doi.org/10.1016/j.rser.2021.110739.

Khan SA, Hayat T, Alsaedi A. Entropy optimization in passive and active flow of liquid hydrogen based nanoliquid transport by a curved stretching sheet. Int Commun Heat Mass Transf. 2020;119: 104890. https://doi.org/10.1016/j.icheatmasstransfer.2020.104890.

Hayat T, Khan SA, Khan MI, Alsaedi A. Theoretical investigation of Ree-Eyring nanofluid flow with entropy optimization and Arrhenius activation energy between two rotating disks. Comput Methods Programs Biomed. 2019;177:57–68. https://doi.org/10.1016/j.cmpb.2019.05.012.

Khan SA, Saeed T, Khan MI, Hayat T, Khan MI, Alsaedi A. Entropy optimized CNTs based Darcy–Forchheimer nanomaterial flow between two stretchable rotating disks. Int J Hydrogen Energy. 2019;44(59):31579–92. https://doi.org/10.1016/j.ijhydene.2019.10.053.

Khan SA, Hayat T, Khan MI, Alsaedi A. Salient features of Dufour and Soret effect in radiative MHD flow of viscous fluid by a rotating cone with entropy generation. Int J Hydrogen Energy. 2020;45(28):14552–64. https://doi.org/10.1016/j.ijhydene.2020.03.123.

Hayat T, Khan SA, Alsaedi A. Simulation and modeling of entropy optimized MHD flow of second grade fluid with dissipation effect. J Market Res. 2020;9(5):11993–2006. https://doi.org/10.1016/j.jmrt.2020.07.067.

Shutaywi M, Shah Z. Mathematical modeling and numerical simulation for nanofluid flow with entropy optimization. Case Stud Therm Eng. 2021;26: 101198. https://doi.org/10.1016/j.csite.2021.101198.

Marzougui S, Mebarek-Oudina F, Assia A, Magherbi M, Shah Z, Ramesh K. Entropy generation on magneto-convective flow of copper–water nanofluid in a cavity with chamfers. J Therm Anal Calorim. 2021;143(3):2203–14. https://doi.org/10.1007/s10973-020-09662-3.

Matin MH, Pop I. Forced convection heat and mass transfer flow of a nanofluid through a porous channel with a first order chemical reaction on the wall. Int Commun Heat Mass Transf. 2013;46:134–41. https://doi.org/10.1016/j.icheatmasstransfer.2013.05.001.

Qasim M, Hayat Khan Z, Khan I, Al-Mdallal Q. Analysis of entropy generation in flow of methanol-based nanofluid in a sinusoidal wavy channel. Entropy. 2017;19(10):490. https://doi.org/10.3390/e19100490.

Khan A, Khan I, Ali F, Shafie S. A note on entropy generation in MHD flow over a vertical plate embedded in a porous medium with arbitrary shear stress and ramped temperature. J Porous Media. 2016. https://doi.org/10.1615/JPorMedia.v19.i2.50.

Khan I, Hussanan A, Saqib M, Shafie S. Convective heat transfer in drilling nanofluid with clay nanoparticles: applications in water cleaning process. Bio Nanosci. 2019;9(2):453–60. https://doi.org/10.1007/s12668-019-00623-1.

Acknowledgements

The authors acknowledge the financial support provided by the Centre of Excellence in Theoretical and Computational Science (TaCS-CoE), KMUTT. The authors wish to thank the anonymous referees for their comments and suggestions.

Author information

Authors and Affiliations

Contributions

DK model the problem. DK and IK solved the modeled problem analytically. DK and IK draw the graphs. Results and discussions have reviewed by PK and WW reviewed the whole manuscript. Proof reading has performed by DK and PK. All authors reviewed the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khan, D., Kumam, P., Watthayu, W. et al. Heat transfer enhancement and entropy generation of two working fluids of MHD flow with titanium alloy nanoparticle in Darcy medium. J Therm Anal Calorim 147, 10815–10826 (2022). https://doi.org/10.1007/s10973-022-11284-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11284-w